4 8

PLUMBING CONNECTION

AUTUMN 2015

It is important to consult with the manufacturer of the

fittings to determine which tools they warrant to be used

on their system. It is also important to note that the profile

of fittings is not the same across the board; for example, B

Press and Viega use a 3 point press, whereas the Kempress

fitting is a 2 point press.

For a step-by-step visual of the joining process, please

see page 52.

With so many benefits provided by copper press-fit

systems, let’s take a look at the four available in Australia.

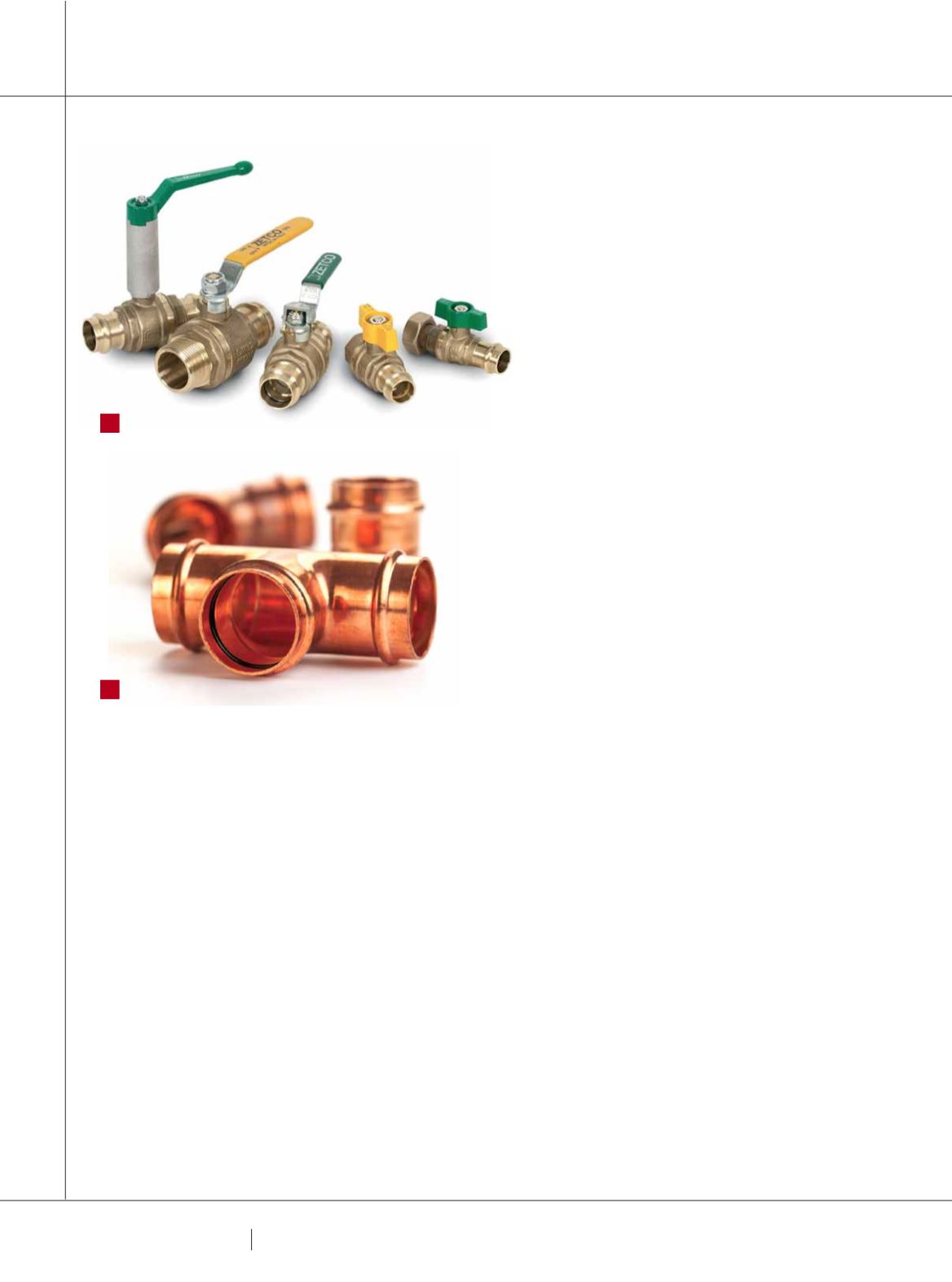

ZETCO

After two years in development, Zetco Valves recently

launched its new range of press-fit ball valves in sizes

15mm to 50mm, specifically designed for Australian copper

tube sizes.

Zetco Press-fit is a range of ball valves, designed and

manufactured with a built-in press connection. This

results in fewer joints, less mess and major savings

through reduced installation time. The integral connection

eliminates the use of additional fittings which means fewer

leak points for every valve. The range is manufactured under

Zetco’s high standards in Italy. Rigorous design and testing

has taken place to ensure that Zetco’s premium quality is

evident in this new range.

The gas ball valves are certified by the Australian Gas

Association (AGA) to AS 4617 and tested to DVGW VP614.

The water valves are WaterMarked by IAPMO R&T Oceana

to AS 5830.1. The press-fit ends have been tested to

AS3688 and the material composition complies with

AS2345.

With the press-fit connections built into the valve, the

new range can be used with existing V-profile tools from

Viega®, Rothenberger® and KemPress®, offering flexibility

while avoiding costly outlay on new tools.

Zetco Valves warrants that the joint pressed by a Viega®,

Rothenberger® or KemPress® V-Profile tool will not leak

for a minimum period of 25 years provided it is installed

according to the installation instructions provided with

every valve. Installation instructions can also be found on

the Zetco website.

CONEX >B<PRESS

Conex Bänninger was launched >B< Press in December

2011 to satisfy a growing demand for press-fit systems in

Australia.

Conex >B< Press is a versatile press-fitting system for

use with hard, half-hard and soft copper tube, providing

a secure, long-life, leak-proof joint. They are available in

Copper and Red Brass and are suitable for use with copper

tube to EN 1057.

>B< Press is installed with a mechanical press tool with

a compatible jaw to fit each size of fitting required. When

pressure is exerted through the press tool the joint is

permanently made and the fitting cannot be dismounted or

re-used. >B< profile has the advantage of a 3 Point Press,

which includes two mechanical presses either side of the

bead and one hydraulic press crimping the o-ring. They

claim this provides a more secure joint.

Conex has also developed a unique pressing indicator, a

specially designed EPDM o-ring. It has a reduced section

in two positions, causing leaks at low pressures when not

pressed (from 0.1 to 5.0 bar). When the fitting is pressed,

the o-ring material compresses, filling the gaps, securing a

leak-free path.

Therefore there is no need to go to full test pressure to

check that all fittings have been pressed. This >B< Press

feature is available in fittings sized 12-108mm and suitable

for hot and cold water applications.

Warranty is 25 year guarantee against faults caused

by defective manufacture of the fittings. It does not

cover faults arising from incorrect installation. The

warranty covers installation with type A and B copper tube

JOINING COPPER

IMAGE 1:

Zetco’s recently launched range of press-fit ball

valves.

IMAGE 2:

>B< Press is installed with a mechanical

press tool with a jaw to fit each size of fitting required.

1

2