6 8

PLUMBING CONNECTION

SUMMER 2015

SAFETY:

A BURNING ISSUE

H

ere’s a popular paradox that is especially relevant

in today’s fast-moving world: change is the only

constant.

During a discussion about the Type A side of gas installations

and service procedures a friend said ‘we cannot dwell on the

past.’ New technologies and methods should be embraced.

I agreed, because I had attended a training development

group in which we were given the ‘change’ and asked to

expand on what it meant to individuals and groups.

Innovations in any field will always be ahead of the

Standards.

When a product has surfaces that are quite hot during

operation but it meets the Standard for that product, then

the safety criterion is met.

However, if innovation causes heat and potential danger

in areas not normally covered by a Standard, this should be

tackled immediately.

Some readers may recall the article ‘State of Confusion’

in the summer 2014 issue of

Plumbing Connection

. It

included a reference to one of the findings in a report by

the Australian Gas Association as commissioned by the Gas

Technical Regulators Committee regarding carbon monoxide

safety measures:

∫ The level of negative pressure required to cause a flow

reversal when the heater was operating was typically less

than 4Pa and as low as 2Pa in one case. This is what can

happen to a flue that is already warm.

∫ The negative pressure required to prevent normal flow

establishment was, as might be anticipated, even lower at

between 2Pa and 1Pa. This is what can happen when the

flue is cold.

The procedure – described in Appendix R of AS/NZS

5601.1:2013 where all fans had to be turned on prior to

operation of the gas appliance and the flue getting warm –

challenged potential safety aspects for the operator and the

consumer.

The main theme of the ‘State of Confusion’ article was

to highlight the difference between requirements in the

Appendix R spillage test for flued appliances and those in

Gas Information Sheet No. 38 produced by Energy Safe

Victoria (ESV).

They are quite different in their application and in what

plumbers and gasfitters are legally bound to follow.

A recent draft put for public comment on AS/NZS

5601.1:2013 Amd 2:2015 that includes a rewrite of

Appendix R still raises concerns as to its practicality.

CHANGE FOR THE SAKE OF CHANGE CAN LEAD TO RISKY SITUATIONS.

ROGER LAMBIE

OUTLINES SEVERAL

CONCERNS HE SEES ABOUT TESTING FOR CARBON MONOXIDE.

GAS MATTERS

ROGER LAMBIE

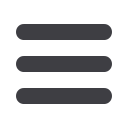

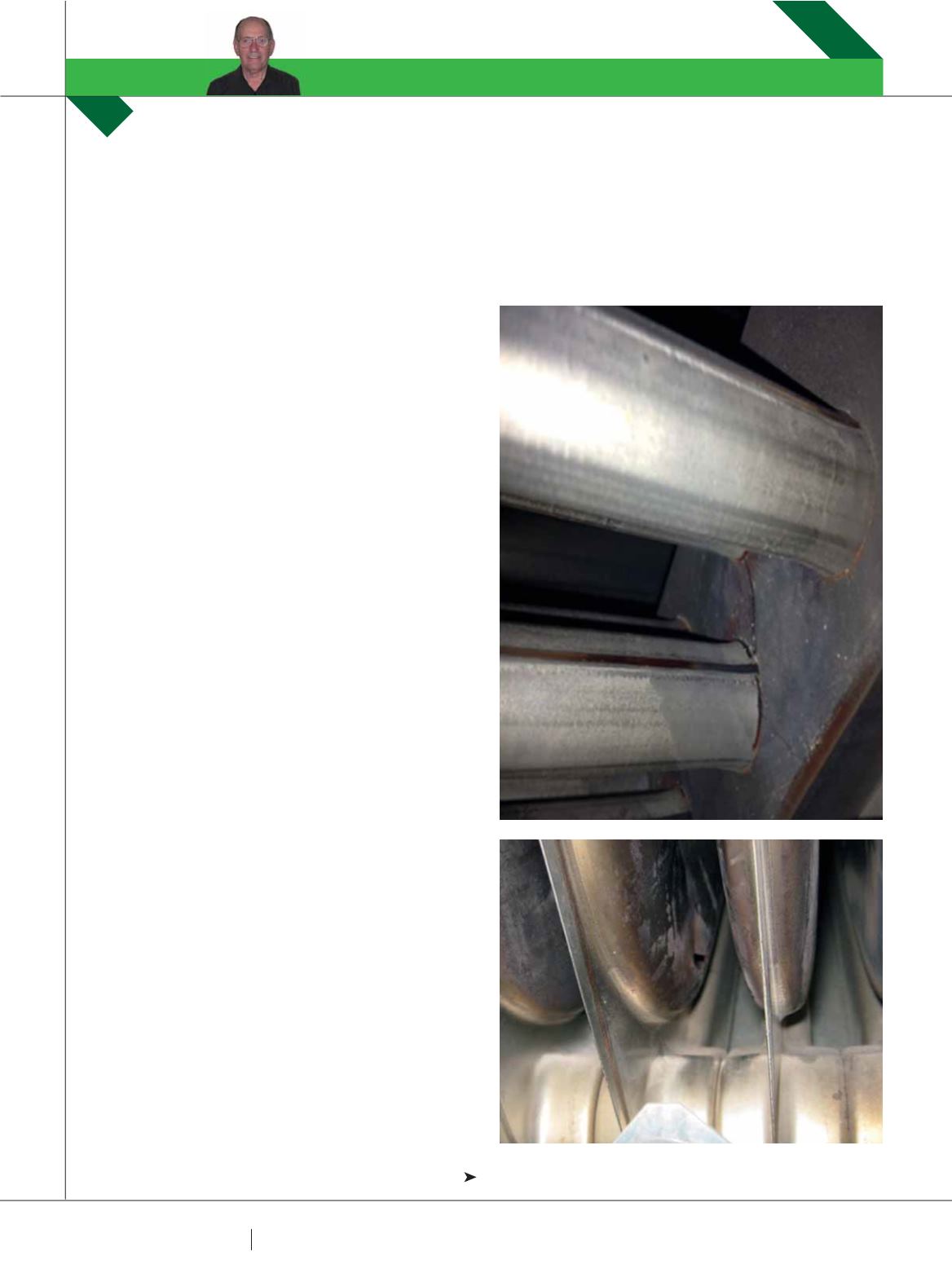

Heat exchangers can fail due to cracks or seals opening up

over a period of opertional use.