76

PLUMBING CONNECTION

AUTUMN 2015

The distributor will supply a gas meter capable of

providing the quantity of gas reasonably expected to be

consumed by the customer at a pressure of 1.1kPa (page 33

of Version 9; page 32 of Version 11.).

According to advice from a gas distribution company,

“reasonably expected to be consumed” is interpreted as being

the maximum instantaneous gas load, or diversified gas load

– not the connected gas load. Therefore gas meters should be

sized to provide the anticipated diversified gas load.

All this, even though AS 5601-2004 is referenced in

Schedule 3 of Code 11, even though AS/NZS 5601-2013

was adopted in Victoria in March 2013. The points as noted

below are very similar in AS5601-2004 and AS/NZS 5601-

2013, other than Appendix O.

STANDARD REQUIREMENTS

The following are pertinent aspects of AS/NZS 5601-

2013:

∫ Clause 5.2.5, “Pipe size for consumer piping supplying a

domestic type gas appliance”, states that the operating

gas pressure of 1.13kPa must be available at the

appliance inlet when all gas appliances are operating at

the same time.

∫ Table 5.1 shows the minimum pressure at appliance inlet,

natural gas, to be 1.13kPa.

∫ Clause 6.2.1, “Determination of adequate gas supply”,

includes assessing the maximum gas load and ensuring

the required supply is available before connecting an

additional appliance.

∫ Clause 6.2.2, “Manufacturer’s installation instructions”,

states, in part, that appliances are to be installed

according to the Standard’s requirements and the

manufacturer’s instructions.

∫ Appendix O, “Guidelines for gas appliance commissioning”,

restates that all appliances in the installation must be

operating while performing the pressure check, and the

same procedures must be followed to recommission an

appliance after maintenance and repair.

CONTRADICTION

What does this contradiction of supply pressures mean to

the operation of a gas appliance and the responsibilities of

the plumber/gasfitter?

The plumber/gasfitter is obliged to install and commission

a gas appliance to the requirements of AS/NZS 5601-2013,

and as per Appendix O after maintenance and repair. There

has never been a requirement like the latter in any previous

gas installation Standard.

In any domestic installation under AS/NZS 5601-2013,

with correctly sized lines and the gas pressure set at a

minimum of 1.2kPa from the outlet of the gas meter, a

pressure drop of 70Pa should provide 1.13kPa at the inlet

to the control device. Correct operating pressure should

be achieved at every appliance test point when all are fully

operating.

If the supply pressure is set at 1.1kPa, as per the Gas

Distribution System Code, a pressure drop of 70Pa would

result in only 1.03kPa at the inlet to the control device.

As stated, without a supply pressure of 1.2kPa from the

gas meter you will not get 1.13kPa at the appliance control

device.

Manufacturers would not accept an appliance ‘fault’

if the gas pressure had not been set to its badge plate

specifications or approval/certification requirements.

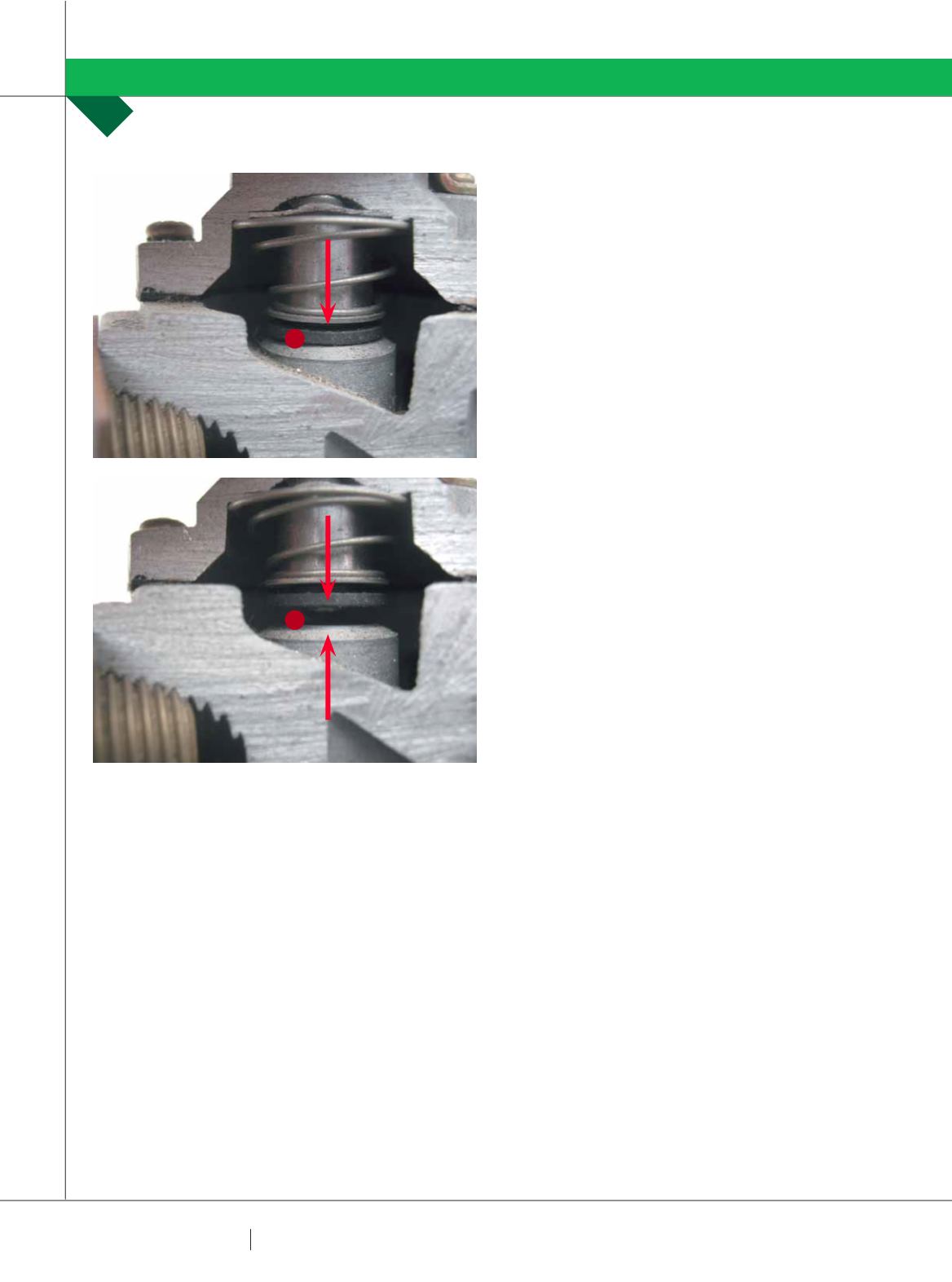

FLOWRESTRICTIONS

Consider the restrictions placed on gas flow through a

control device.

It is not uncommon for gas pressure to drop 80-100Pa

between the control device inlet and outlet.

Some may say this is not crucial. However, AS/NZS 5601-

Restrictions to gas flow within a valve can reduce the outlet

pressure.

D:

Closed

E:

Open

D

E

GAS MATTERS

ROGER LAMBIE