5 0

PLUMBING CONNECTION

SPRING 2015

As you can see, it’s certainly not a straight forward project

and one best suited to someone with a technical trade

background or experience in the construction industry. For a

lot of students, it might prove a mountain too high to climb.

Thankfully a suitable candidate rose to the occasion. Luke

Verstraten decided to further his education at the University

of the Sunshine Coast after successfully running his own

irrigation and landscaping business for over 10 years.

“I graduated from my Bachelor in Environmental Science

Degree in 2011 and I received a university commendation

for my academic achievements. By the time I finished my

undergraduate degree I knew that I had developed a passion

for undertaking research projects that are practical and

relevant with benefits to industry and society,” Luke says.

Since graduating, Luke has worked on several national

and international collaborative research projects with the

Department of Agriculture, Forestry and Fisheries (Federal

and Qld), The Indian Ocean Commission, University of the

Sunshine Coast, Griffith University, La Trobe University and

the University of Queensland. While working on a national

research programme 3-year investigation into Soil Carbon

he was able to further his studies by completing his first

class Honours degree.

“I was particularly interested when I first heard about the

AHSCA project as I saw it as having the ability to expand

the current knowledge of roof drainage systems through

realistic physical testing on a scale that has not been

attempted before.

“I was therefore very keen on being involved with this

cutting-edge research project and I immediately applied

for the USC/AHSCA PhD scholarship. Fortunately I was

successful with my application and I am pleased to be

working with my PhD supervisors, Dr Terry Lucke and Dr

Helen Fairweather, who bring to the project a wealth of

experience and knowledge.

“Day-to-day activities will vary throughout the project.

Currently the construction and design of the testing rig

and reviewing of relevant literature are the predominant

activities. This is expected to be completed within the next

two months,” Luke says.

“Once the rig is constructed the experimental phase

will begin and we will start by testing a number of gutter,

sumps, overflow and down pipe configurations at flow rates

of up to 100L/s. To my knowledge this is the first project

globally to investigate conventional gutter systems on this

scale at these flow rates and much of this capacity is owed

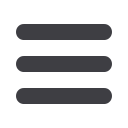

to the one off pump designed and built for the project by

Grundfos.

“As data is collected we can begin to analyse the

performance boundaries of roof drainage and develop

models to aid the hydraulic industry in making accurate and

informed performance based design choices.”

The dual pump system, developed by BKB Grundfos sees both pumps able to simulate up to 50L/s.

INDUSTRY RESEARCH