4 0

PLUMBING CONNECTION

SUMMER 2015

WHAT NEEDS TO BE AMENDED?

The Standard AS/NZS 3500 parts 1 and 4 need amending

to meet current contemporary practices to include or

reference press-fit as a valid and accepted method of

installing pipework, specifically stainless steel. Press-fit is

already an accepted method of jointing in AS 3688 and has

been for over 10 years. The two standards just need to be

linked.

Standards Australia currently view this matter as a

technical change – and not a simple correction amendment

– as proposed by the industry. Until the Standard is

amended to include the accepted practice of press-fit

connections, these products need to be approved using

‘alternative solutions’.

The following is the proposed amendment the industry

put forward to Standards Australia that rectifies the lacking

acknowledgment of press-fit as an acceptable method of

jointing:

2.4.2 Metallic pipes and fittings

Metallic pipes and fittings shall comply with the following:

a) Fittings used in conjunction with Stainless steel (SS) shall be

either copper alloy compression type and be dezincification

resistant (DR) or SS capillary type manufactured from grade

304 or 316 complying with ASTM A268/268M

or mechanical

jointing end connectors complying with AS 3688.

4.4.9 Jointing of stainless steel pipe and fittings

4.3.8.2

Jointing of pipes larger than DN 25

Joints in stainless steel piping larger than DN 25 shall be either–

a) Butt welded using a tungsten inert gas (TOG) argon arc

method and–

(i) have a gap not greater than 0.5 mm between the

abutting pipe ends to be joined;

(ii) have inserted a back-up ring 6 mm long, made from

the parent, to straddle the joint of pipes with a wall

thickness less than 1.2 mm;

(iii) use a low carbon stainless steel type filler rod not

greater than 2 mm in diameter; and

(iv) be tack-welded in not less than four spots around the

circumference, prior to welding the entire joint; or

b) have flagged joints, fabricated by rolling or welding to the

pipe, a stub flange of the same wall thickness as the pipe,

having a diameter conforming to dimension ‘F’ in AS 2129 or

AS/NZ2 4331, with mild steel backup flange complying with

AS 2129 or AS/NZS 4331 fitted, and a gasket not less than 3

mm thick inserted

; or

c) mechanical jointing end connectors complying with AS

3688.

ALTERNATIVE SOLUTIONS

PROPOSED AMENDMENT TO AS/NZS 3500.4, SECTION 2:

PROPOSED AMENDMENT TO AS/NZS 3500.4, SECTION 4:

This is not an official document of Standards Australia.

This is not an official document of Standards Australia.

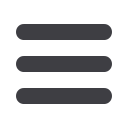

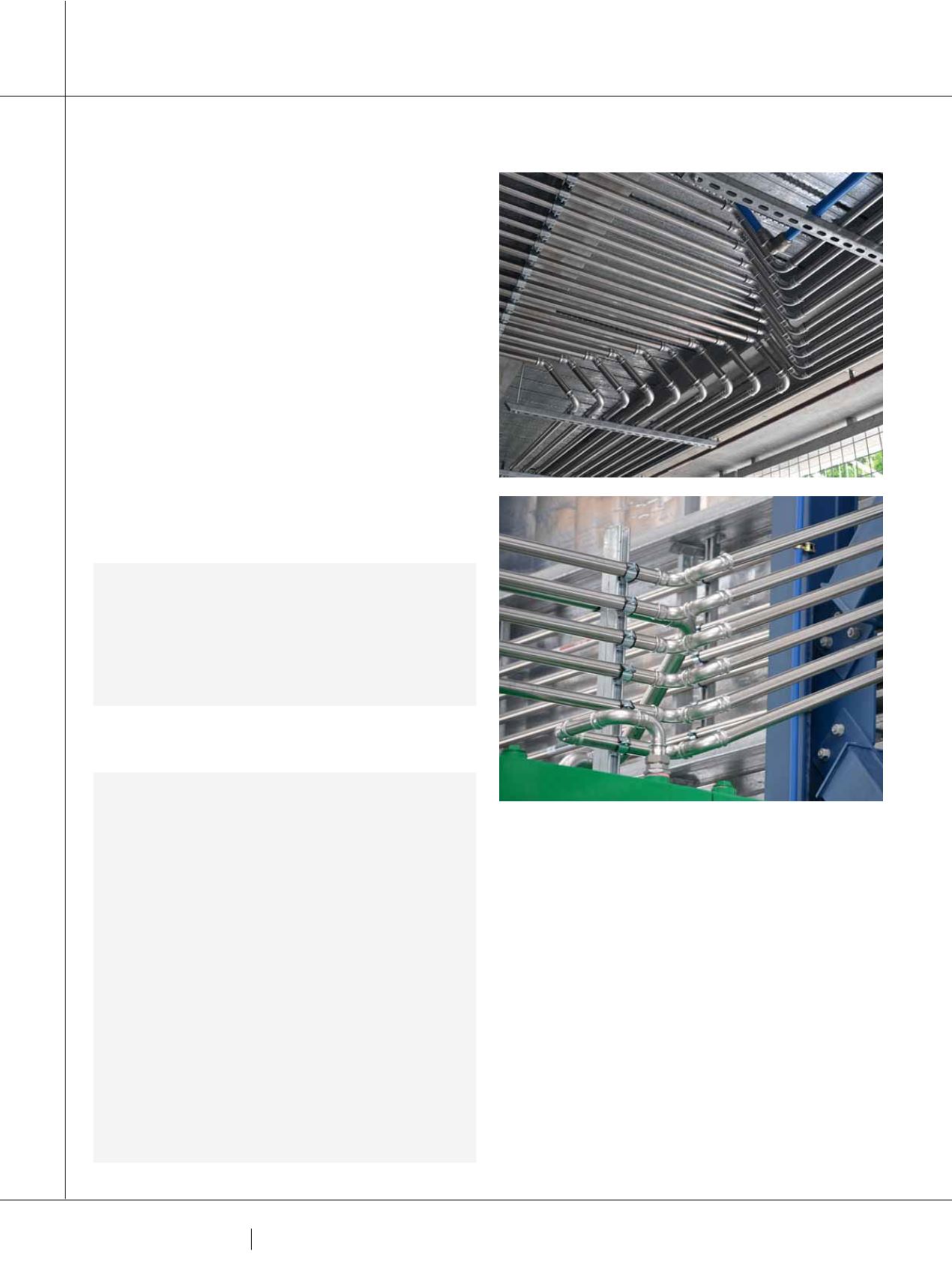

Stainless steel crimp fittings have been used to great effect

for over 50 years, yet Standards don’t cover the material.

WHAT YOU NEED TO DO?

Aside from the fact that the wheels of progress move

slowly across the plumbing sector, there is a very real threat

to your business if you don’t apply for an alternate solution

with your local regulator to cover the past/continued use of

these stainless steel press-fit connections.

It’s rather ironic that at a time when government at all

levels say they are committed to reducing red tape; again

more complexity is upon small business to comply with

practices already approved and installed for years.

Given this issue was still being worked through by a

number of parties as we went to press with this edition

of

Plumbing Connection

, the current solution for both

specifiers and installers is not clear. We’ll be following this

situation closely with updates published on our website

(www.plumbingconnection.com.au)in due course.