7 0

PLUMBING CONNECTION

SUMMER 2015

The most obvious difference between the original

Appendix R of the current AS/NZS 5601-1-2013 and the

rewrite is the title itself.

The current version was clearly titled ‘Spillage Test

for Flued Appliances’. This is not the case in this latest

amendment – in fact no title is evident.

What is stated under Note 3 of Clause R1 is: “This

appendix does not apply to room sealed appliances.” This

would include balanced flue and power flue gas heaters.

The most obvious question now is – why?

FLUE DESIGNS

Basic flue designs used in domestic installations include

conventional type flues (discharging combustion products

to the atmosphere only), balanced flue appliances and power

flue appliances.

At the moment most existing gas heaters are flued only

to the atmosphere, and air for combustion at the burner is

obtained from within the building.

Balanced flue and power flue appliances also discharge

combustion products to the atmosphere, but they provide

external air for combustion at the burner.

Drawing air for combustion from an external source rather

than from within a building is a much cleaner and safer

proposition than using room air.

The potential to draw combustion products down a

heater with a conventional flue when fans in the building are

operating is far greater than for a balanced flue or power

flue design. However, it’s not impossible under certain

conditions.

To explain this, look at the history of central heating units.

Initially these were in a cupboard in a building that itself was

ventilated to the atmosphere to provide air for combustion.

A conventional flue separately discharged combustion

products to the atmosphere.

Over time, due to space limitations, central heaters were

installed in ceilings and/or underfloor spaces. Then design

features such as slab floors became commonplace, so the

central heating unit was placed outdoors.

Air for combustion was plentiful, and unsightly flues

were not required as everything became compact in the

appliance.

One problem did remain. As with all gas appliances

incorporating a heat exchanger that divides combustion

products from the warm room air, the heat exchanger can

fail. It may crack over time, or seals may fail to prevent

combustion products and room air mixing.

This is a potential source for carbon monoxide (CO) to

affect the interior of the building.

That same scenario applies to balanced flue and power

flue gas heaters.

Gas Information Sheet No 38 requires the warm air

discharge outlets of an external central heating unit to

be checked for CO because of concerns about the heat

exchanger cracking or seals deteriorating.

On this basis alone one has to wonder why the AS 601

committee decided not to enforce similar CO testing for

balanced flue and power flue gas heaters.

The committee may have considered that some

appliances have included pressure switches designed to

turn off the gas if any cracks or seal faults become evident

in the heat exchanger.

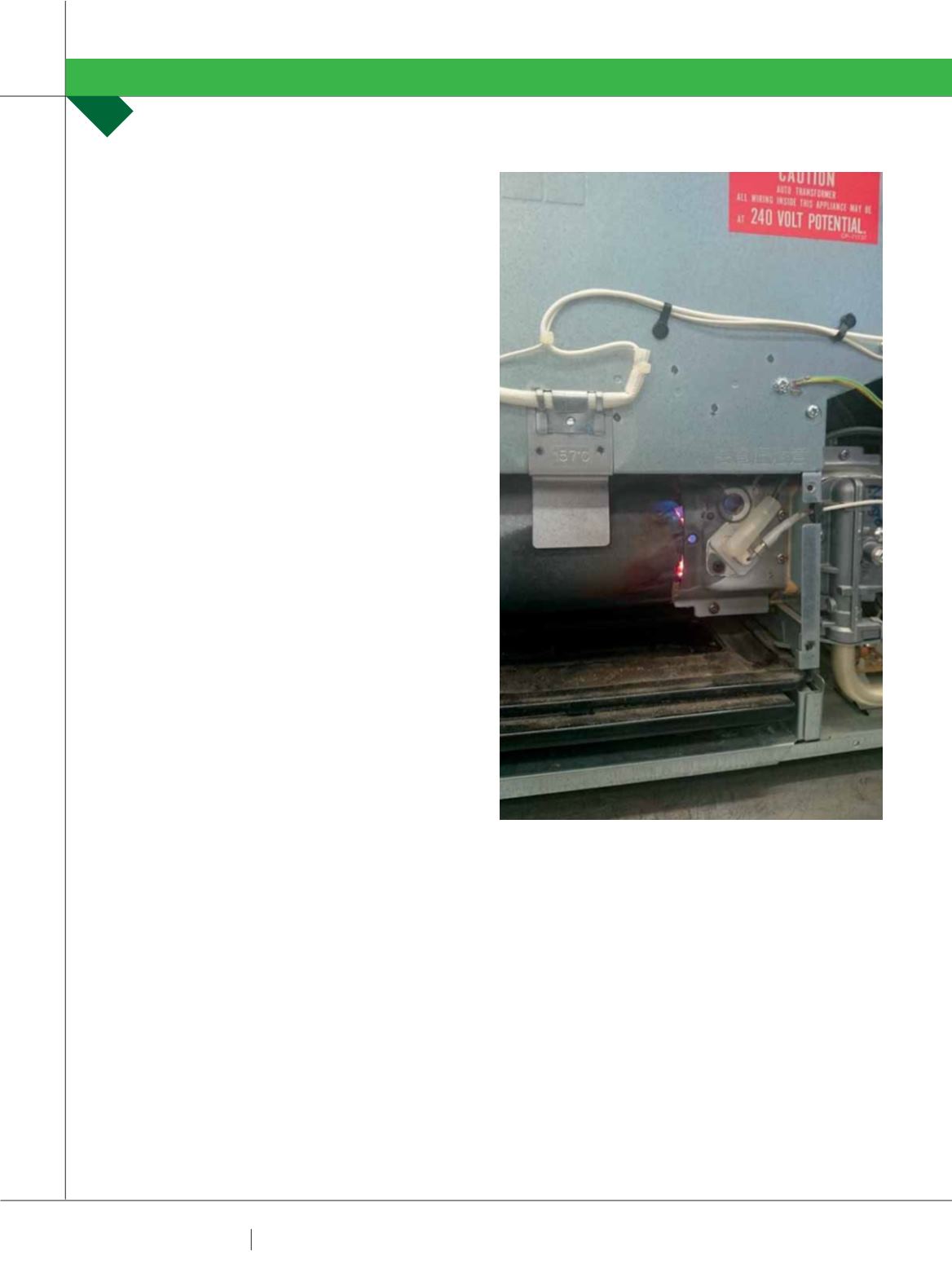

However, the accompanying photograph of a power flue

appliance shows damage around a sealed area of the heat

exchanger. This appliance was still operating with two holes

in the heat exchanger.

Unfortunately, as with a gas heater that is conventionally

flued to the atmosphere, fans in a building can draw

GAS MATTERS

ROGER LAMBIE

This heat exchanger is still in operation, despite two obvious

holes appearing.