2 8

PLUMBING CONNECTION

SUMMER 2016

of four bathroom types/layouts). The target ratio is 100:1

or greater for maximised efficiency and bathrooms should

not exceed 3.0m x 2.3m internally. We have a ‘Designing

for Pods Manual’ on our website, which gives information

to assist with maximising project benefits right from the

design phase,” says Stuart.

Interpod bathrooms are wrapped in heat shrink wrap for

protection when transporting and when exposed to the

elements onsite. Transporting is generally carried out on

semi-trailers or B-doubles, with deliveries to site being at

pre-determined times to fit in with site programming.

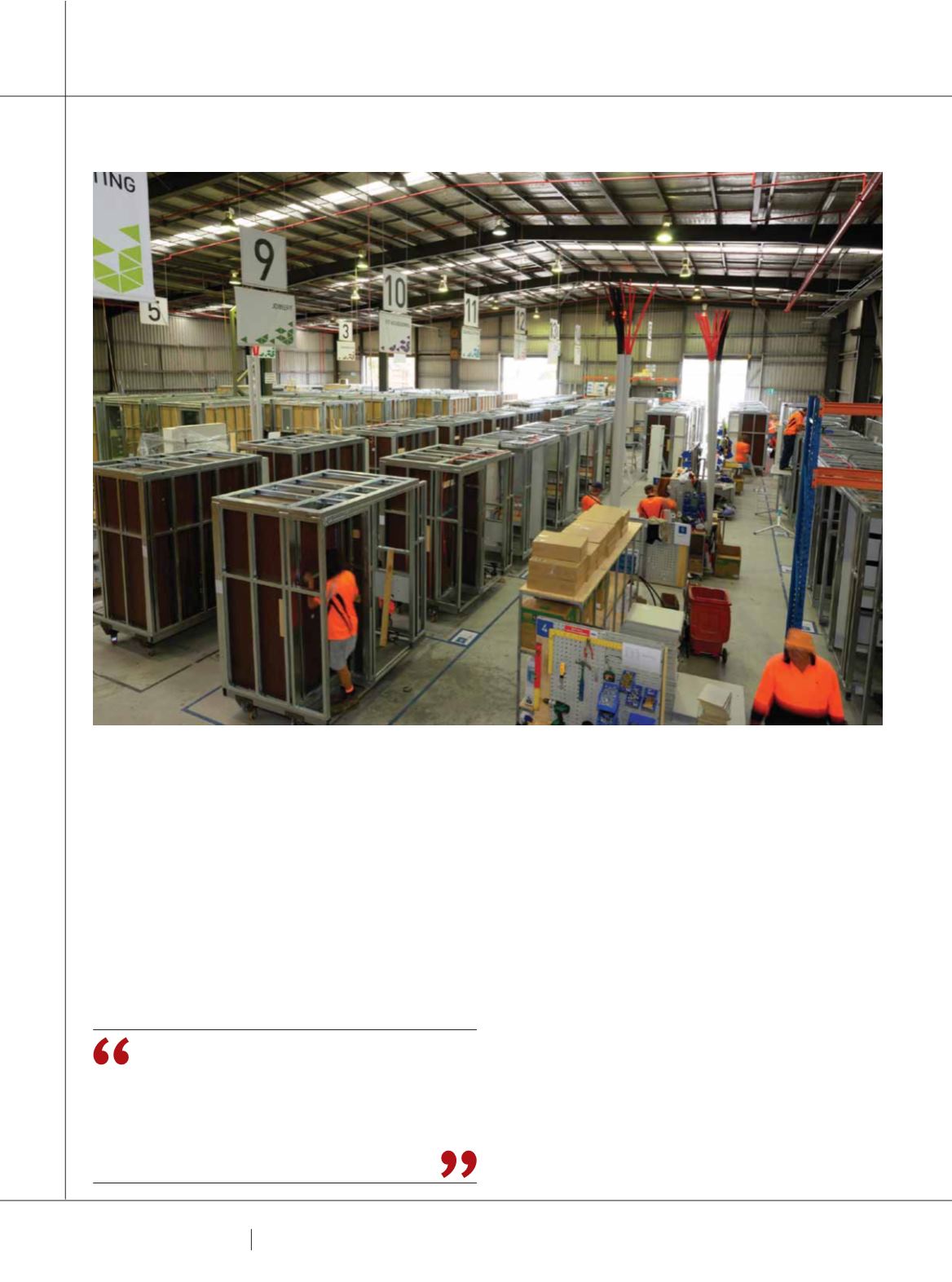

PREFAB CONSTRUCTION

Interpod bathrooms can be used where repetitious design makes offsite manufacturing more efficient.

Pods can then be lifted by crane or unloaded using a

forklift to a materials hoist. When craning, pods are landed

on a cantilever deck, and wheeled across the floor to where

they are to be installed. Installation is typically carried out

by the site plasterers, who install the bathrooms as part of

their initial wall set-out. According to Stuart, specialised

handling equipment is provided by Interpod to ensure that

site time is minimised.

“On a recent project in Brisbane with over 600 bathrooms,

crane cycle time was around three minutes per bathroom.

Interpod’s unique lift system ensures crane time is kept to

a minimum, and can reduce crane time by up to 10 minutes

per bathroom when compared with other systems.”

Stuart breaks down the benefits of using pods as follows:

a. For the builder, Interpod de-risks the project, with

opportunity to provide substantial savings (depending

upon the site specifics) in the following areas:

∫

Time:

if bathrooms are on the critical path, this amount

of time can be taken off the overall project programme.

On a recent project with nearly 1,000 bathrooms, 100

bathrooms were supplied and installed per week.

ON A RECENT PROJECT IN

BRISBANE WITH OVER 600

BATHROOMS, CRANE CYCLE

TIME WAS AROUND THREE

MINUTES PER BATHROOM.