6 0

PLUMBING CONNECTION

AUTUMN 2015

INTERNAL TURBULENCE

The Best Efficiency Point (BEP) is where a centrifugal

pump works best. This is the flow the hydraulic passages in

pumps were designed for, where the fluid velocities most

closely match the geometries of the impeller and the casing,

where the pressure distribution around the impeller(s) is

symmetrical and where hydraulic passage entry and exit are

the smoothest.

Operating away from BEP moves the velocity profiles away

from this ideal, leading to compromised flow, inevitable

turbulence and recirculation. An excellent analogy is a

sailboat; with the sail being equivalent to the vanes of the

impeller. At BEP the sail is correctly angled to the wind. Away

from BEP the sail will flap or flutter. The further away from

BEP, the worse it gets.

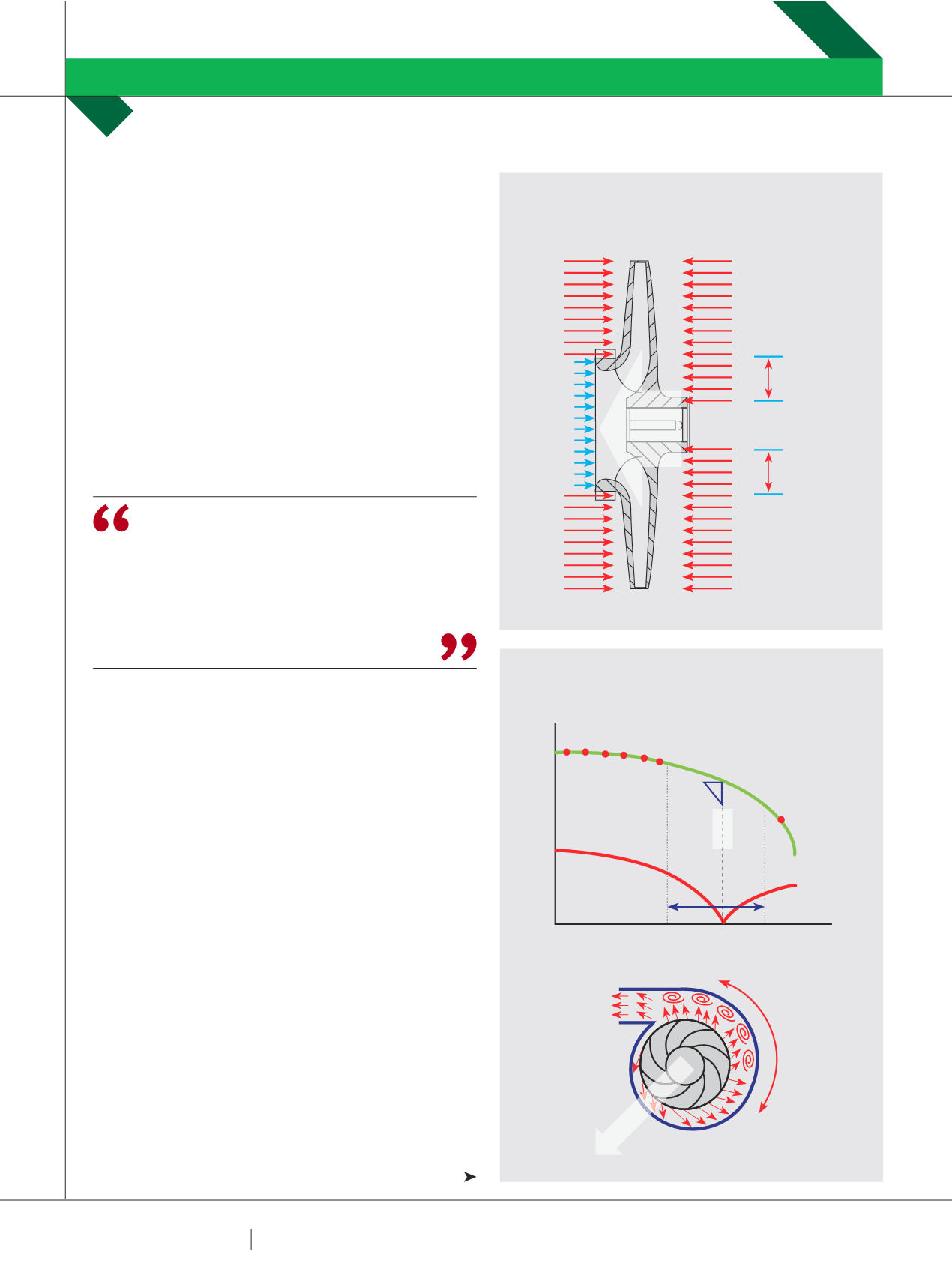

Fig 2 shows a simplified representation of smooth flow

at BEP versus the sort of flow disturbances that occur

at reduced flow. It does not take much to realise that the

distorted flow and turbulence will become worse the further

away you get from BEP.

The degree of turbulence and associated vibration and

buffeting depends on the hydraulic design and on the

energy levels in the pump. The effects are generally worse

for impellers with relatively large entry diameters. In larger,

higher energy pumps, vortexing (recirculation) can be so

severe that cavitation like effects ensue. It is possible to get

quite intellectual about this and we could discuss here such

aspects as the influence of Suction Specific Speed (Nss)

and the theoretical onset of recirculation. For the sake of

simplicity these details will be left for a later article.

AXIAL THRUST

Hydraulically unbalanced impellers generate an axial

thrust that is proportional to the differential head. Refer

to Fig 3 for a simplified representation of this effect. At

reduced flow, the differential head will be higher and the

generated axial thrust will increase. In multistage pumps

this thrust is generally handled by a balance device that will

automatically compensate, or by having impellers facing

opposite ends of the pump.

THE DEGREE OF TURBULENCE

AND ASSOCIATED VIBRATION AND

BUFFETING DEPENDS ON THE

HYDRAULIC DESIGN AND ON THE

ENERGY LEVELS IN THE PUMP.

PUMP SCHOOL

RON ASTALL

FIG 4: SINGLE VOLUTE RADIAL THRUST

FIG 3: HYDRAULICALLY UNBALANCED IMPELLER

FLOW

HEAD

HIGH TEMP RISE

LOW FLOW CAVITATION

REDUCED BEARING AND SEAL LIFE

REDUCED IMPELLER LIFE

SUCTION RECIRCULATION

DISCHARGE RECIRCULATION

RADIALTHRUST

CAVITATION DUE TO

LACK OF NPSHA

BEP

AT LOW FLOW

RADIAL THRUST

H

I

G

H

E

R

A

V

E

R

A

G

E

P

R

E

S

S

U

R

E

UNBALANCED AREA

OUTLET PRESSURE

OUTLET PRESSURE

INLET PRESSURE

OUTLET PRESSURE

OUTLET PRESSURE

UNBALANCED AREA

AXIAL

THRUST