PLUMBING CONNECTION

SUMMER 2015 45

2

3

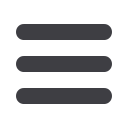

DEZINCIFICATION TEST RECORD

Part Description:

¾” Ball Valve

Direction rod, drawn tube and components

machined from these products

Forgings and castings

Con. cast rod and

components machined

from these products

Direction of grain flow Perpendicular to grain

flow

Thickest Section

Thickest Section

Magnification

50x

50x

50x

50x

Area of exposed surface

50mm

2

No. of Measurements

25

25

25

25

Average Depth of

Dezincification

640 µm

Maximum Depth of

Dezincification

690 µm

Requirement for Average

Depth

300 microns maximum 100 microns maximum 100 microns maximum 100 microns maximum

Type of Dezincification

a & ß’ Attack

Compliance to Product

Standard

*Test completed in accordance with the Australian Standard AS2345 (2006) - See method in Appendix C (75ºC±3 for a duration of 24

hours ±0.5h)

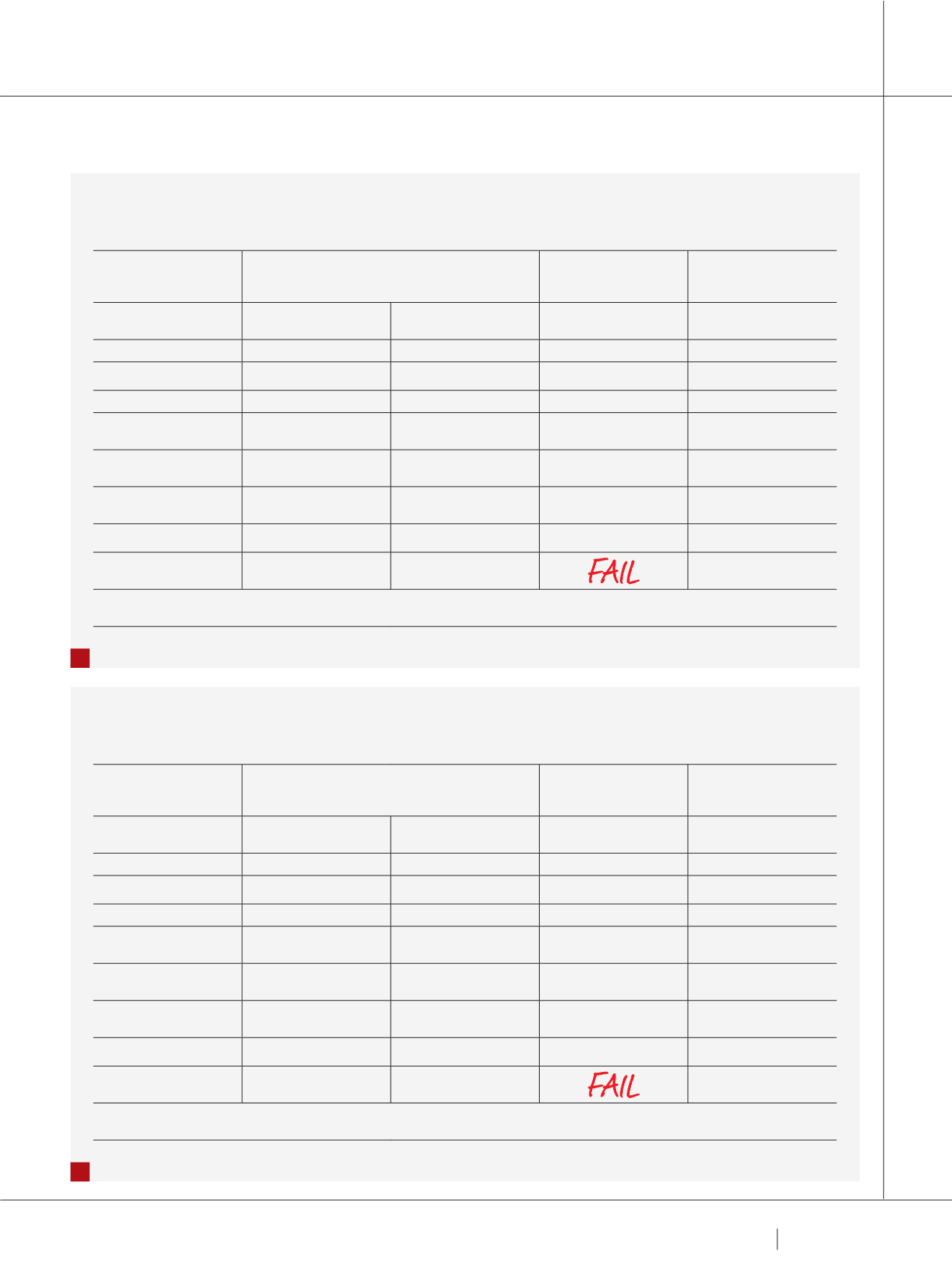

DEZINCIFICATION TEST RECORD

Part Description:

Threaded Socket Hexagon - 15mm

Extruded rod, drawn tube and components

machined from these products

Forgings and castings

Con. cast rod and

components machined

from these products

Direction of grain flow Perpendicular to grain

flow

Thickest Section

Thickest Section

Magnification

50x

50x

50x

50x

Area of exposed surface

140mm

2

No. of Measurements

25

25

25

25

Average Depth of

Dezincification

367 µm

Maximum Depth of

Dezincification

656 µm

Requirement for Average

Depth

300 microns maximum 100 microns maximum 100 microns maximum 100 microns maximum

Type of Dezincification

a & ß’ Attack

Compliance to Product

Standard

*Test completed in accordance with the Australian Standard AS2345 (2006) - See method in Appendix C (75ºC±3 for a duration of 24

hours ±0.5h)