PLUMBING CONNECTION

AUTUMN 2015 79

various appliances in a gas installation work correctly – gas

at the correct pressure and volume, electricity and water.

When the regulator pressure requires adjustment, the

plumber/gasfitter must arrange for the distributor to attend

and establish the correct settings. If the plumber/gasfitter

has to leave the site while waiting for adjustments to be

arranged and carried out, this could mean additional costs

for the consumer.

The left hand does not seem to know what the right hand

is doing. How are plumbers/gasfitters supposed to ensure

that gas pressures at an appliance are safely tested and

adjusted (where the supply pressures are too low)? And who

pays for the process?

You can imagine trying to check every appliance in an

apartment building. Someone has to arrange access to

properties and get the distributor on site at the same time.

Co-ordinating that would be a nightmare, particularly if a

problem meant that supply had been withdrawn.

There has been no reply from ESV since I contacted its

representative in 2012 about these matters.

Additional confusion stems from the fact that any meter

installation after that time may be set al 1.1KPa in lieu of at

least 1.2KPa, and Gas Information Sheet No. 4 (distributed in

October 2013) covers “Allowable leakage rate for standard

installations operating at 1.13kPa”.

The ‘Explanation of terms’ section is quite specific that

the nominal figure for billing is 1.13kPa, and you should not

have anything less at the inlet to any appliance.

Because of pressure drop in a gas fitting line, it is hard to

believe that this would be achievable – unless the fitting line

was only 300mm long.

The term ‘nominal metering pressure’ crept into the

industry several years ago as the figure for billing purposes.

However, the word nominal is not associated with the 1.1kPa

outlet pressure from the gas meter in the Gas Distribution

System Code, so distribution companies have to supply only

that figure.

Unfortunately, it seems that the 1.1kPa outlet pressure

has become the norm, and the lack of gas appliance service

training in Victoria for at least 10 years does not help

matters.

Since natural gas became available, the outlet operating

pressure has been 1.25kPa ± 50Pa, as per the minimum flow

rates in pipe sizing laid down in AS/NZS 5601-2013.

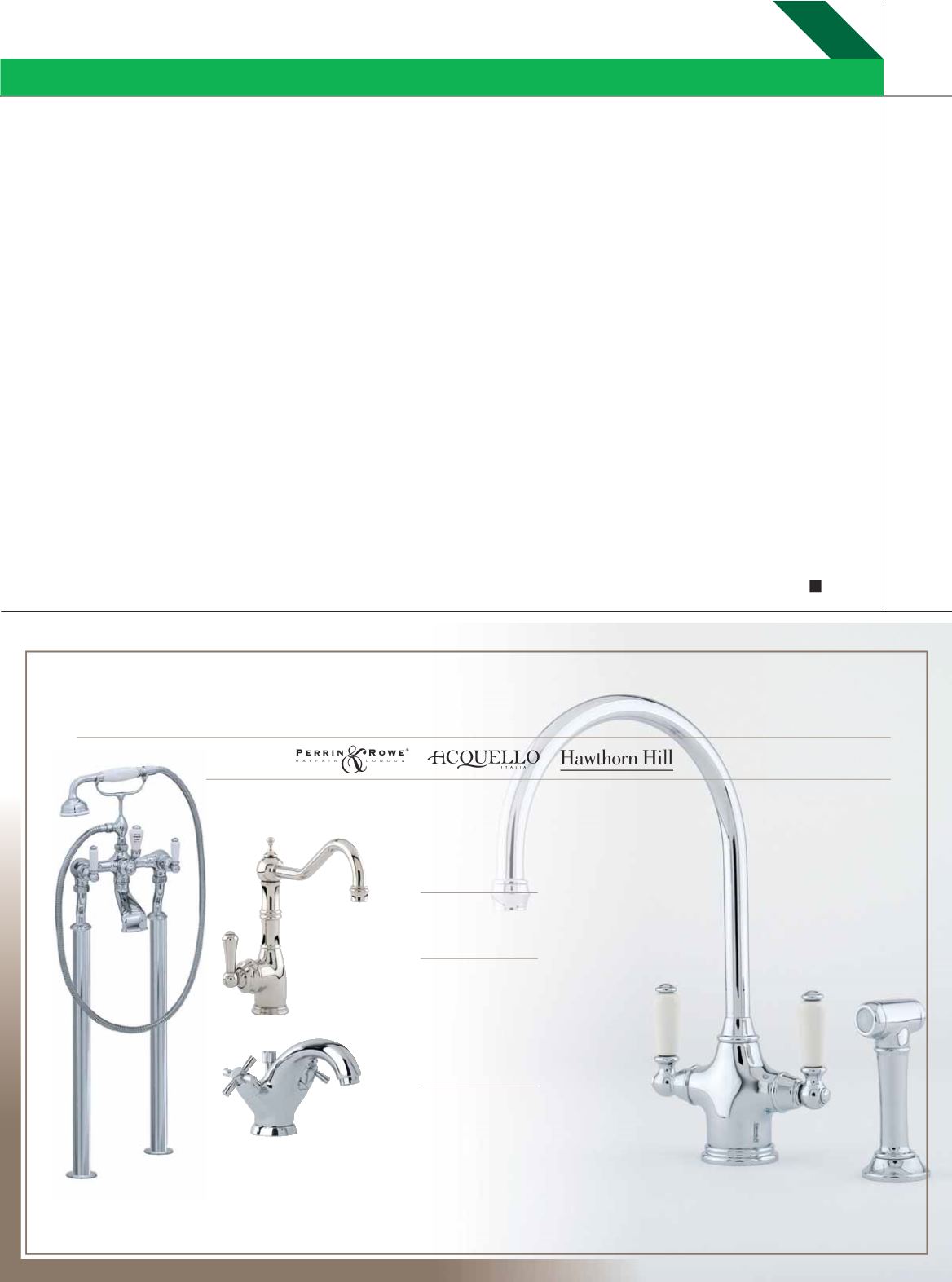

THE ENGLISH TAPWARE COMPANY

/A> PHKE=qL ;>LM DBM<A>G :G= ;:MAKHHF gMMBG@L ?HK RHNK =BL<>KGBG@ <EB>GML

FULL SPECIFICATION &

INSTALLATION GUIDES

AVAILABLE

SPARE PARTS TO

SUPPORT OUR PRODUCTS

PERRIN & ROWE TAPS:

MADE IN UK SPECIALLY

FOR COMPATIBILITY

WITH AUSTRALIAN

PLUMBING

WELS & WATERMARK

CERTIFIED

HGM>FIHK:KR :G= MK:=BMBHG:E LMRE>L BG : K:G@> H? =BLMBG<MBO> gGBLA>L BG<EN=BG@ ;:K> ;K:LL

SYDNEY

) ! ("%! #&"% }

MELBOURNE

) " (' ' # " }

www.englishtapware.com.auNATIONWIDE:

" % ' }

Available throughout Australia from your local REECE store