2 0

PLUMBING CONNECTION Winter 2022

DIGITAL QA TICKS ALL THE BOXES

D

igital platforms using mobile

devices like smartphones

and iPads have affected all

industries, including commerce,

healthcare, education, retail, hospitality

– and now building and construction,

most notably in relation to the delivery

of evidence-based quality assurance

(QA).

QA in construction in recent decades

has sometimes been a ‘hit and miss’

affair, with many contractors and

subcontractors regarding their sign-off

obligations as ‘just another step’ in the

long bureaucratic journey towards job

completion and invoicing.

All that is changing. As happens so

often with major worksite innovations,

‘big construction’ (more than 25

personnel) is at the forefront of

cutting-edge reforms. This means

contractors and subcontractors wishing

to gain work with larger companies

need to be aware of these new digital

platforms – and willing and able to

use them. NB: digital QA platforms

are increasingly being adopted as

mandatory

procedures on worksites.

Furthermore, it seems inevitable that

digital QA practices will trickle down

from larger companies to small-to-

medium firms, as smaller outfits gain

familiarity with the technology and see

the many benefits of keeping ‘as you go’

digital records.

Why is digital QA so revolutionary?

Daniel O’Donoghue, co-

founder and Director of CONQA,

which creates and manages

customised digital QA

packages for the construction

industry in Australia and New

Zealand, says in-the-field

digital QA processes allow for

real-time data collection (including

imagery) that would be impossible using

traditional paper-based methods.

The primary motivation for using a

digital QA platform, Daniel explains, is

quite fundamental: a desire to create

better buildings. However, there are

plenty of additional advantages of

embracing digital QA.

“You remove as much of the

guesswork as possible from

the process,” Daniel says.

“Contractors and subcontractors

are professionals – they know

what they’re doing – so digital

QA is really just there to

make sure everyone

has completed

things right, that

everything is in

order, and they

can just move on with peace of mind

knowing they have checked everything.”

By creating a

meaningful

sign-off

process with real-time digital QA,

workers are motivated to deliver peak

productivity and performance in the

first instance. Signing off work ‘as you

go’ also removes the need for lengthy,

time-consuming, often imprecise,

retrospective reviews that can add

hours of desk work to a working week or

month.

“Digital QA, I should add, is also

massively used as a protection device,”

Daniel says. “We’ve got examples of

customers who have been able to

reduce their insurance premiums

because they can demonstrate that

they have done work correctly: for

example, the ability to prove that a fault

was attributable to a post-construction

Historically, worksite quality assurance has been a paper-based, retrospective chore rather than a

genuine record of procedural excellence. However, on-site digital QA platforms are changing the way

contractors and subcontractors sign off their work.

John Power

reports.

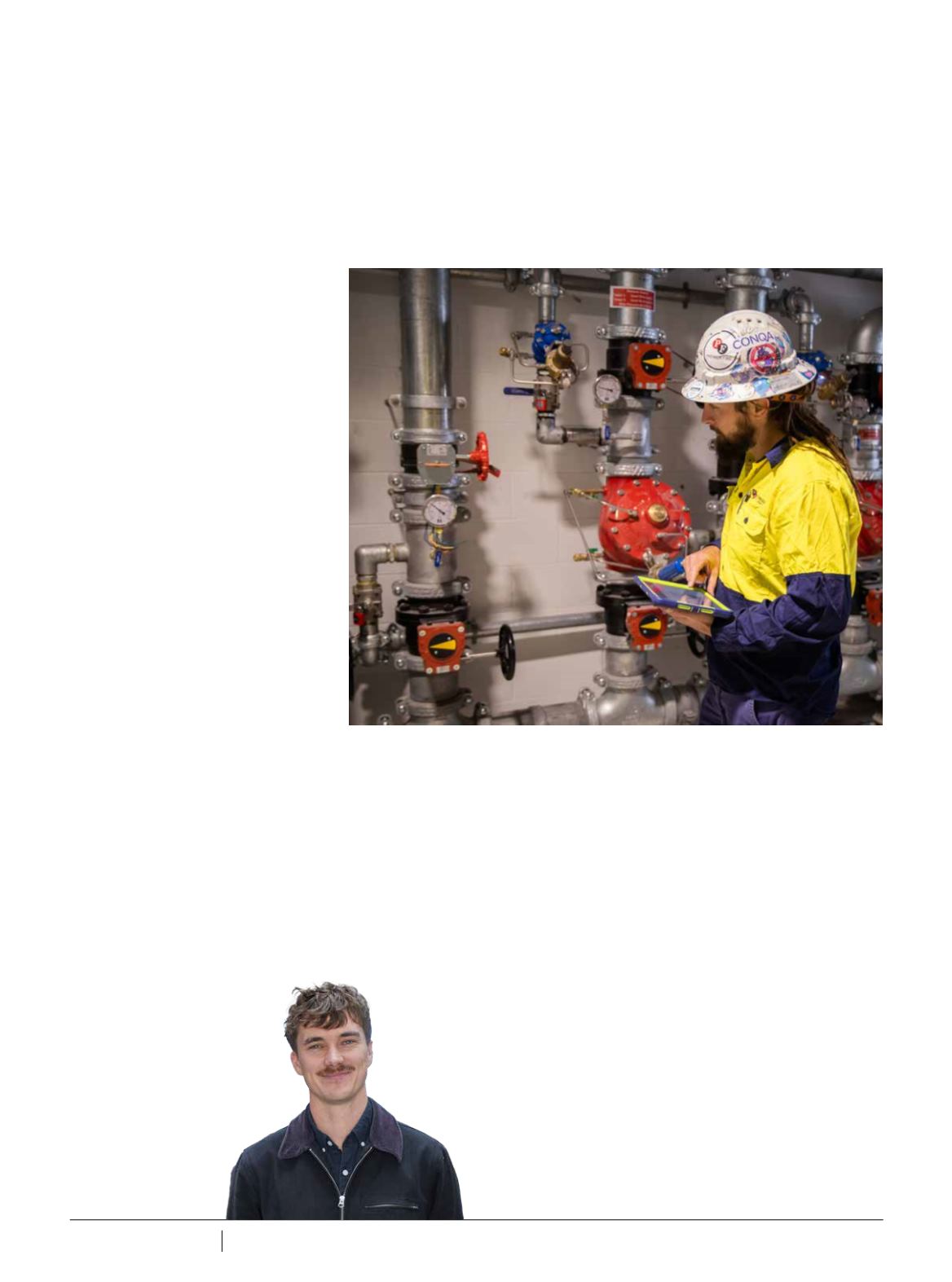

CONQA on site with Premier Services Group on Queen’s Wharf Brisbane being built

by Multiplex.

QUALITY ASSURANCE

Daniel O’Donoghue,

Co-Founder and

Director of CONQA.