5 4

PLUMBING CONNECTION

WINTER 2016

pilot configurations. Bi level control valves offer more

reliability in this application due to the fact they are only

either in the open or closed position and aren’t continuously

working when low flow demand times are experienced. The

valves close at pre-set high level position and open once

the low position is reached. The altitude pilot or bi level

float pilot can be installed external to the tank which would

negate the need to enter the tank. They guarantee a high

turnover of water in the tank thus keeping water supply

refreshed.

Where always-full type reservoirs are required to keep

pressures to maximum, modulating altitude or horizontal

pilot controls are the best options. This type of valve and

pilot combination are more commonly used on fire tank

applications. Using a TFV with altitude pilot control will

negate the use of the pilot and make for easier installation

and future maintenance.

VALVE CONTROL

RUSS DUNNE

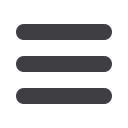

IMAGE 1:

Typical bi level install with external float pilot.

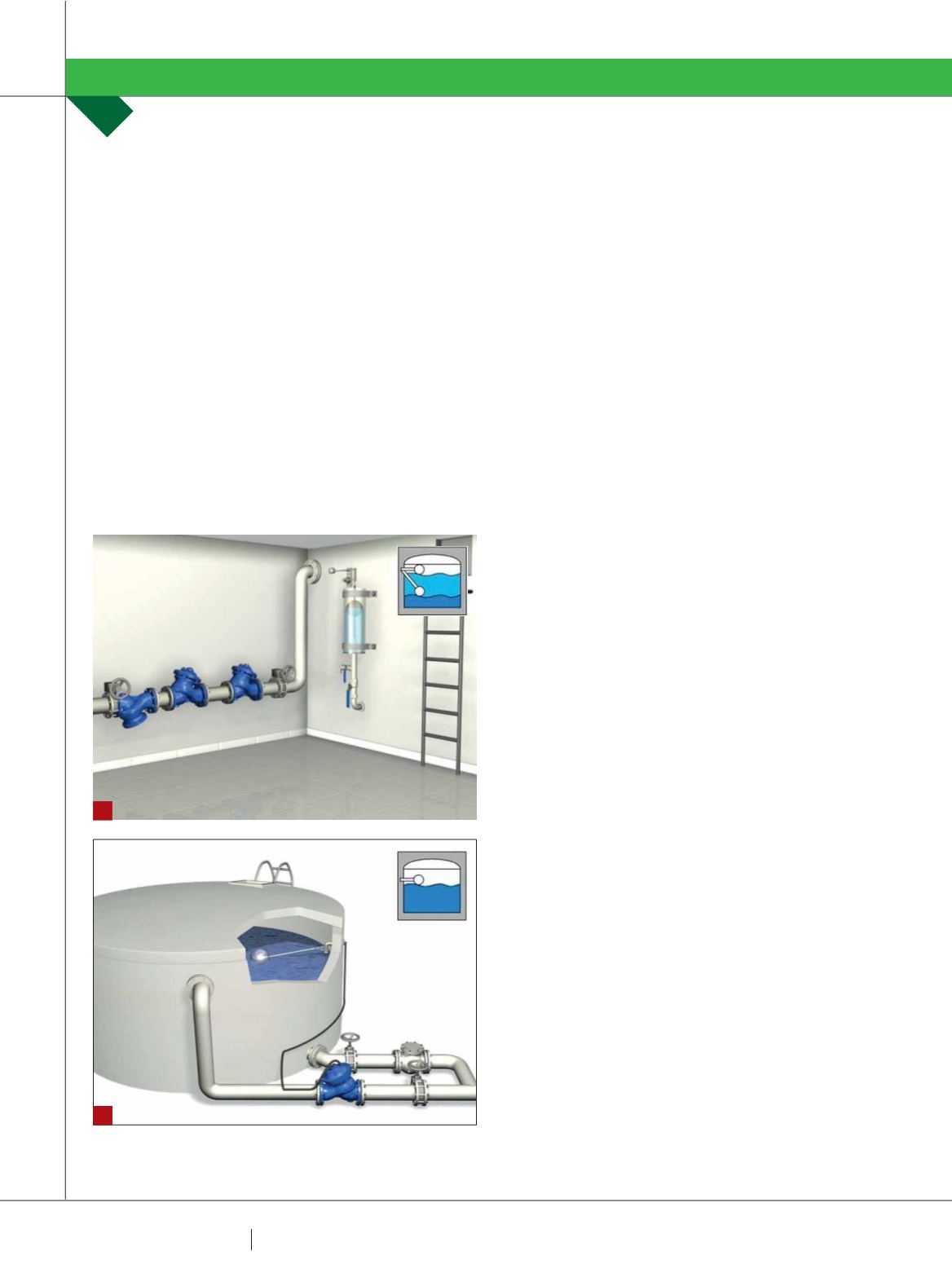

IMAGE 2:

Typical modulating level control valve with internal

mounted float pilot.

FIRE WATER TANKS

Generally fire tanks will always remain in a full capacity

state so as to provide water in the event of a fire. Modulating

pilot or altitude control valves are used in these instances as

any reduction in the water level will almost immediately be

refilled. The issue for some states of Australia is evaporation

of the water level which may cause the valves to modulate

open for very small flows and long term this is not healthy

for the valve. Again, cavitations may occur at low flows,

reducing the life span of the valve.

The common thread in overcoming the evaporation issue

is to use a small 20/25mm modulating servo type float

valve to maintain a full tank. The theory is that the small

float valves will allow the evaporation capacity to be met

without the larger needing to be open. The trouble with this

option is that the larger control valve pilot is permanently

drowned and a small failure of this modulating pilot can

result in the loss of water to the overflow. Without close

monitoring of the tank it may go unnoticed and result in

excess water usage or failure of the larger valve due to low

flow cavitations.

Consideration should be given to using bi level type

valves as used on domestic feed tanks due to the fact

that minimum top water levels can have a minimum level

differential of 150mm. Altitude valves have a minimum level

differential of 300mm-1m with the latter being too much of

a gap between top water when the valve opens.

COMBINED FIRE/DOMESTIC WATER TANKS

Combined tanks have a maximum water level

within the tank that needs to be retained in case of fire

and volume of water above this for domestic feed water.

Using bi level control in this application is ideal as it allows

control of the domestic feed water to be turned regularly

while maintaining a maximum fire level water capacity.

Again, installing the float assembly external to the tank

prevents future maintenance issues and allows easy

access to both pilot and valve during install commissioning.

OH&S issues are averted as no one is required to enter

the tank.

To correctly select the type of level control valve required

there are a few simple questions that should be answered

to allow correct selection of valves. Getting this right at the

start will overcome the many issues and extra associated

cost with rectifying to the correct valve.

∫ Flow required or expected flows

∫ Incoming pressure from either town’s main or pumped

pressure (pressure to the incoming side of the valve)

∫ Valve location

∫ Type of valves V application i.e.

– Domestic feed tank

– Fire water reservoir

– Combined fire/domestic water tanks

1

2