3 6

PLUMBING CONNECTION

SUMMER 2016

Flow rate testing is done for both high pressure

applications – mains water fed showers – and low pressure

showers which are gravity fed systems. The Standard refers

to both ‘low pressure’ and ‘uneven’. Uneven is a difficult one

because it isn’t truly covered in the Standard at this stage

but it is reviewed in a sense of the output. Unevenness can

be caused by one side being fed through mains, with the

other being gravity fed. Another instance of uneven pressure

occurs when a thermal device is installed that will only

actuate under certain temperature controls.

“At the moment we are testing for high pressure

applications at 150, 250 and 350kPa. We also test at

500kPa but we only take 150-350kPa as the nominal. For

low pressure applications we test at 35kPa.”

Despite users not simply going from say 0kPa to

250kPa, testing labs must be consistent in their approach

and conduct tests in one direction. If they overshoot the

mark, they can’t just bring it back up either as they will take it

back down a different flow path, so they have to start again.

“Users don’t just turn a shower on and off. They turn it on,

twist the handles higher and lower and do so until they find

the optimal flow rate and temperature.

“We need to be consistent though. Labs need to have

a consistent approach to all of this because that is what

is being expected by the Conformity Assessment Bodies

and that’s what is expected by our clients. They want to be

assured that what we are producing for them is of quality

and consistency.”

Mean spray spread testing has been around a long time but

as Stephen explains, it was based on round shower heads. As

you would be well aware, shower heads now come in a variety of

shapes and sizes, from oversized rectangles to triangles even.

“We no longer simply just use round shower heads. The

standard addresses this in a number of ways by looking at

‘area’ so we need to take that into consideration when testing.

It is also important to understand what type of hole pattern

each shower head possesses. We look to see if they use

evenly spaced holes, circular patterns, linear patterns etc.

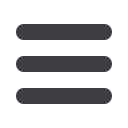

“We are looking for consistent patterns across the spread

of the user, as well as the angle. You don’t want a really small

showerhead throwing out a very wide angle.

“Showers are probably one of the only Standards that

really take into consideration the user’s comfort which is

pretty unique and it also takes in the effectiveness of the

shower itself. With that in mind, we look for consistency of

warmth on the torso. If users aren’t getting that warmth

across their body, they aren’t going to want to shower for

long,” Stephen says.

It’s been well documented that change was coming

because even in the old

AS/NZS 6400:2005 Water efficient

products - Rating and labelling

there was a label that

suggested manufacturers could have a 3 star shower head

that performed at less than 7.5 litres per minute.”

WELS

IMAGE 1:

Testing considers consistent warmth of water

across the entire torso.

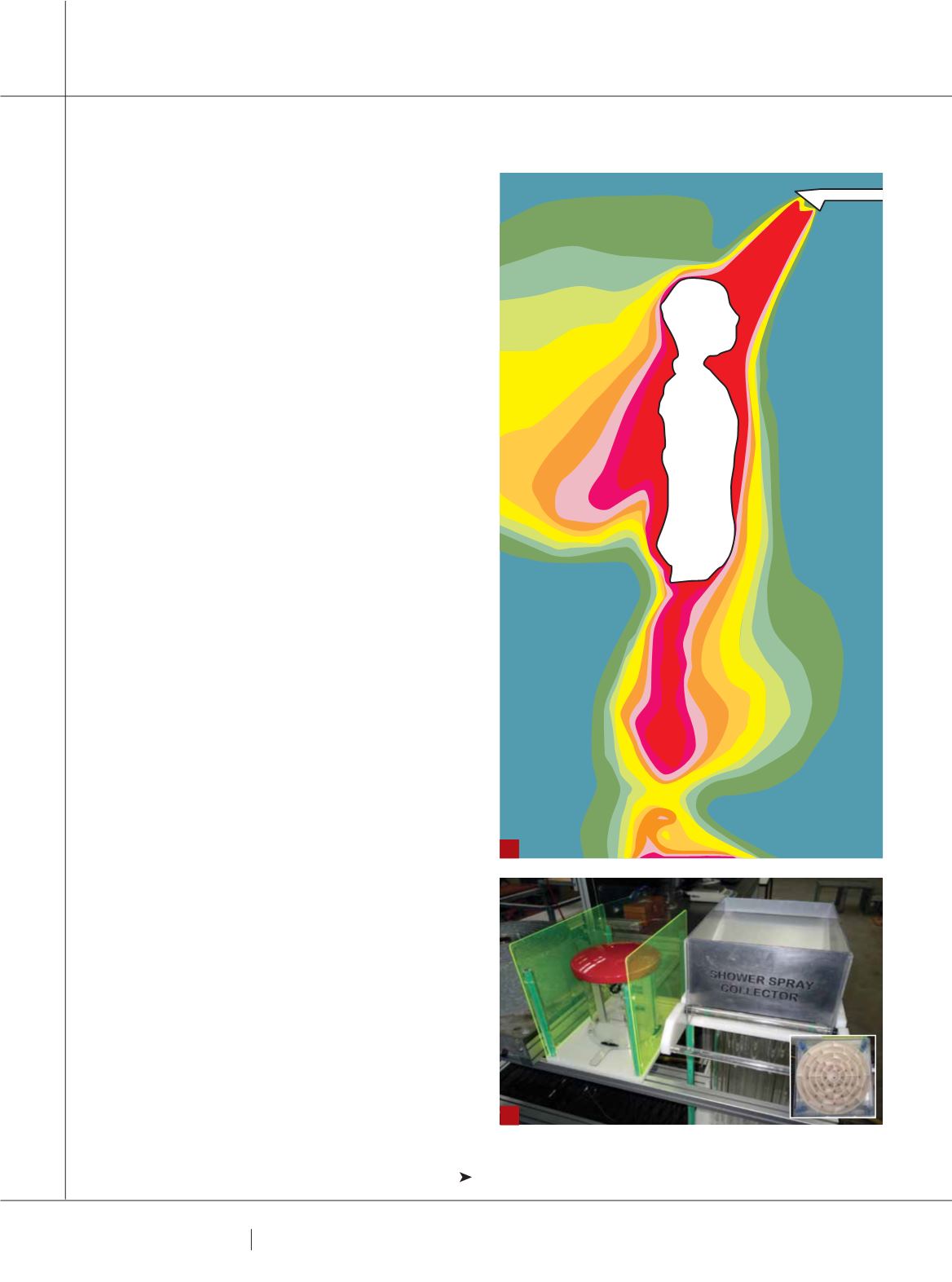

IMAGE 2:

Force and coverage tests

are now in place using high tech equpiment.

1

2