6 4

PLUMBING CONNECTION

SPRING 2015

UNDERSTANDING PUMP CURVES

E

veryone wants more efficient

pumps and pumping systems. In

some industries, the Engineers

and system designers create massive

stumbling blocks by specifying a

maximum allowable pump running

speed.

Putting arbitrary limits on running

speeds will often preclude the best

pump selection.

For clean liquid services, unless

there are difficult suction conditions,

there is no reason to fix a maximum

limit on pump running speed. Energy

efficiency has never been more

important and yet we are still stuck

with these archaic; dare I say ignorant

specifications. Why?

Is it because a slow running pump

is perceived to have a “smoother”

velocity profile, less turbulence and

hence ought to be more efficient? As

we will see later, this perception is

plain wrong.

Is it because a slow running pump

is perceived to have inherently lower

internal wear, better bearing life and

improved reliability? This perception is

demonstrably equally untrue.

Could it be for reasons of noise and

vibration? Yes, these aspects can be

worse with a higher running speed, but

not always. If these are the real issues,

why not simply specify the allowable

noise and vibration limits as direct

requirements?

If you have read this far, you may

be getting a little grumpy because

much of this seems counter intuitive.

Ought not a slow running pump be

less stressed than a high speed

unit? The real question ought to

be; will a slow running pump of the

same performance be less stressed

than a higher speed model doing the

same duty? For the same flow and

same developed head, a slow speed

pump will be larger and will be a

different shape than a higher speed

unit designed for the same hydraulic

duty. We are thus comparing different

shaped pumps.

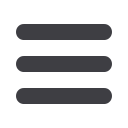

Fig 1 shows a range of impeller

shapes versus a pump design

parameter called “Specific Speed” (Ns).

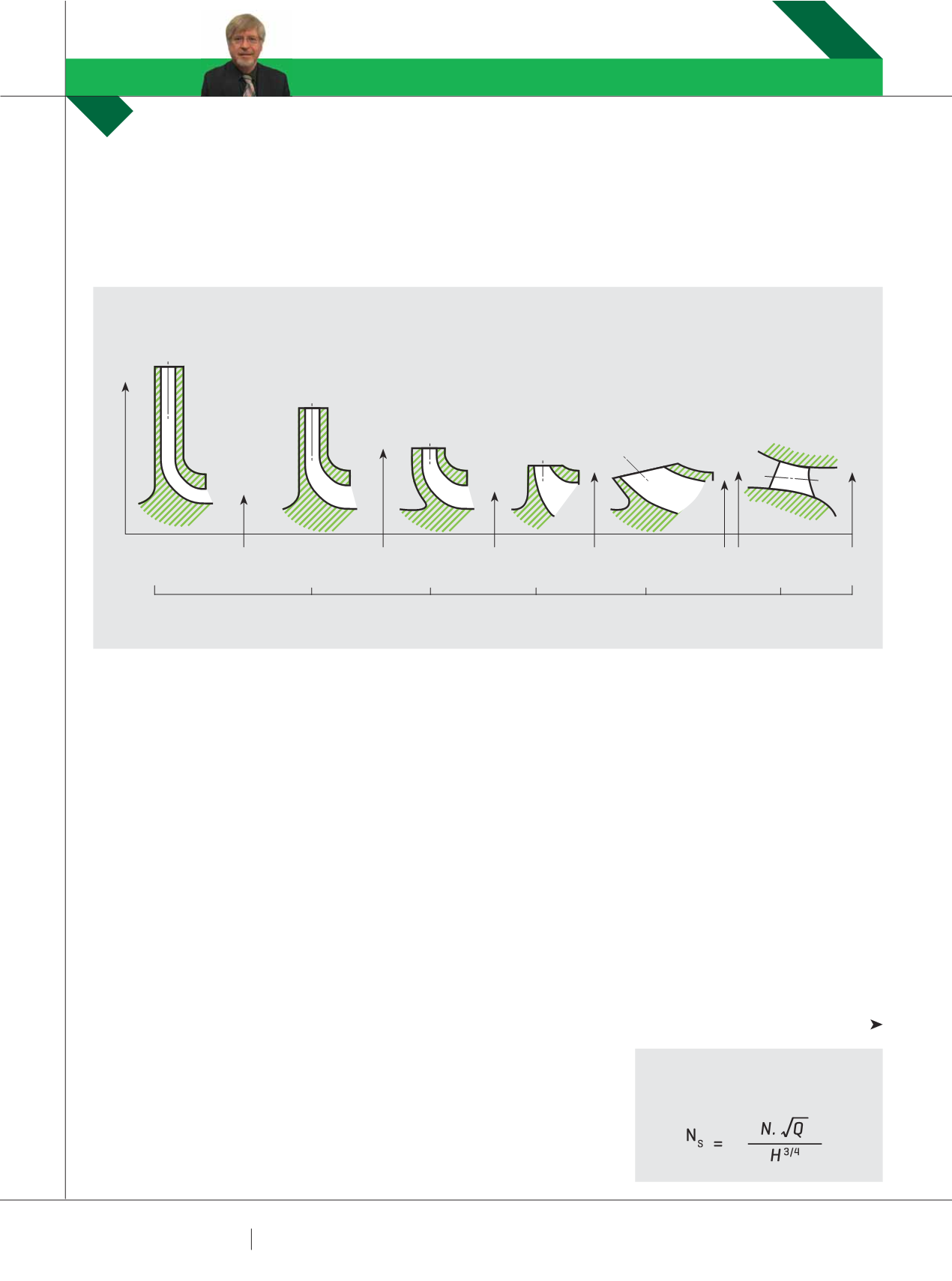

The formula for Ns is shown in Fig 2.

Ns is primarily a shape factor and

this parameter is extremely useful

as an aid to understanding why some

pumps are more efficient than others.

Here it is. Specific Speed (Ns) is a

simple formula involving the RPM,

Pump Flowrate at Best Efficiency Point

(BEP) and Head per stage at BEP.

In Australia it is most common to

use metric units of cubic metres per

hour, metres and rpm; however; when

comparing pump design data it is

important to ensure that you are using

the correct units.

RON ASTALL

ANSWERS THE QUESTION: ARE YOUR PUMPS RUNNING TOO SLOWLY?

PUMP SCHOOL

RON ASTALL

FIG 1: PUMP IMPELLER SHAPES

FIG 2: SPECIFIC SPEED

FORMULA:

HEAD (PER STAGE)

FLOW RATE

RPM

500

15,000

1,000

2,000

3,000

5,000

10,000

SPECIFIC SPEED

RADIAL TYPE

FRANCIS TYPE

PROPELLER TYPE

MIXED FLOW TYPE

RADIAL FLOW

AXIAL FLOW