2 2

PLUMBING CONNECTION Summer 2017

Aquaknect Flexibles general manager

Tom Davies says he also has concerns

about the wire size being used on the

braiding as a weaker braid is more

likely to fail. The company, which is an

Australian manufacturer of flexible

braided connectors, uses a minimum

wire size for braiding of 0.23mm.

“This is the minimum for us but there

are some manufacturers where the

largest wire is 0.15mm, which is 33%

thinner, and you can see through the gaps

to the rubber underneath. With the tap

being turned on a few thousand times,

the hose flexes back and forth, causing a

weaker braid to fail regardless of whether

the braid has broken,” says Tom.

“Additionally, less mass means

quicker corrosion.”

There are suggestions that these low-

quality products are able to make it to

market by unscrupulous suppliers that

are defrauding the WaterMark product

certification system with what’s known

as the ‘golden sample’.

The ‘golden sample’ is when a

product supplied for third-party

testing is of a high enough quality to

pass requirements but the product

supplied when large orders are placed is

substituted with a low-cost alternative.

FUME CUPBOARDS

Common household cleaners kept

under sinks and cupboards create

a ‘fume cupboard’ environment in

areas where flexible braided hoses

are installed and is a potential second

source of corrosion causing flexible

connectors to burst.

The presence of stored household

cleaners in closed environments causes

the level of chlorine in the air to rise

to measurable levels because many

common cleaners contain chlorinated

chemical solvents, liquid chlorine or

crystallised chlorine chemicals. These

remain in the air long after the product

has finished being used.

“In most cases cleaning products are

stored in bathroom, kitchen or laundry

sink cabinets where there is high

humidity caused by condensation from

hot water being run through the taps

and bowls above the cabinet,” says Tom.

“Chlorine dissolves in humidity and

forms hydrochloric acid, which is highly

corrosive. Therefore the number of

failures in this environment caused by

corrosion is high.”

Cheryl from IAG says that the

company’s research backs up this

claim, with IAG data suggesting flexible

braided hoses eroded faster if household

cleaners are stored under the sink.

PLUMBING INDUSTRY RESPONSE

Starting a discussion about the issue

of bursting flexible braided hoses is an

important first step but action needs

to be taken to bring the problem to the

attention of regulators, government,

TAFE’s, manufacturers and consumers.

“It’s still only a small percentage of

the industry that realises this issue is

happening,” says Trevor.

At the workshop hosted by

Plumbing

Connection

, there was consensus that

the current AS/NZS3499:2006

Water

supply – Flexible hose assemblies

needs

to be updated.

“Changes to the Standard need to

reflect technology and practicality. The

current version was last reviewed in

2006, with a small amendment in 2009,

and since then there have been many

regulatory and technological changes,”

says Tom.

There are also concerns that

manufacturers are actually writing their

own interpretation of the Standard,

with one supplier on the shelves of a

prominent Australian outlet providing

a selective product warranty that

“covers domestic use only and not for

commercial applications”.

Representatives at the workshop

discussed the possibility of proposed

changes to the Standard, including

introducing a minimum wire diameter

for the stainless steel braid, future

testing for things like corrosion,

markings on the inner liner of hoses to

identify manufacturer and changes to

the classification of hoses.

Trevor agrees that there are things

within the current Standard that are

not ideal but says because many of the

issues causing burst flexible connectors

may be the result of incorrect

installation, a change to the Standard

will not have much of an impact.

“The manufacturers and suppliers

of these hoses need to implement

specific requirements about how flexible

hoses are installed and maintained. I

think that’s probably going to solve a

lot more problems compared to the

Standard.”

Regardless of how the industry

decides to take this issue forward, it’s

important that action is taken soon.

“Unless the whole industry gets

together and does something, we will

still be talking about this in a few years,”

says Shinners Plumbing owner Kevin

Shinners.

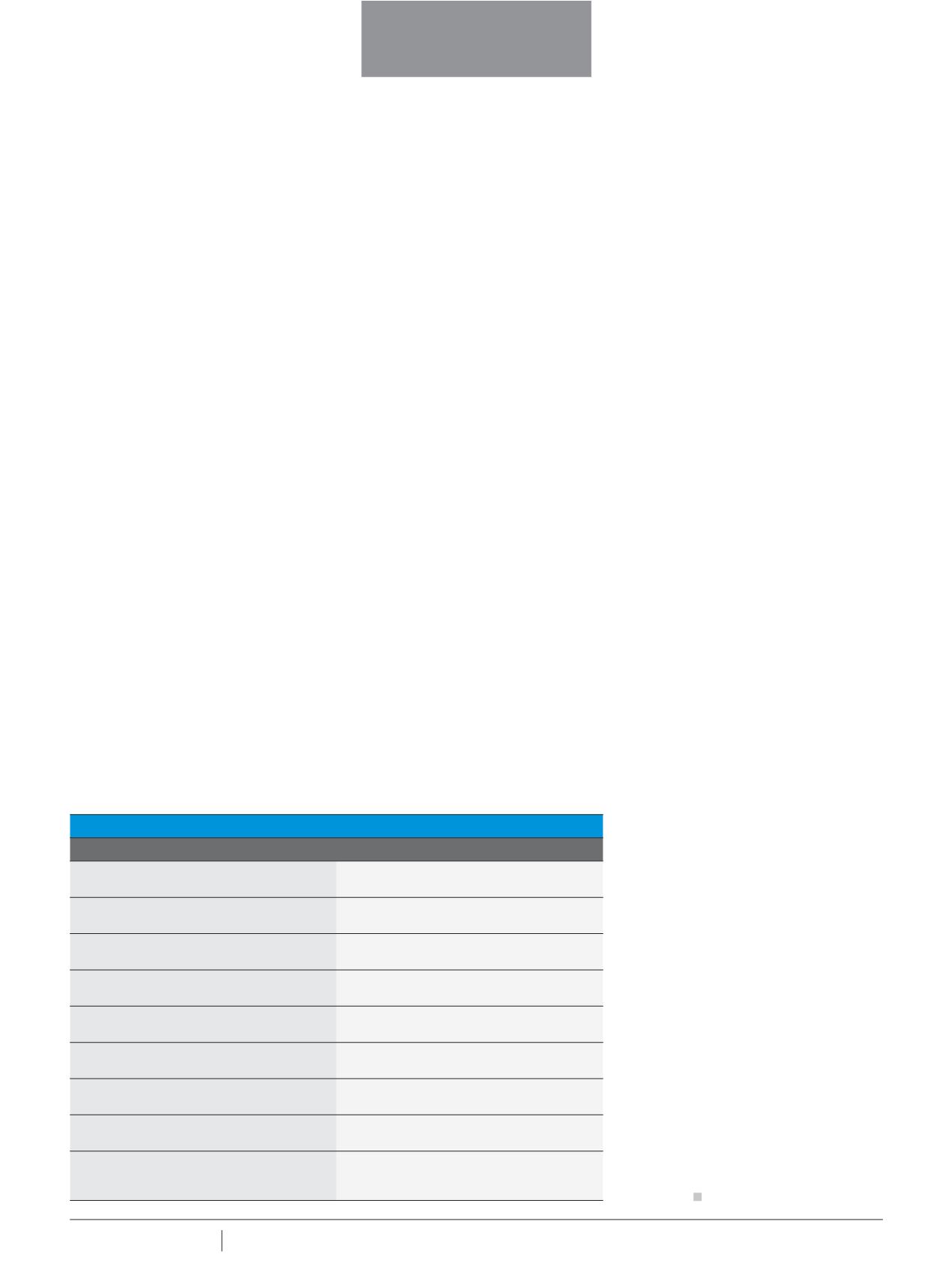

COVER STORY

FLEXIBLE BRAIDED HOSES

FLEXIBLE CONNECTORS

THE QUESTION IS

RECOMMENDATION

How do I tell good from bad, when installing

flexible connectors?

Approved product will carry WaterMark

identification and its certifier number.

What does the brand warranty tell me?

Use one that has clauses that don’t get you

into hot water.

How old is it and how long ago was it installed?

More than 10 years and any flexi should

probably be replaced.

Is it good quality – thick braiding, good

fittings?

Cheap and cheerful – if it is too good to be true,

then look for alternatives.

Is there high water pressure on site?

Consider a pressure reduction valve to limit

pressure shock through the flexi hose

Are there cleaning products in the same

cupboard?

Suggest a vent hole to allow regular airflow in

and out to reduce chloride levels.

Are there signs of water drips or rust on the

flexi hose?

Could be a ticking time bomb, replace before

failure.

Does the flexi suit the temperature and

pressure of the site?

Replace it with a more appropriate flexi hose

that’s up to the task.

Does the homeowner’s insurance policy

restrict or exclude cover for losses arising

from flexi hose failures?

Suggest a regular maintenance regime, copper

or change insurer.