PLUMBI

NG CONNECTION SUMMER 2015 39identified in AS 3688 (Water Supply – Metallic fittings and

end connectors) and the lack of connection between the

three documents is the issue.

Due to the nature of developing and amending Standards

over years at a time involving many people, industry

representatives and interests, technology often overtakes

these documents as products, innovation and experience

arise in the profession.

Standards are reviewed at a maximum of 10 year

intervals or sooner if deemed necessary to remain relevant;

from the 1st of May 2016 the NCC is using a 3-year cycle

for producing updates. This becomes problematic when

these same documents are a necessity for specifications,

inspections and complying with law, especially for disputes

and guidance.

In the case of stainless steel press-fit, the current

publications have overlooked this method of joining

despite the testing and historical evidence of stainless

press-fit being used successfully in hundreds of Australian

constructions, WaterMark approvals and becoming the

preferred method of installing pipework over the past 20

years.

WHAT’S THIS MEAN FOR YOU?

Both specifiers and installers need to be aware of the

implications arising from not only stainless press-fit but all

advances in methods and technology – the risk, despite the

success or performance, by not understanding the detailed

and complex processes that go on in the background of this

industry that provide you with a set of Standards and Codes

appropriate for you to work under.

Most of this work is done by a few very dedicated

volunteers, conversing with Standards Australia and the

Australian Building Codes Board. While it may look like a

simple paperwork amendment is required for an oversight

or improvement, such matters take time and lots of

documentation to amend.

After a lot of work within the industry to make

(what most would think is a minor update or amendment)

the appropriate correction in AS/NZS 3500.4:2015,

the extraordinary bureaucratic process in this case

means the required change was not included in in AS/NZS

3500.4:2015 and an amendment will not be published in

time for the 2016 amendment to the Plumbing Code of

Australia.

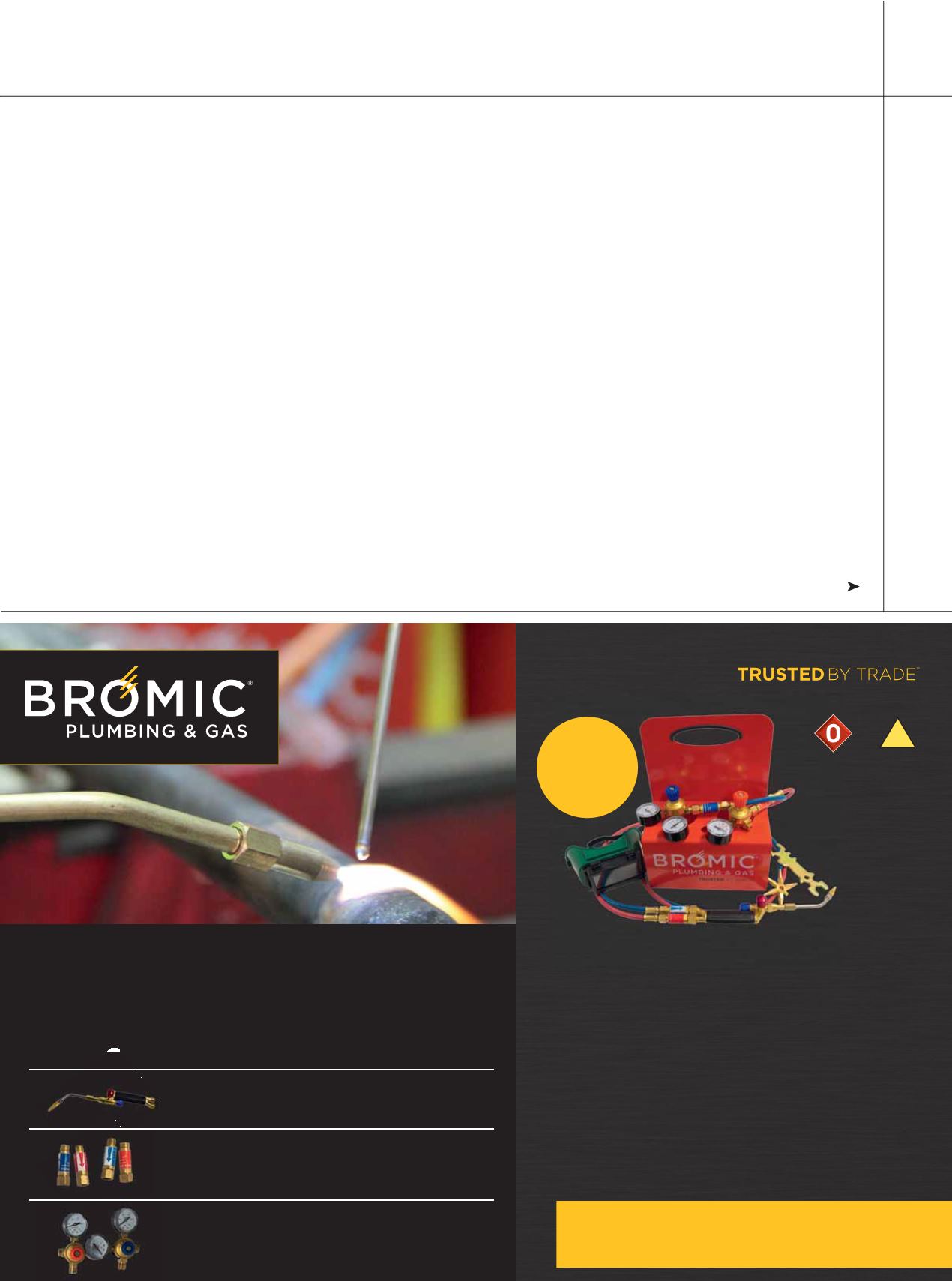

OXYSET

MOBILE BRAZING & WELDING SYSTEM

For more information call

1300 276 642

or visit

WWW. BROMIC .COM.AUMAP//PRO

M

OXYG E N

The Bromic Oxyset is a trade grade mobile brazing

and welding system that utilises disposable oxygen

and Map-Pro cylinders. It is ideal for silver soldering,

brazing, heating and thin metal cutting. The set is

designed for ultimate portability so there is no need

to carry large industrial cylinders or use long gas

hoses to reach your job site. The set also eliminates

the need for expensive cylinder rentals or time

consuming paperwork when participating in rental

programmes.

NEW

Supplied with arrestors for blowpipe and

regulator ends

Easy one handed fuel and oxygen flow

adjustment

Supplied with two gauges on oxygen for flow

and contents and one gauge on the fuel regulator

showing contents