6 2

PLUMBING CONNECTION Winter 2022

IS IT TIME TO LOOK TO LOCALLY

MANUFACTURED PRODUCTS?

T

he COVID-19 pandemic has

certainly left an indelible mark on

the lives of many over the past

two years. In the global supply chain

bubble, the impacts have seen empty

shelves and many sectors scrambling

for supply of critical goods – even at the

very highest level of Government. As

the world begins to look for a way out,

a perfect storm has manifested itself

that is impacting Australian plumbers’

ability to maintain productivity and set

themselves up for an inevitable increase

in activity.

Like many other sectors, the supply

shortage of plumbing products has

been regularly reported due to reduced

access to employees, a global freight

network that sees demand outstripping

supply, exorbitant increases in global

freight prices to unprecedented levels,

and geopolitical tensions potentially

affecting trade globally.

The impact of this over the past

two years has led many to question

Australia’s reliance on global supply,

increasing the focus on maintaining

and building our local manufacturing

capability. Australia has a rich and proud

history of manufacturing, particularly

within the metals sector where our

rich ore deposits have serviced the

manufacturing industry for metal

products for some time.

Manufacturing business like MM

Kembla, who still produce around 87%

of their Kembla copper tube used in

plumbing, HVAC, refrigeration, and

medical gas service lines out of their

Port Kembla, NSW, manufacturing

facility, are becoming a rare breed in

the plumbing products industry. (MM

Kembla is Australia’s only copper tube

manufacturer.) So, is it time for us –

as plumbers, businesses, and proud

Australians – to make a concerted

effort to choose locally manufactured

products and strengthen our local

manufacturing capabilities? The effect

of which will improve the availability and

continuity of supply to plumbers, reduce

the uncertainty of offshore product

availability, sidestep shipment delays

and rising freight costs, and ultimately

reduce our reliance on a global supply

chain over which we have very little

control.

LOWER-PRIORITY AUSTRALIA?

As Governments look to boost

economic activity and lead the way

out of a pandemic, the global demand

for goods is outstripping available

supply. Availability of input materials,

production capacity, and the impact

of fewer available employees due to

isolation periods, infections, and border

closures, have led to increased and

variable lead times on product supply.

The imbalance in supply versus demand

will likely lead to ongoing issues and,

unfortunately, when it comes to global

suppliers, the Australian demand

may not be as critical as the demand

from large countries – leading to a

prioritisation of demand that could lead

to our businesses being further down in

the pecking order.

In the current volatile global marketplace, it may be time to start looking more seriously at sourcing

locally manufactured plumbing products as a more reliable and sustainable strategy, says

John Fennell

from the International Copper Association Australia (ICAA).

COPPER CONNECTION -

JOHN FENNELL

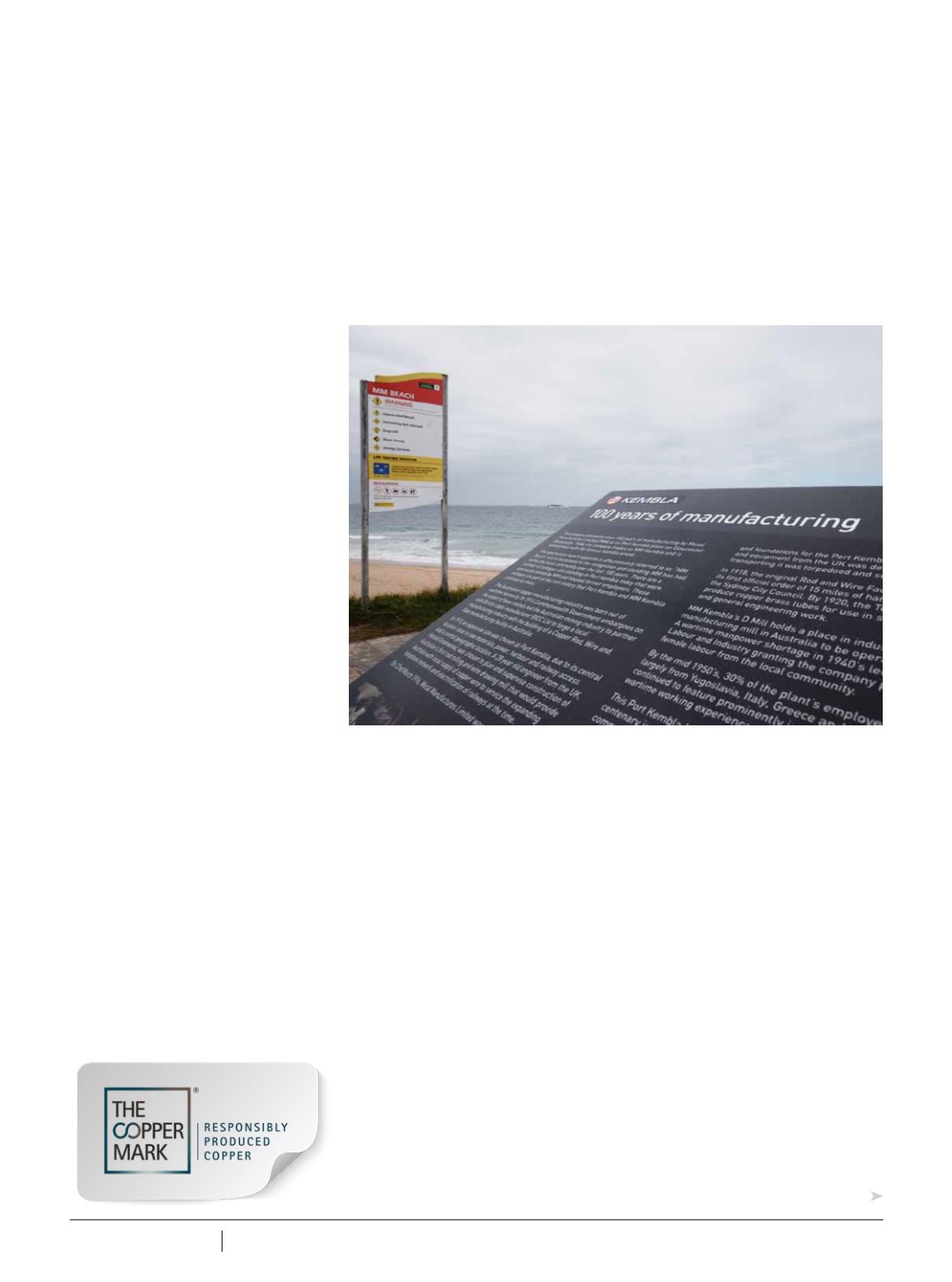

Local copper manufacturing plants like MM Kembla, NSW, are gaining popularity

thanks to the reliability of the company’s supply chains, and, crucially, their

transparent regulatory compliance.