3 8

PLUMBING CONNECTION

SUMMER 2016

“The the force and coverage tests came in as an informative

which is different to a normative. It is still an informative, but

due to AS/NZS 6400:2005 and ITS labelling scheme; nothing

has changed from 0-3 stars, but with this extra column:

compliance with spray, force and coverage, you’ve got the

Range E (6-7.5 litres per minute) and Range F (4.5-6 litres per

minute).

“If a manufacturer is producing a nominal flow within

those bands it needs to now look at these two tests. They

are informative but in essence become a mandatory

requirement for the labelling,” Stephen says.

To facilitate the force and coverage requirements, CSIRO

developed an impressive new test rig. A dome featuring a

load cell underneath measures the force aspect.

“We push water through at 150, 250 and 350kPa onto

the dome for this particular standard. We look at the mains

flow at each of those water pressures hitting the dome at a

distance which is pretty much consistent with all the other

distances we use across our performance testing. And then

we measure the average of the water at 150, 250, 350kPa.

“Water is obviously hitting the dome which means it will

move a little bit (grams force).

“The average for the criteria now is looking at greater

than 85 grams force. We are looking at that number as users

require enough water to get soap and suds off the skin and

hair. It is imperative to maintain a short shower (Aus suffers

from droughts) and come out refreshed and clean.

“For very low flowing shower to achieve this,

manufacturers may need to increase velocity by tightening

up on the nozzles or create a wider spread of these flow

nozzles. It might actually mean the manufacturers have to

go back to the drawing board because their standard shower

might not produce that, so that can be a challenge.

The second part of the testing rig looks similar to the old

angular testing gauges but it features some significant

differences.

“We’re collecting water in tubes that sit below the shower

head pattern. Once these tubes are collected over a period

of time, we then measure those tubes and get a pattern. We

analyse where the water falls to observe patterns. It gives

you a visual display whereas the means spray spread angle

only provided an idea of the angle.

“The other factor to consider is the criteria, which has

changed as well. This takes into consideration the volume

and collection within the zones. We have a zone in the middle

and then a zone 1, 2, 3, 4, 5 and 6 which refers to the tubes

and their positioning.

“To ensure we get consistency, we want that spread of

evenness across the spray; we’re looking at the standard

deviation. Users want consistency across the zones on low

flowing showers.”

It is a requirement to have some flow in the middle of

the showerhead for manufacturers to achieve a rating. If a

manufacturer creates a shower head without it, they won’t

bother with this test.

It doesn’t necessarily tell you where the flow is, in the

middle or the outer, it’s not giving you that information.

The fact that this new test tells you exactly where the flow

is coming from is a huge leap when it comes to looking

at a 4 star rated shower. It’s a much better approach to

understanding the patterns and flows. It’s quite a complex

rig and we have spent a long time getting it right; however,

it’s been well worth the effort as the results not only benefit

our clients, but importantly, it will mean users will be able to

make a more informed choice when selecting a shower head

in the future.”

While Stephen believes the new testing rig is a great

accomplishment and that WELS is going in the right

direction, he believes there is some further improvement

needed.

“There are certain areas that need to be looked at from a

more holistic sense which can sometimes be difficult when

using a standard as a ‘one method suits all’. That’s still a

challenge, in my opinion, but I think it can be overcome,

over time. As technologies grow and change, obviously the

willingness of Standards committees to invest more time

and effort will also come into effect.”

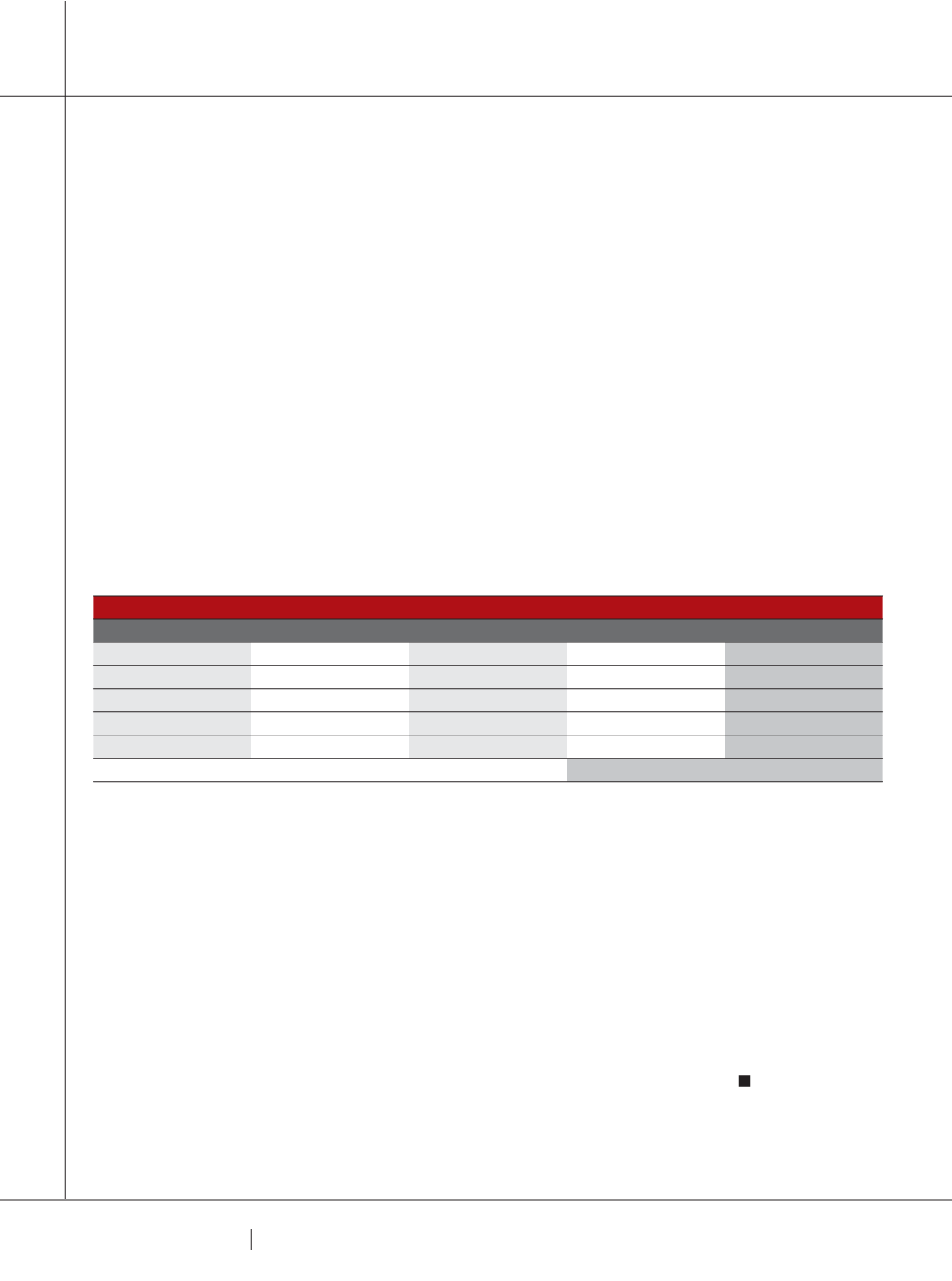

PRESSURE AND FLOWRATES

INCREASING 1

FLOW RATE

INCREASING 2

FLOW RATE

FLOW RATE

Pressure kPa

L/min

Pressure kPa

L/min

Average L/min

150

7.52

150

7.52

7.52

250

8.53

250

8.53

8.53

350

8.58

350

8.58

8.58

500

9.32

500

9.32

9.32

Nominal flow rate (average of 150 to 350 kPa)

8.21

L/min

CSIRO

www.csiro.auWELS

www.waterrating.gov.auWELS