5 2

PLUMBING CONNECTION

AUTUMN 2015

PRESS-FIT – PERFECTING YOUR PRESS (PROVIDED BY MM KEMBLA)

ACTION

WHY?

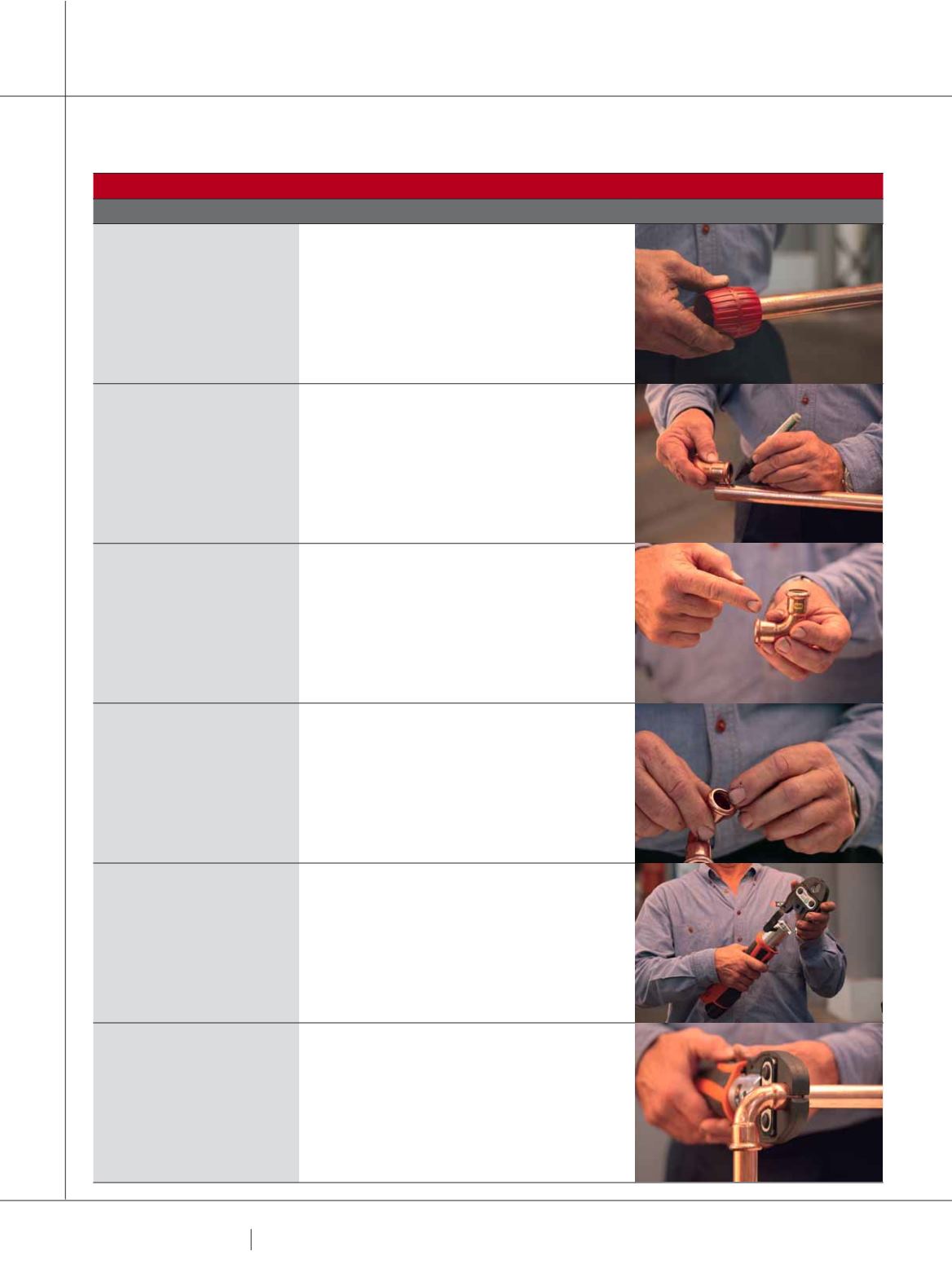

1.

Deburr the end of the

copper tube on both the

inside and outside

This is critical for press fitting connections, as

any burrs on the tube can damage the o-ring and

cause failure of your connection. It also minimises

turbulence and pressure loss.

2.

Mark the insertion depth on

your tube as per the product

installation instructions..

Correct insertion depths are fundamental to a

perfect press. Incorrectly inserted tube can lead

to failure of your connection. Marking the insertion

depth will ensure that any tube movement is

detected prior to pressing.

3.

Ensure you have the

correct fitting for the

application.

Press fittings are currently available for different

applications. Not all o-rings are suitable for all

applications, choosing the correct fitting is critical

to the integrity of your press connection. Refer

to product literature or contact your supplier for

application suitability.

4.

Check the sealing element

is correctly seated within the

fitting

Missing or damaged o-rings will lead to a failed

connection. The o-ring is integral to a complete

press connection.

5.

Ensure the jaw profile

is free of debris, grease or

damage. Jaws should be

cleaned after every use.

Any debris, grease or damage on a jaws inside

profile can lead to damage to the fitting upon

pressing.

6.

When closing the press jaw

onto the fitting, ensure the

jaw is placed square and at

right angles to the fitting.

A misalignment of the jaw and fitting can lead to

a failed press connection. Jaw and fitting should

always be aligned prior to activating the press.

JOINING COPPER