www.plumbingconnection.com.au

www.plumbingconnection.com.au

1 9

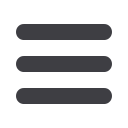

“Once the water reaches 60°, the

evaporation process leaves behind

a deposit of chloride. Over time the

process continues and the chloride level

increases in the deposit until it reaches

a level that enables localised corrosion

of the stainless steel to occur. Since

the cracks caused by stress corrosion

cracking are so fine, they are difficult to

detect,” says Geoff.

This corrosion eats away at the

individual metal strands of the steel

sleeve, which eventually fail and break.

When enough of these strands fail, the

steel sleeve is no longer able to support

the inner lining and water pressure

causes the lining to bulge out of the

sleeve. This leads to the lining rupturing

and water escaping.

The presence of water exterior to the

hose is required for corrosion, which

is why most failures are seen under

kitchen, laundry and bathroom sinks,

toilets and dishwashers, rather than on

connectors to gas stove cook-tops.

Materials Solutions Australia (MSA)

engineering director Trevor Rowlands

says pulling apart burst flexible

connectors clearly shows the moisture

path and evidence of corrosion.

“Stainless steel isn’t impervious to

corrosion and can become vulnerable

when put through certain conditions.

However, the stainless steel braiding is

appropriate for its function and it’s the

leakage at the connection that is the

issue. You can always trace a leak path

in these hoses and all the ones I’ve seen

have had a leak path at the connector.”

WHY IS THIS HAPPENING?

There are various reasons why this

leakage occurs but four main issues

arise based on experience in the field.

These are installation, the effects of

water hammer, the quality of materials

in the manufacturing process and

household cleaning products being

stored within the vicinity of flexible

braided hoses in homes.

COVER STORY

FLEXIBLE BRAIDED HOSES

The stainless steel braided sleeve

corrodes, causing the rubber inner tube

to expand and burst.

Image supplied by

Neil & Craig Baker Plumbing - NSW.