6 4

PLUMBING CONNECTION Winter 2022

However, partnering over the

longer term with local manufacturers

means that businesses can forecast

requirements and ensure continuity

of supply. When there is short supply

of imported product, it is very difficult

to ramp up production quickly to meet

unexpected requirements. Supporting

local manufacturers with a longer-term

commitment means that the product

will be there when customers need it.

CONGESTED FREIGHT NETWORK

You may have noticed the cost of

products increasing over the past 12

months. A big part of that is due to

international shipping rates being at all-

time highs due once again to COVID-19

disruptions. Shortages of containers,

increased demand, congestion at major

shipping hubs, and delays at dispatching

and receiving ports, have all led to

exorbitant increases in the cost to ship

from offshore.

The scramble for available space and

shipping route congestion have also led

to shipment delays and cancellations

impacting almost every sector. All

indications are that this may not

improve for some time, so offshore

sourcing is fraught with risks and high

costs for the foreseeable future.

It is now time to be looking at locally

manufactured options as a longer-term

sourcing strategy for many plumbers

and businesses to mitigate the

associated risks.

GEOPOLITICAL TENSIONS

It’s no secret geopolitical tensions have

the world on a knife edge, and one of the

greatest power plays employed by rival

nations usually centres around trade.

This may be through trade restrictions,

tariffs, restriction of supply or similar

tactics. In any situation this can lead

to uncertainty of supply availability,

with the impact likely to be so fast that

Australian distributors, businesses, and

plumbers would have little time to look

at contingencies – if any are available.

The sourcing of locally manufactured

products reduces some of this risk,

particularly with critical service

products like copper tube. MM Kembla’s

local manufacturing capability means

the nation is self-sufficient in ensuring

ongoing and critical construction,

repairs and refurbishments are not

impeded by geopolitical power plays.

BE RESPONSIBLE

The charter for the commitment to

sourcing sustainable and responsibly

produced products is becoming

increasingly important in the

construction industry. The recently

implemented Copper Mark responsible

production program now provides

the framework to demonstrate that

commitment, which is why MM Kembla

is proud to be a partner of The Copper

Mark.

More recently, BHP’s South Australian

Olympic Dam copper mine site, from

which MM Kembla’s locally produced

copper tube is sourced, has made its

commitment to responsible mining

of copper by being awarded Copper

Mark certification. The commitment to

responsible and sustainable practices

by Australian supply chains is even

more a reason for us to be looking at

supporting these local supply chains.

THE SOLUTION IS ‘HERE’

Whilst many of our manufacturing

industries still rely on the global supply

chain to support their manufacturing

activities, a large degree of their raw

materials, supplies and other resources

are locally sourced. The ongoing supply

chain disruptions associated with global

sourcing strategies are certainly cause

for concern. As demand prioritisation,

trade restrictions and costly global

freight arrangements and delays impact

on the ongoing activities of our plumbers

and construction businesses, there

is no better time than now to throw

support behind locally manufactured

products and maintain our rich history

of Australian manufacturing.

In the plumbing industry, there

haven’t been many that have existed

longer than Australia’s last remaining

copper tube manufacturer, MM Kembla.

With copper tube available right across

the country, and with around 87% of it

being produced in Australia, make sure

the next time you purchase Copper Tube

you ask for the Kembla brand – isn’t it

time we started to look local?

John Fennell has been

the chief executive of

International Copper

Association Australia since

1998.

COPPER CONNECTION -

JOHN FENNELL

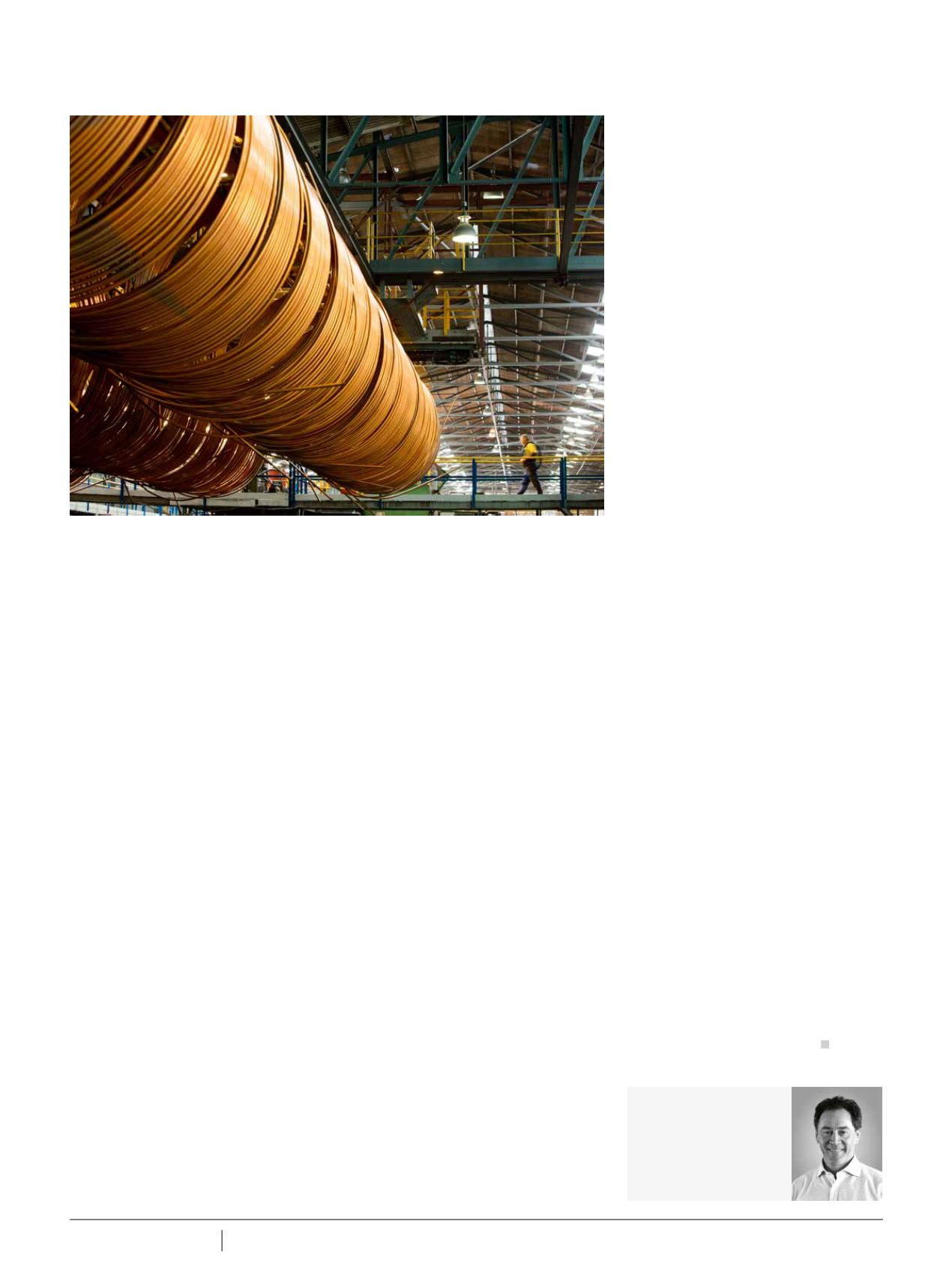

Copper made in Australia provides local jobs while delivering the Quality Assurance

that local markets demand.