5 6

PLUMBING CONNECTION

SUMMER 2016

events from around the world. The pumps are capable of

delivering 100 litres per second, which far exceeds the

maximum flow of 16 litres per second as set out in the

Australian Standard for box gutter design.

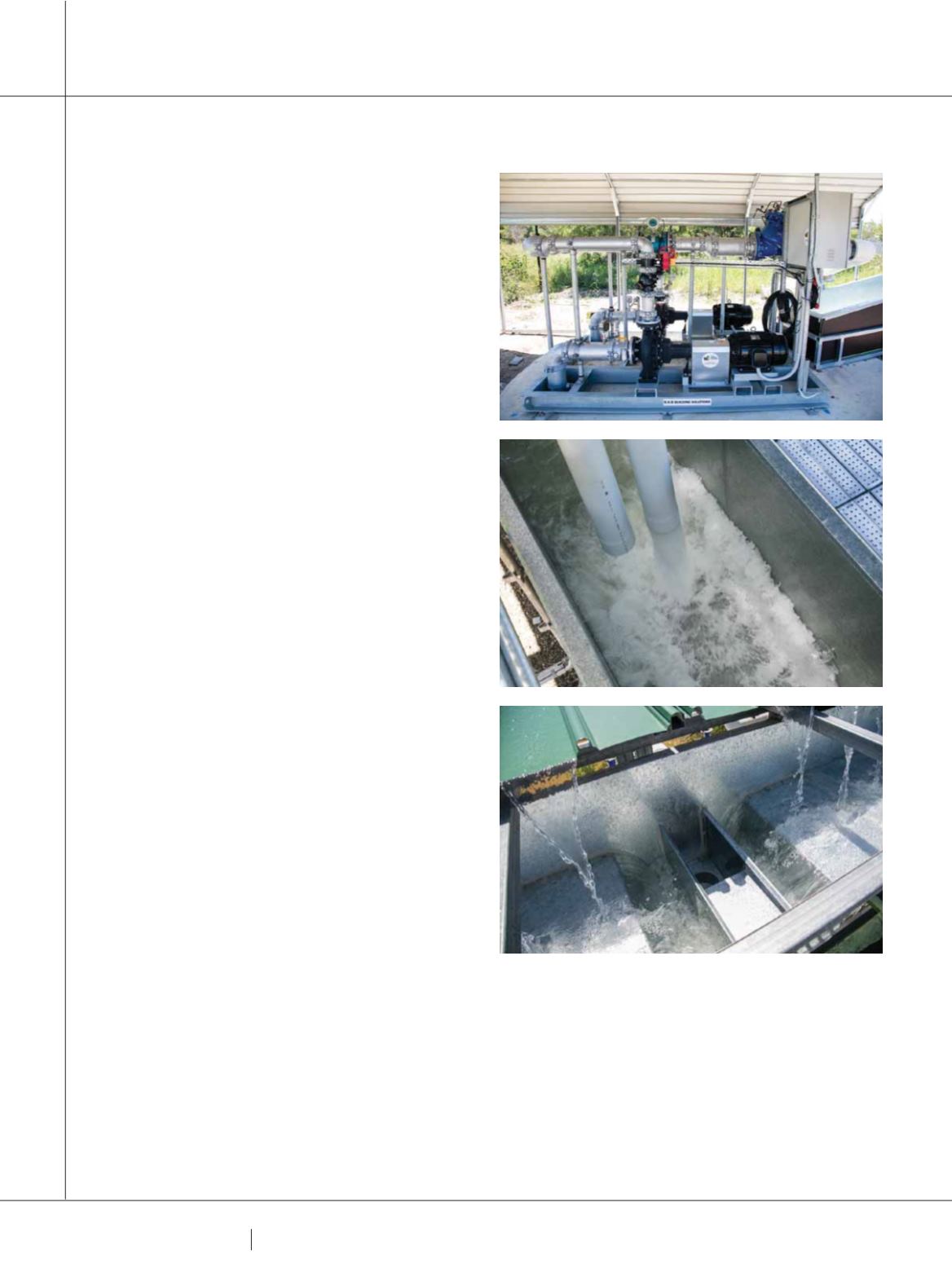

“When dealing with such high circulation flows (100 l/s)

uncontrolled wave generation within the tank can cause

cavitation and subsequent failure of the pumps,” Mark

explains.

“To counter this possibility, Terry and the team at

USC developed a simple but effective anti-wave baffle

constructed from a modified concrete stormwater pipe. This

is another demonstration of Dr Terry Lucke’s experience in

being able to implement a simple and reliable solution to a

complex problem. Terry’s ability in this regard has enabled

the overall costs of the Research Project to be much lower

than they would have been if we were working with a less

experienced team.”

The initial flow modelling results have already revealed

some remarkable results that will change the way the industry

think about roof drainage solutions. The development of

combination hybrid systems (gravity/syphonic) is one of the

advanced design solutions under review.

Having the ability to test and witness all the components

of the roof drainage system in concert (gutters, sumps,

overflow, outlets, downpipes) has provided the team with

a unique opportunity to observe and record the important

hydraulic relationship that one component of the system

has with another. This unique aspect of the AHSCA Research

Facility will assist in a better understanding of the hydraulic

characteristics that has not been possible in previous studies.

The Research Facility is also able to review and verify

currently available data that is included in various

references such as AS/NZS 3500.3. This provides the

opportunity for the research team to reverse engineer

current sizing guidelines to identify excessive safety

allowances (in addition to freeboard). Identification of

duplicated safety allowances will result in more realistic and

efficient outcomes for AHSCA members.

While the vast majority of the rig is completed and

commissioned, the research team is still developing one of

the extremely important and sensitive areas. A multitude

of measuring and recording devices has been trialled using

various technologies and the team is currently reviewing

the trial results of the various systems with the full

implementation and commissioning due in the upcoming

months.

Dr Terry Lucke also designed an oversized return flow

gutter at the base of the test rig that allows observations

of localised turbulent discharges from downpipes. This

type of configuration may be used where upper catchments

discharge to lower gutters. This addition to the rig allows

the opportunity for future research and the development of

further design solutions.

AHSCA UPDATE

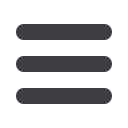

The test rig is impressive across the board and uses pumps

that are capable of delivering 100 litres per second.

“The return gutter also allows the observation of the

discharge flows from positive and negative pressure

environments at various flow rates. This will allow us to

development the most suitable connections of the roof

drainage systems to the in ground stormwater networks.

“The additional mid and lower working levels originally

incorporated into the design in the test rig by Dr Terry

Lucke has allowed additional research to be undertaken