5 2

PLUMBING CONNECTION

WINTER 2016

TANK FILLING VALVES IN BUILDING

RESERVOIR APPLICATIONS

F

or too long most installers see the standard servo

type level control valve (modulating horizontal float

style) as the answer to all level control installations.

While these types of valve do serve a purpose, they are

simply limited to an always full tank filling situation where

incoming pressures are low and head loss across the valve

is minimal.

In this article we’ll address tank filling valves that are

known as self-acting hydraulically actuated diaphragm

control valves and direct acting mechanical valves. These

valves require only the pressure of the incoming supply

pressure to control water levels and are not reliant on

external controls to operate.

FLOWS

It’s important to understand the requirements of water

authorities’ minimum pressures offerings as this sometimes

dictates the size of the valve that can be used. Size a valve

too small and you may run the risk of not being able to

meet the flow demand when pressures are at their lowest.

A good knowledge of the pressures to be experienced will

help the valve manufacturer size the correct valve. Fire and

domestic water supply requirements often differ between

states and as always codes for both fire domestic water

applications should be followed.

PRESSURES

Taking the above into consideration, it is always right

to know the incoming pressures to be experienced during

normal operations of the Tank Filling Valves (TFV). Most

incoming pressures are reasonably high and installing valves

directly at or near the outlets of pipework to the tank may

cause the valve to experience severe cavitations due to high

change in pressure (∆P) across the valve. Cavitations can

be caused by either high or low flows with high ∆P. In this

instance it would be advisable to install a pressure reduction

valve upstream of the TFV so as to negate the effect it has

on the TFV. The pressure reduction valve will impede on the

flow requirements as they modulate to accommodate flows

regardless of differing upstream pressure fluctuations.

VALVE LOCATIONS

While most servo type direct acting float valves get

installed at the outlet of the pipework and generally in

the tank, modulating self-acting hydraulically actuated

diaphragm control valves should be installed external to the

tank with control pilots either within or external to the tank.

Preferably the valves should be installed in the horizontal

upright position at the base of the tank’s inlet pipework.

They can operate in the vertical ascending position as well.

Locating the TFV and control piloting external to the tanks

would be the best option where possible as this will prevent

future issues in regards to servicing and replacement. If

the control valve and piloting are external to the tank this

will also negate the safety requirements of entering tanks

during and post construction.

VALVES SELECTION V APPLICATION

DOMESTIC FEED RESERVOIRS

When considering valves for this application, there are two

common types of control: valves with bi level or modulating

level control. They can either be in altitude pilot or float

WHILE MANY BELIEVE THAT SIMPLY INSTALLING A LEVEL CONTROL VALVE IN A RESERVOIR BUILDING APPLICATION

WOULD BE A SIMPLE PROCESS, TOO OFTEN THIS IS NOT THE CASE. IN HIS NEW COLUMN,

RUSS DUNNE

OF BERMAD

WATER TECHNOLOGIES EXPLAINS WHAT ELSE THERE IS TO KNOW.

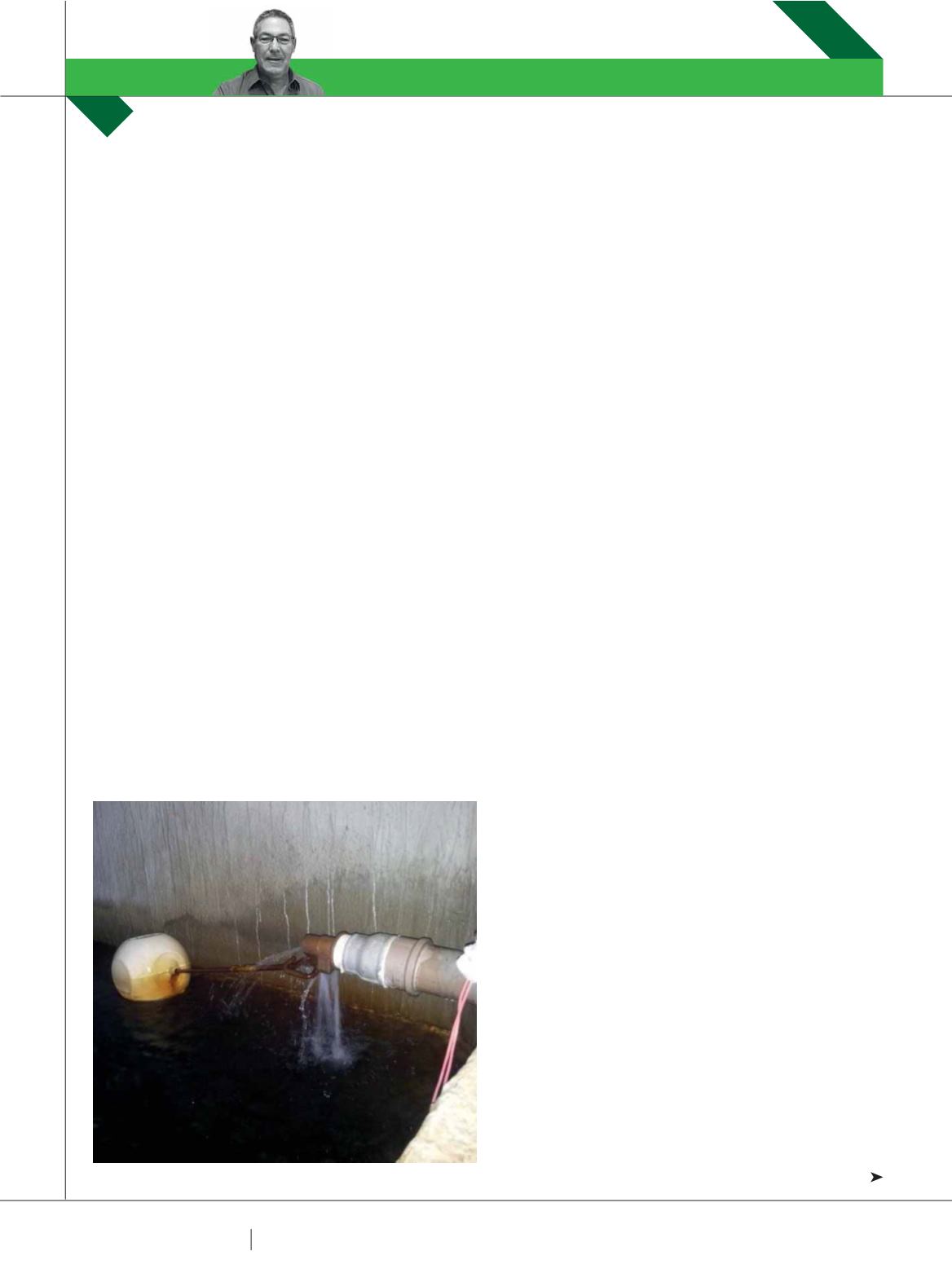

The above is a typical installation of mechanical float valves.

VALVE CONTROL

RUSS DUNNE