TRADELINK – ON THE JOB

ADVERTORIAL

Cross-linking in PEX-B pipe takes

place after the pipe has been extruded

and coiled and is exposed to hot water

and steam. This results in cross-linking

that is less uniform than with PEX-A,

which is why PEX-B is stiffer and has a

distinctive coil memory.

A PEX SYSTEM YOU CAN TRUST

To ensure that PEX-A pipe meets

Australian manufacturing standards,

the TradePex factory follows strict

quality control and quality assurance

processes, overseen by Tradelink. This

requires product performance to be

reported at each step of production.

The product is tested continuously

from raw material through to extrusion

and coiling to ensure it meets

Australian Standards for tolerance,

cross-linking degree and pressure

testing, with a 100% success rate. The

facility also houses a state-of-the-art

testing laboratory that tests products

from other factories along with its own.

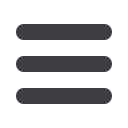

T

radePex delivers exactly what

plumbers need: a strong,

versatile and flexible PEX piping

system that will do the job for both

gas and water. Combining durability

with fit-out versatility, TradePex makes

your job easier without compromising

on quality. And, with the addition of a

new PEX-A water pipe, TradePex has

options – both crimp and sleeve – to

suit all plumbers.

FLEXIBILITY IS IN THE

MANUFACTURING

PEX-A is a cross-linked, polyethylene

(PE) pipe that is extremely durable,

even at short-term temperatures of

up to 95 degrees Celsius, and has a

high tolerance to wear and corrosion.

It’s the most flexible of all PEX tubing

types and has little to no coil memory,

which means that once straightened,

it won’t return to the original shape of

the coil.

PEX-A and PEX-B are both PE

pipe, but they are made through very

different manufacturing processes,

which give them distinct properties.

PEX-A is produced by adding

peroxide to the polyethylene during

the extrusion process, before the pipe

is coiled, creating cross-links in the

polyethylene through the combination

of pressure and temperature, and

transforming it into a cross-linked

polyethylene (PEX). The manufacturing

process for PEX-A creates more

uniform cross-linking, which is why

it’s softer and more flexible. The

more cross-linking, the more

flexible the pipe; TradePex

PEX-A pipe is cross-

linked to a minimum of

82%, giving you a pipe

that is flexible and easy

to work with.

tradepex.com.au1800 887 092

WITH THE ADDITION OF A NEW PEX-A WATER PIPE INTO THE MIX, TRADEPEX IS NOW THE MOST COMPLETE AND

ADVANCED PEX SYSTEM ON THE MARKET.

TRADEPEX, EVEN MORE FLEXIBLE

TRADEPEX PLUMBERS HAVE THE

BEST PEX

The TradePex system offers

premium temperature/pressure

ratings. All fittings are made from

high quality, dezincification resistant

brass (no plastic), and with just one

fitting for both gas and water, sleeve or

crimp, the TradePex system gives you

a key advantage over other systems on

the market.

Certified as compliant to relevant

Australian Standards by ApprovalMark

International and covered by a 25-year

insurance-backed, manufacturer’s

warranty, plumbers really do have

the best PEX when they choose

TradePex.

TradePex is available exclusively from

Tradelink.