4 6

PLUMBING CONNECTION

AUTUMN 2015

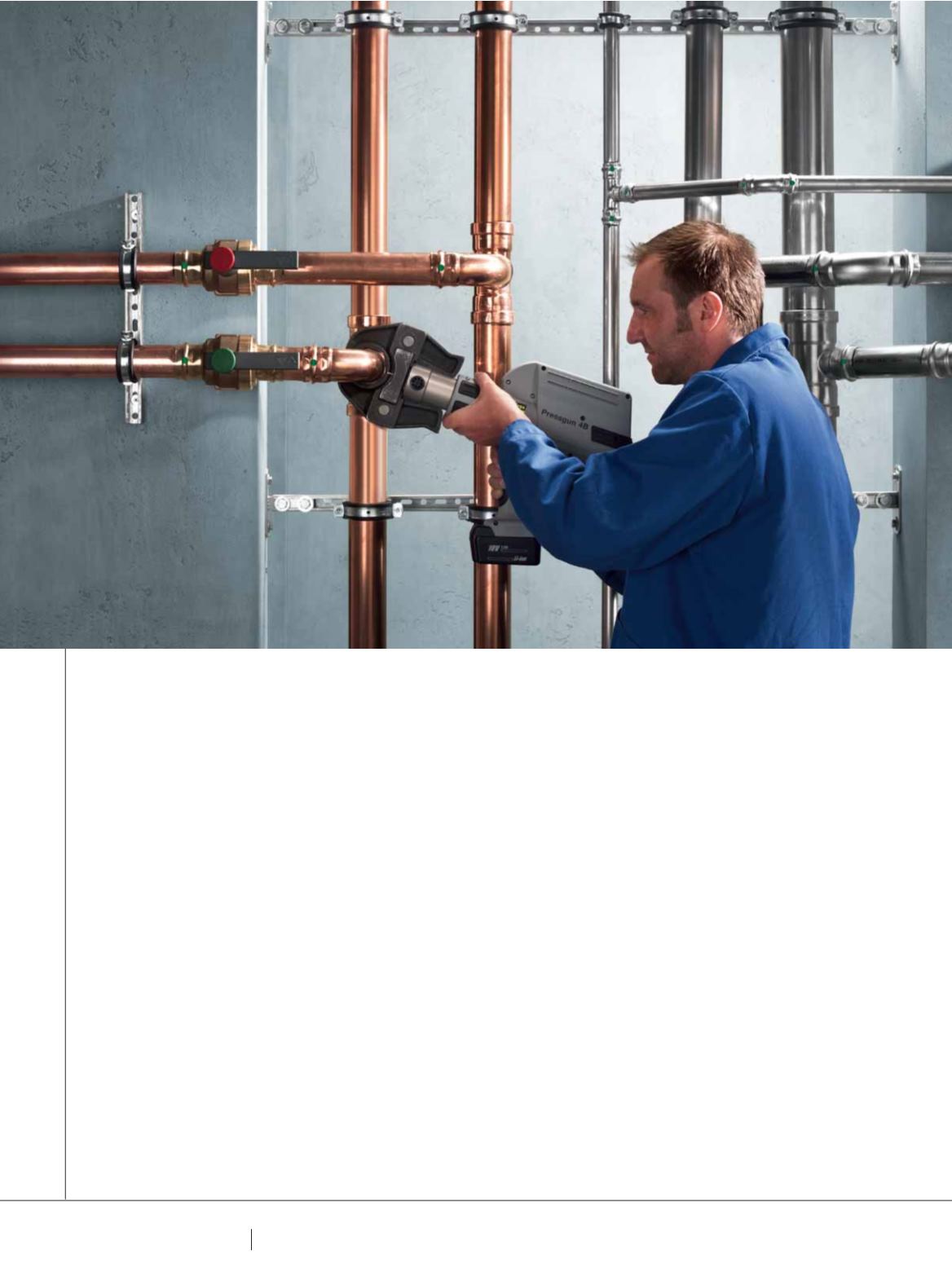

I

mproved on-site safety, enhanced joint performance

and finish as well as time-efficient installation are all

benefits that make it very clear as to why this joining

method is fast gaining ground on our shores.

Growing industry use of ‘press-fit’ technology has been a

major trend in Europe for over 25 years; however, Australia

has only been using press-fit since Viega introduced the

Propress system eight years ago.

Press-fit systems offer the advantage of flame free

installations, making soldering a thing of the past. Not

only does this make the job site safer by eradicating the

risk of fire, it also makes the job quicker, leading to greater

productivity and efficiency of labour.

Paul Mooney, Zetco Marketing & Business Development

Manager explains that, “The speed of installation is a

major benefit of press-fit. There are no hot work permits

required on major job sites meaning there is no need to carry

oxy and acetylene bottles and its performance is second

to none. There have been very few issues on job sites with

press-fit which gives the plumbers confidence that it is

a proven system. Another reason for the increased adoption

comes in the form of accessibility. Press-fit products

have grown dramatically with Reece, Plumbers Coop,

Samios and others all joining Tradelink with an offer in the

market place.”

The dramatic rise of press copper fittings has resulted in

them being the number one method for joining copper.

Adam Watson, Plumbing Business Development Manager

for Reece says, “We find that a lot of plumbers prefer to

use copper, however due to slower installation times they

have chosen alternatives. Now that there is a solution for

copper that is just as quick as the others it has been taken

to kindly.”

Systems are available for gas and water applications, both

of which are easily distinguishable via green (water) and

yellow (gas) indicators.

“The main difference between water and gas fittings is the

o-ring seal. The seal is the important part in this system. In

WITH SO MUCH ‘PLASTIC ADOPTION’ GOING ON IN THE INDUSTRY, IT MAY COME AS A SURPRISE TO HEAR THAT

COPPER PRESS-FIT SYSTEMS ARE GROWING IN POPULARITY WITH HYDRAULIC CONSULTANTS AND PLUMBERS

ALL OVER THE COUNTRY.

JUSTIN FELIX

REPORTS.

JOINING COPPER

THE PRESSING MATTER ON COPPER