7 8

PLUMBING CONNECTION

AUTUMN 2015

That leaves the second method. However, before using

a pressure test piece you need to understand that it would

involve disconnecting the fitting line from the gas meter,

removing the test point screw and making any necessary

adjustment of the meter regulator.

Doing this contravenes the Gas Distribution System Code

and would be classed as tampering with the meter. Only

the distribution company or its appointed representative is

allowed to intervene. If an incident occurred, investigation

would determine whether anyone touched the gas meter,

and charges could be laid.

DIVERSITY CONTRADICTION

The gas distribution company’s advice on diversified gas

load is quite concerning when it comes to correct operating

pressures.

Diversity factors are based on not having all appliances on

at the same time.

A simple explanation is that a 200Mj continuous-flow

hot water service in a residence with one bathroom would

operate with full gas flow only at start-up. It would then

modulate to a lower rate.

If the same appliance was servicing three bathrooms, the

potential for simultaneous operation at peak periods would

be greater.

In the old days the typical dwelling had a cooker, storage

hot water service and a space heater with a maximum gas

load of 200Mj.

But the world has changed, and a single continuous-flow

hot water service of 200Mj in full operation would limit

the remaining gas volume from a standard 6m³ domestic

gas meter. In these days of open-plan living there could be

ducted heating consuming 120Mj or 150Mj, and the cooker

might also be on.

One size – and in this case one rule (“therefore gas

meters are sized to provide the anticipated diversified gas

load”) – does not fit all.

The plumber/gasfitter is required by AS/NZS 5601-2013

to size a gas installation to suit the connected gas load.

Moreover, pressure of 1.13kPa must be provided at the inlet

to every control device on every appliance in the installation

when they are all operating.

In fact, the gas meter might be sized to suit a diversified

load at a supply pressure of only 1.1kPa.

Talk about a plumber being under pressure to do the work

safely and effectively!

If the supply pressure is insufficient to serve an

installation, the plumber has no authority to make any

adjustments at the meter assembly.

When it comes to testing a gas installation, there is now

quite a gap between what is practical and what is required to

do the job correctly. But one thing has remained constant:

you must have all the required ‘energies’ to ensure that

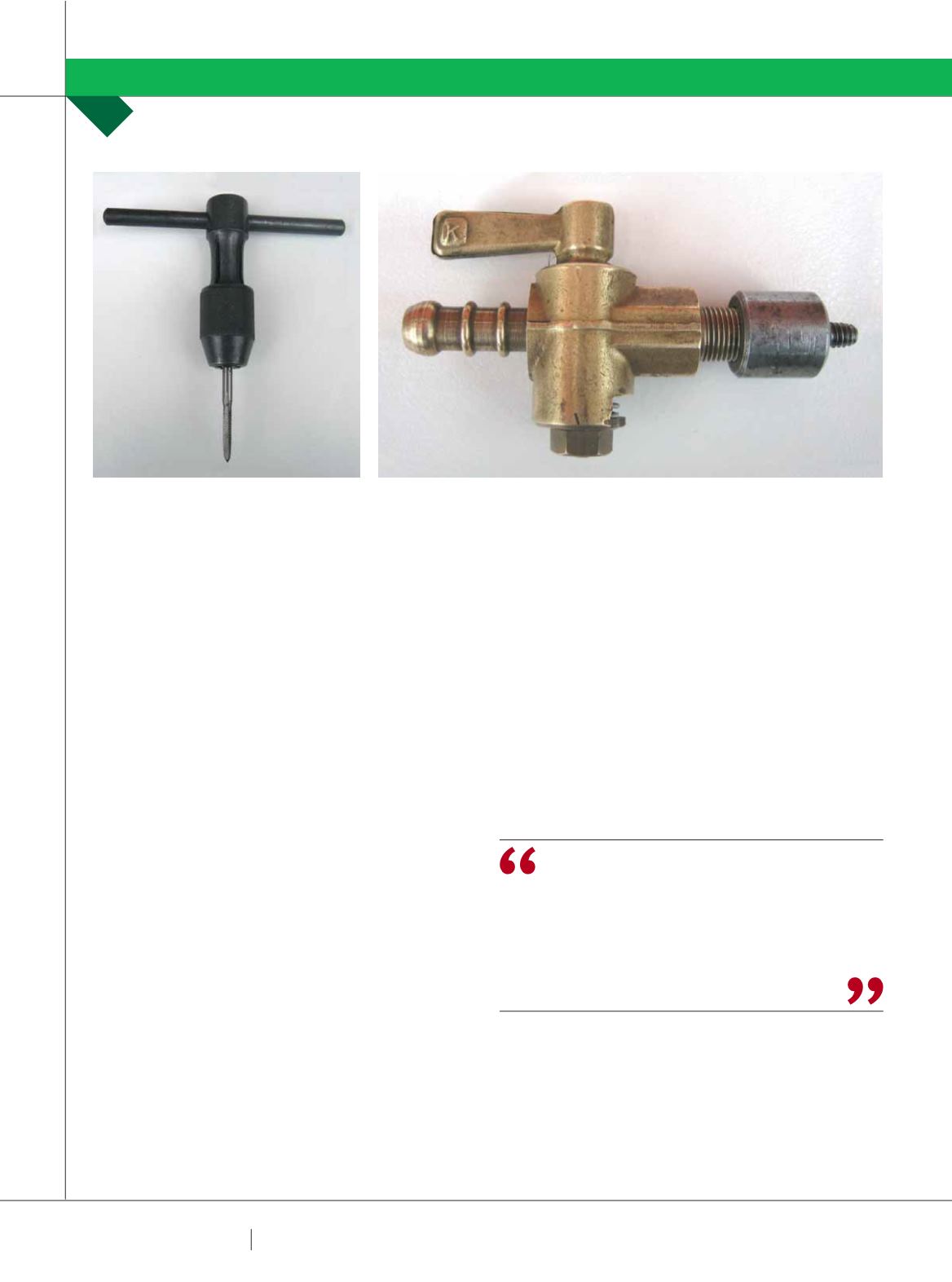

Not all gas meters incorporate a test point at the oitlet of the meter. Many Victorian plumbers were taught to drill and tap

the fitting line at a point close to the meter and insert a gas cock for pressure testing that would be later removed.

GAS MATTERS

ROGER LAMBIE

WHEN IT COMES TO TESTING A GAS

INSTALLATION, THERE IS NOW QUITE

A GAP BETWEEN WHAT IS PRACTICAL

AND WHAT IS REQUIRED TO DO THE

JOB CORRECTLY.