74

PLUMBING CONNECTION

AUTUMN 2015

PLUMBERS UNDER PRESSURE

A

fter 50 years in the plumbing industry I am still

surprised by the lack of understanding when it comes

to gas.

Particular concerns include the servicing of gas

appliances, operating gas pressures and the volume of gas

supplied to an appliance. The situation is made worse by

authorities issuing wrong information.

I served my apprenticeship with a large Melbourne-based

builder, working on multi-storey buildings and large factory

complexes before joining the Gas & Fuel Corporation of

Victoria (G&F) in 1976.

Initially, I was a gas appliance service fitter and foreman/

supervisor in general field applications. Next came six years

with Technical Services, working in association with the G&F

Scientific Services division.

At Technical Services I supervised a team of service fitters

that inspected gas appliances for approval and certification

to Australian Standards, and for G&F appraisal.

Other duties included investigating fires and explosions

for any involvement of gas, and field survey work on

appliances for wear and tear after a number of years’

service. The latter was a form of quality control – identifying

potential problems and suggesting preventive design

features for new appliances.

After ensuring we had a safe working area, the first

things we checked in relation to any gas appliance were the

operating pressure and volume of gas (correct pipe sizing).

If these are not correct, several operational problems can

arise.

G&F field manuals advised that the supply pressure at

the outlet of the gas meter had to be between 1.2kPa and

1.3kPa.

This was to ensure an inlet pressure of I.13kPa at the

appliance control valve. The operating pressure was then

set according to the badge plate of the appliance – in

compliance with approval/certification under the Australian

Standard for that appliance.

THE MINIMUM

Clause 5.2.5 and Table 5.1 of AS/NZ 5601 1:2013 clearly

state that the minimum natural gas operating pressure at

the inlet to an appliance is 1.13kPa.

Note that in a domestic situation where a Type A appliance

is installed, a pressure of 1.13kPa is to be available to the

first appliance control valve device other than a manual

shut off valve. This pressure must also be available to every

appliance in the installation with all of them operating fully

at the same time.

Appendix F of the Standard, “Sizing consumer piping”,

requires the minimum supply pressure from the meter (as

noted in Tables F6, F10 and F23) to be 1.25kPa – as stated

in the G&F field manual.

Without a minimum outlet supply pressure from the gas

meter of 1.2kPa it is impossible to achieve pressure of

1.13kPa at the inlet to a control device.

SYSTEM CODE

The Essential Services Commission (ESC) in Victoria has

released Version 11 of the Gas Distribution System Code,

which came into force on October 13, 2014 (www.esc.vic.

gov.au).

To my bewilderment, this code and versions back to

Version 9 (effective January 2009) require that distribution

companies provide a supply outlet pressure of only 1.1kPa

for meters commonly termed domestic (up to a capacity of

6m³/hr).

CONFLICTING REQUIREMENTS FOR PRESSURE AND VOLUME MAKE IT HARD TO ENSURE SAFE TESTING AND

ADJUSTMENT OF GAS INSTALLATIONS.

ROGER LAMBIE

OUTLINES THE ISSUES.

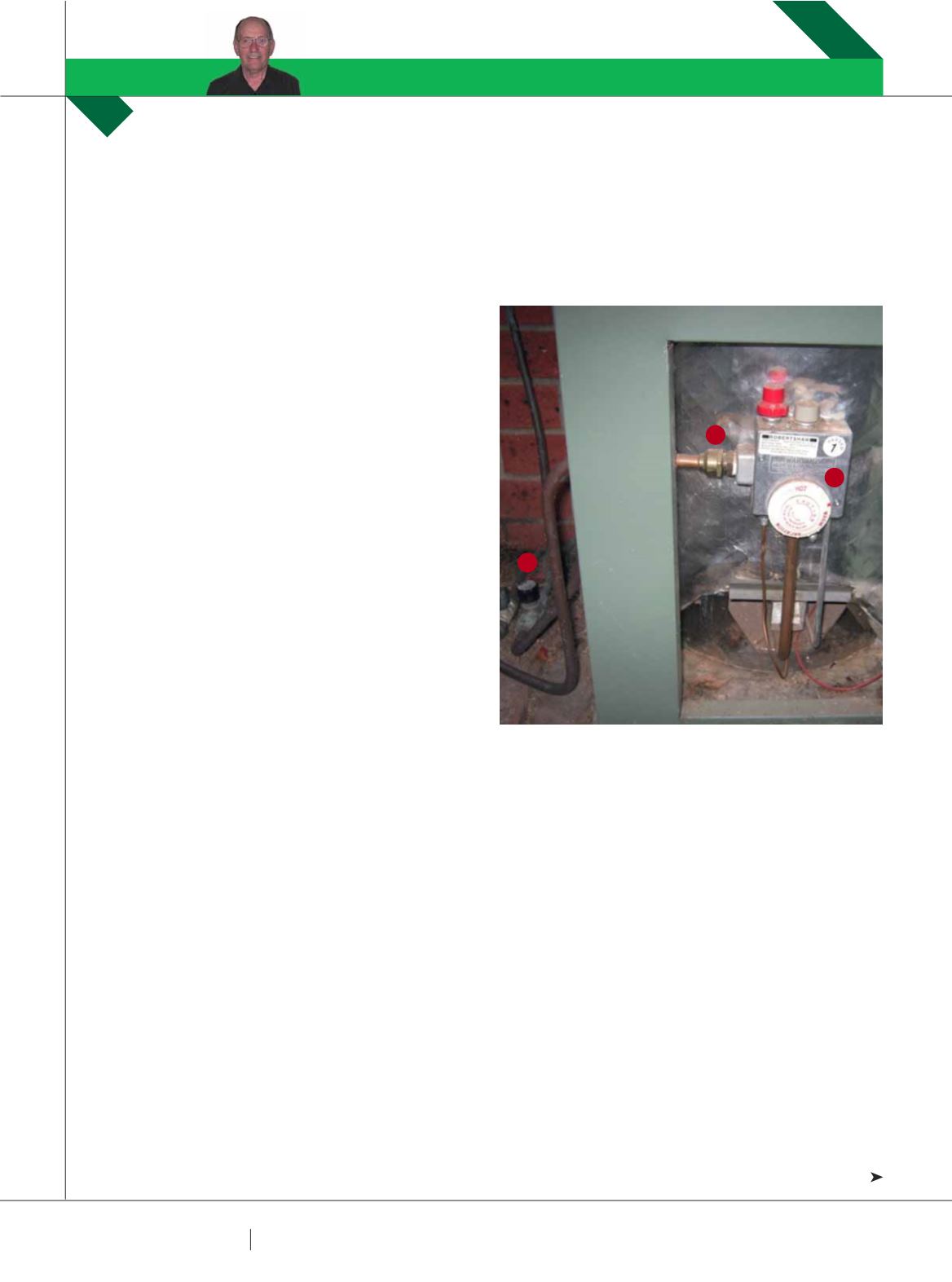

A:

Shut Off Valve.

B:

N.G. Inlet pressure to be no less than

1.13KPa at this point.

C:

Control Device.

GAS MATTERS

ROGER LAMBIE

A

B

C