6 6

PLUMBING CONNECTION

SPRING 2015

It is effectively the same as the

dimensionless pump type factor “K”

in the test code standards, except “K”

uses cubic metres per second as the

flow unit.

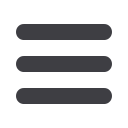

Legendary pump designer, A.J.

Stepanoff created this chart outlining

the various components of pump

inefficiency and showed how these

vary with specific speed (Fig 3).

From Stepanoff’s chart you can see

that casing Hydraulic Losses and Disk

Friction vary significantly with changes

in Specific Speed. In these metric units

the best impeller efficiency is around

Ns of 3000.

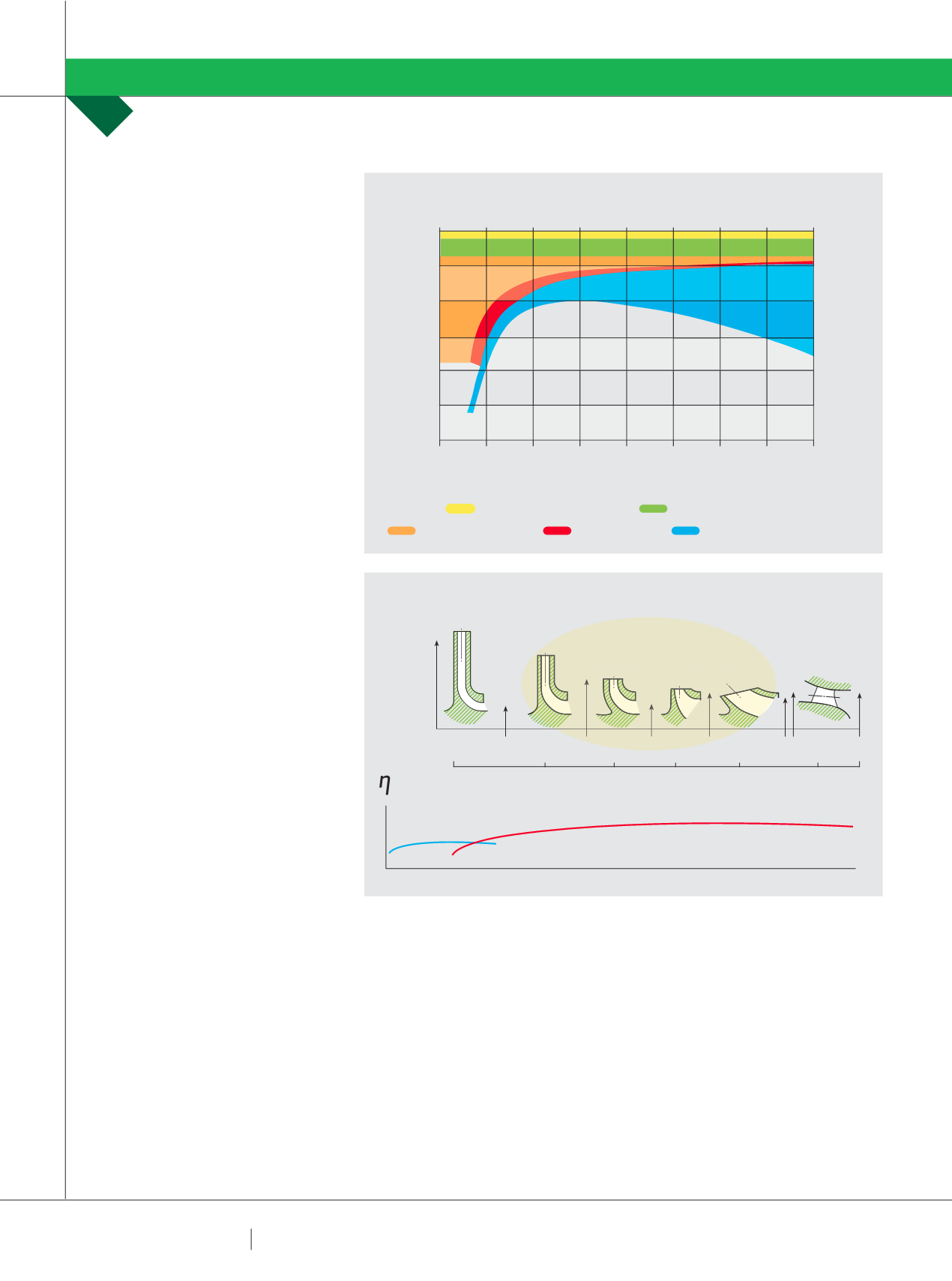

As we saw from Fig 1, low Ns

impellers are larger diameter, narrow

radial flow units. Higher values of Ns

relate to fatter more open shaped

impellers. This makes perfect sense

because the fatter, more open shaped

impellers will have less disk friction

as a percentage of the hydraulic work

being done by the impeller.

The bottom line is that narrow

impellers are less efficient than

“fatter” shaped impellers. See Fig 4.

Bearing the above in mind, it makes

sense to aim for the best shape

impeller when considering what type of

pump to select. If you arbitrarily dictate

the maximum running speed you may

force the pump selection into a low

Ns shape and this will mean a more

expensive and less efficient pump.

Consider the following pump

selections for the same duty but

different speeds (Fig 5):

This is a tangible example of how

specifying a maximum running speed

of 1500 rpm will in this instance cost

the end user dearly; not only in capital

cost but in total cost of ownership.

Now some of you may be grumbling

about reliability, noise and vibration

being also important. Yes they are, but

look at the size of the casing on the

slower running unit, look at how much

heavier its impeller must be and look

at the greater surface area available

to transmit hydraulic noise. In a later

discussion I will look at these aspects

PUMP SCHOOL

RON ASTALL

in more detail and show how the faster

running pump can indeed be more

reliable and can be potentially quieter.

SOWHAT RUNNING SPEED SHOULD

YOU SPECIFY?

You should not specify the running

speed at all!

A great window on this process is the

pump vendor’s range chart. A simple

suggestion is to always start with the

highest speed range chart. If this does

not bear fruit, look at the next speed

down. If there is a sensible selection

at a higher speed it is almost certainly

going to be a more efficient pump than

a lower rpm unit doing the same duty.

To illustrate this, in Fig 6 below I have

overlaid a 2980 rpm range chart (in red

outline) over a 1470rpm range chart for

the same manufacturer. Below the red

outline you can see the regions where a

1470 rpm pump is going to be a better

selection. Inside the red outline, a 2980

selection ought to be better.

Select on the basis of the hydraulic

duty and specify your other primary

requirements directly; such as noise

FIG 3: TYPICAL CENTRIFUGAL PUMP POWER LOSSES

FIG 4: IMPELLER SHAPES AND EMISSIONS

POWER % OF NORMAL INPUT

SPECIFIC SPEED m

3

/h, m, rpm

LOSSES % OF NORMAL INPUT POWER

100

0

95

5

90

10

85

15

80

20

75

25

70

30

0 1000 2000 3000 4000 5000

PARTIAL

EMISSION

EXPECTED BEST EFFICIENCY

SPECIFIC SPEED

FULL EMISSION & AXIAL FLOW

6000 7000 8000

MECHANICAL LOSSES 1%

IMPELLER LOSSES 2.25%

DISK FRICTION LOSS

LEAKAGE LOSS

CASING HYDRAULIC LOSSES

500

15,000

1,000

2,000

3,000

5,000

10,000

SPECIFICSPEED

RADIALTYPE

FRANCISTYPE

PROPELLERTYPE

MIXEDFLOWTYPE

RADIALFLOW

AXIALFLOW

“BEST” SHAPE IMPELLERS