6 2

PLUMBING CONNECTION

AUTUMN 2015

Single stage pumps with hydraulically unbalanced

impellers will experience higher axial thrusts at low flow, as

will multistage pumps without a balancing device; such as

vertical turbine pumps. Hydraulically balanced designs are

theoretically unaffected.

A less predictable aspect, however, is the problem of axial

shuttling that may sometimes occurs due to recirculation

and flow reversals at low flow. Significant axial shuttling will

not only load up the thrust bearings but will also play havoc

with mechanical seal reliability.

RADIAL THRUST – VOLUTE CASINGS

All the flow path geometries in the pump are

designed for BEP velocities. When a pump is operated

away from BEP, the velocity profile is distorted. At low flow,

the impeller is still trying to push out the liquid at design

velocities but as flow progresses around the volute the

velocity profile must slow down to match the outlet flow.

This results in a higher pressure distribution towards the

exit and hence a higher average pressure in this region

of the casing. This acts on the periphery of the impeller and

creates a radial (side) thrust which is, of course transmitted

via the impeller to the shaft and bearings. See Fig 4.

This side loading on the shaft can be quite severe and

has even been known to lead to shaft breakage in lighter

construction pumps as well as considerable reduced bearing

life. Some “Heavy Duty” pump standards such as API 610

specify minimum bearing life to be calculated at zero flow as

well as at rated flow for this reason.

Pumps with double or staggered volutes are often used

to minimise this effect. A double volute pump casing can

reduce this radial loading to around a quarter of that of an

equivalent single volute.

If low flow operation is expected to be a regular feature of

a particular application, it would be wise to request bearing

life calculations at the low flow duty and where practical,

seek out double volute construction along with a heavy duty

shaft and bearing arrangements.

TEMPERATURE RISE

An 80% efficient pump turns 80% of the input shaft power

into useful flow and pressure. What happens to the other

20%? This 20% energy loss basically goes into heating the

pumped liquid. Indeed, there are metering devices available

that accurately measure the fluid temperature difference

between the pump inlet and outlet to determine pump

efficiency from the temperature rise.

Efficiency reduces dramatically at low flow. Consider a ten

kilowatt pump operating with an efficiency of 30%. In reality,

this is a three kilowatt pump and a seven kilowatt heater.

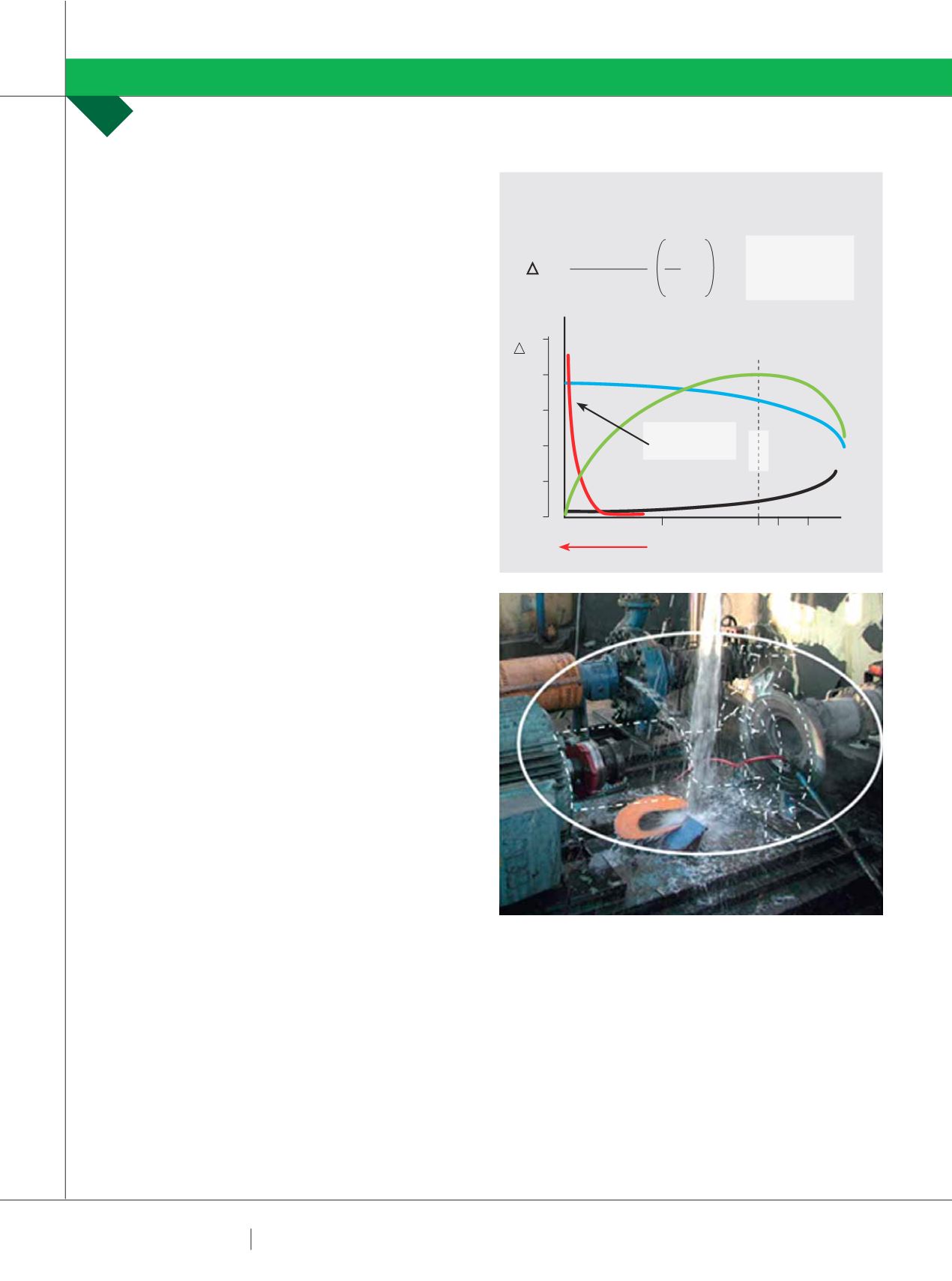

The formula for calculating temperature rise across a pump

is very simple. See Fig 5.

If you are on the ball, you will have spotted that “n” in the

Delta T formula is pump efficiency which is of course zero

at zero flow. If you are even a passable mathematician, you

will also have worked out that one divided by zero is equal to

infinity. Yes, the theoretical temperature rise in a pump at

zero flow is infinite!

Yes, this is scary and yes the reality is that pumps get very

hot very quickly at zero flow. See Fig 6.

OK, in a single stage pump it is unlikely that you will

PUMP SCHOOL

RON ASTALL

FIG 5: LOW FLOW TEMPERATURE RISE

HEAD

EFFICIENCY

LOW FLOW RATES

POWER

BEP

TEMPERATURE

RISE CURVE

50%

H

100 110 125

Q%

T

T =

g X H

1000 X C

P

- 1

1

n

T (˚K)

g = 9.8 M/s2

H (m)

Cp (kJ/kgK)

(Cp FOR WATER = 4.18)

N = DECIMAL EFFICIENCY

FIG 6

THE EXPLODING PUMP:

This process water pump was

operating with both suction and outlet valves closed. The

water contained within the pump casing superheated and

the high pressure steam caused the pump to explode.