74

PLUMBING CONNECTION

SUMMER 2015

A GLIMPSE BEHIND THE CURTAIN

A

s I have mentioned in previous articles, I run a

website that supplies a broad range of parts for all

sorts of repairs and installations of solar hot water

products. One of the more popular brands on the website

is RESOL who manufactures a wide range of system

controllers in the fields of solar hot water, swimming pools,

heating systems etc.

Due to my involvement with RESOL and supplying the

brand to plumbers all over Australia, I was fortunate

enough to be invited to a tour of the RESOL headquarters

based in the small and rather idyllic German town

of Hattingen. I had expected Germany

to be very neat and proper, but wasn’t

prepared to find this tidiness and efficiency

permeating the whole production plant.

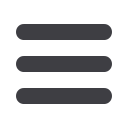

We were lucky enough to be able to see the

entire production line in action and once we

saw how efficiently the quality controller

was produced it became easy to see why

RESOL is becoming such a sought after

product for the replacement market here in

Australia. The facts and figures speak for

themselves: RESOL products optimise the efficiency of more

than 3 million systems in over 60 countries.

The DeltaSol® BS/4 and BS plus (one of RESOL’s most

popular products) were being produced while we visited and

we followed the production from start to finish. Everything

starts in the circuit board assembly, where the SMD

components are mounted. SMD stands for Surface-Mounted

Device, which means the parts used here are so tiny that

a machine is needed to place them correctly. In RESOL’s

state-of-the-art production plant, the SMD machine is by

far the largest. It places tens of thousands of tiny little parts

per minute, precise to the fraction of a millimetre. This all

happens inside the machine, just like the soldering process

that is directly attached to it.

The next step of the assembly line sees a number of

people with incredibly fine motor skills assembling the

Through-Hole Technology (THT) parts. These are larger

parts set onto their places on the circuit board by hand –

“larger” being a very relative term in this context. Then the

circuit boards run through a soldering machine again. By

the way, the exhaust thermal energy produced during the

automatic soldering is recovered in order to save energy.

SINCE 1977, RESOL GERMANY HAS BEEN A SUCCESSFUL BRAND MANUFACTURER IN THE FIELD OF SOLAR

THERMAL AND HEATING CONTROL TECHNOLOGY. MAT BRIGGS TOOK A TRIP TO THEIR HEADQUARTERS TO SEE

WHAT GOES ON BEHIND THE SCENES.

SOLAR FIX