4 2

PLUMBING CONNECTION

SUMMER 2016

If the downstream raises above the set pressure, the

pressure under the diaphragm assembly pushes it up and

the attached seal disc also raises up to decrease the valve

opening. This continues until an equilibrium is reached

between the valve spring tension and the downstream

pressure, thereby maintaining the downstream pressure set

point.

Direct Acting PRVs, especially in sizes of 40mm diameter

and below, are able to effectively control the downstream

set pressure provided they are correctly sized for the flows

passing through them.

These valves require a relatively stiff spring to operate.

There can be issues that may arise with Direct Acting PRVs

due to that stiff spring. This is especially applicable for

valves sized 40mm and above.

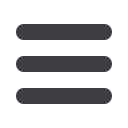

FALL OFF IN DOWNSTREAM PRESSURE

SIZES 1¼”, 1½”, 2” (32, 40, 50MM)

10

30

50

70

90

110 gpm

0

5

10

15

20

25

psi

0

34

69

103

138

172

kPa

38

114

190

266

342

418

lpm

REDUCED PRESSURE FALL-OFF

1¼”

1½”

2”

VALVE CONTROL

RUSS DUNNE

A Pilot Operated and Direct Acting PRV.

The effect of spring stiffness – called hysteresis – can be:

1. A rise in the downstream pressure above valve set point,

particularly at low flow or zero flow.

2. A delay in reaction to a rapid change in flow demand from

users, resulting in a drop in the downstream pressure

below its set point.

Charts provided by the Direct Acting PRV manufacturers

detail the ‘fall off’ in the downstream pressure from its set

point, over a range of flows.

As a result, you should be aware – and allow for – the

possible increase in downstream pressure at zero flow, as

well as the possible drop off in downstream pressure at

rapid change in flow, particularly in the larger valve sizes.

Generally this style of valve can be used; however, the

advent of VSD pumps in high rise building applications for

potable water supply has changed the requirements of

pressure reducing valves to deal with rapid changes in

flows. VSD pumps ramp up and down based on pressure and

flow fluctuations within the system and have a determining

effect on what valve is best suited to the application.

The second group of pressure reducing valves are Pressure

reducing valves are “hydraulically actuated diaphragm

control” or more commonly known “Pilot Operated PRV’s”.

These PRVs use a small adjustable pilot valve, plumbed

onto the main valve. The pilot acts as the PRV ‘brain’,

sensing the downstream pressure and regulating the water