2 0

PLUMBING CONNECTION Summer 2017

Other than poor quality, the majority

of these reasons are not due to the

connector itself, which suggests the

issue of bursting flexible hoses is largely

preventable.

INSTALLATION

Russell and Trevor both suggested

installation issues are playing a big

role in bursting flexible braided hoses,

particularly in regards to the tightening of

the nuts at either end of the connectors.

“Where the nut is connected at one end

under the sink or to the mains water its

fine but when it comes to tightening up

the second nut, which connects to the tap

assembly, the design is such that the first

nut can become loose,” says Trevor.

“When you tighten the first nut, the

second nut can actually partially loosen

off again if the ferrule isn’t gripped or

held at the first end.”

This slight loosening leads to a slow

leak that allows water to migrate across

the rubber seal face down to the back

face of the nut and eventually onto the

braiding.

Tightening the nuts is also an issue

where the installing plumber hasn’t

torqued one or both of the nuts

sufficiently. If it’s too loose it creates a

leak path and if it’s too tight the seal will

rupture.

“These end in the same result, which

is corrosion of the stainless steel

braiding, leading to wire breakage and

then the rubber tube expanding and

bursting,” says Trevor.

The rise of the DIY culture in Australia

and the low cost of these connectors

are also increasing the likelihood of

flexible hose failures, as they encourage

handymen to attempt installations

themselves.

General insurer Budget Direct says on

its website that this is compromising

the integrity of flexi hoses in homes as

DIY is more likely to result in flexible

hoses being damaged at the time of

installation, which then increases the

chance of bursting.

There are fears that eventually

insurance companies will begin

disallowing claims if customers can’t

prove installation by a licensed plumber

as well as regular maintenance.

“There’s a significant risk here for

the home owner and it’s likely to get

far worse given the high rate of losses

insurers are currently reporting due

to these flexible connectors,” says

Metropolis chartered loss adjuster

director David Pockett.

EFFECTS OF WATER HAMMER

Although by itself water hammer will

not cause failure, it is a contributing

factor that can play a role in the final

catastrophic failure of a flexible braided

hose once it has been brought to a

vulnerable point.

Phillip Woolhouse has more than 30

years experience in the plumbing sector

and is the principal consultant at Phil

Woolhouse Hydraulics in Perth. He says

the speed at which modern tapware can

be isolated puts the rubber seal under

constant force.

“Mixer taps can be closed in a fraction

of a second and the faster the tap is

isolated, the higher the pressure shock.

Pressure well above 500kpa can be

experienced by modern fast-closing

tapware and this generates massive

shock pressures within the piping

system.”

According to Trevor, this can cause

the rubber seal to react by compressing

over time and forming a permanent

stress.

“Some rubber does have a memory

effect and will shrink. Over time this

loosens the nut and there’s less contact

pressure on the seal face, allowing

water to leak.”

QUALITY OF MATERIALS

With the price of flexible braided

hoses continuing to drop and a number

of new products entering the market,

there are concerns that the quality of

steel and brass components being used

in some hoses are contributing to the

early failures being seen in the field.

Trevor says he has come across

flexible braided hoses where the

brass barb fittings were not properly

manufactured or heat treated.

“Alpha-beta brass had been used,

which is cheaper but more susceptible

to de-zincification corrosion, and had

not been carefully controlled during

the manufacturing and thermal cycling

process. The aim is to produce a

microstructure with ‘islands’ of beta

phase but when they interconnect,

forming a continuous network, once

corrosion occurs it creates a continuous

pathway allowing water to pass through

the cross-section of the barb fitting

from the inside to the outside surface.

The water is then in direct contact with

the area where the rubber tube of the

hose and the stainless steel braiding are

crimped.”

COVER STORY

FLEXIBLE BRAIDED HOSES

CONSIDERATIONS FOR PLUMBERS

Below are five key considerations for

plumbers when specifying and installing

flexible hoses from attendees at the

Plumbing Connection

flexible hose workshop.

1. Ensure you purchase the correct length of

hose for the installation. It’s better for the

hose to be too long rather than too short

as this allows the hose more space and

reduces stress on the connections.

2. Ensure the connections are firm and leak

free.

3. Offer to routinely inspect flexible

connectors as part of a regular

maintenance in all premises that you visit.

4. Be prepared to pay slightly extra for

a quality connector from a reputable

supplier that offers a credible warranty.

5. If you become involved in a flexible hose

failure, photograph the hose in detail and

in situ with context photos. Retain the

photos securely and the hose in a sealed

bag as evidence with clear labeling. Only

release this item directly to an independent

material testing expert who signs for it.

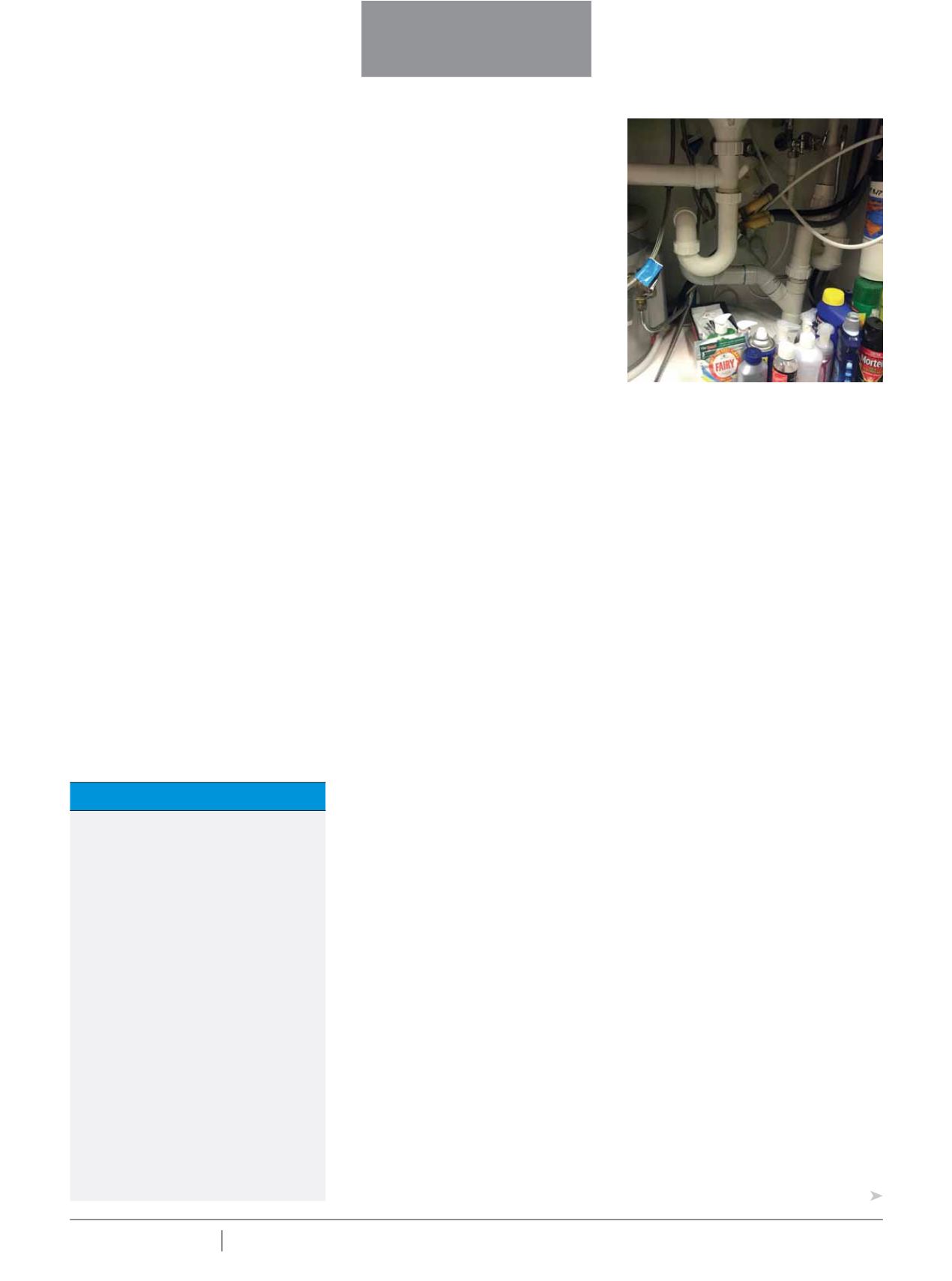

Common household cleaners stored

under kitchen or bathroom sinks where

flexible braided hoses are installed can

create fume cupboard environments

that corrode the braided stainless steel

sleeve, leading to bursting hoses.