2 8

PLUMBING CONNECTION

SPRING 2015

COLOUR BLINDED

A

standardisation of pipe marking helps prevent

possible confusion, injury, and other hazards. This is

where the Australian Standard

AS1345 Identification

of the contents of pipes, conduits and ducts

comes into

play. It pays not to make assumptions when it comes to pipe

colours though; especially where gas is involved.

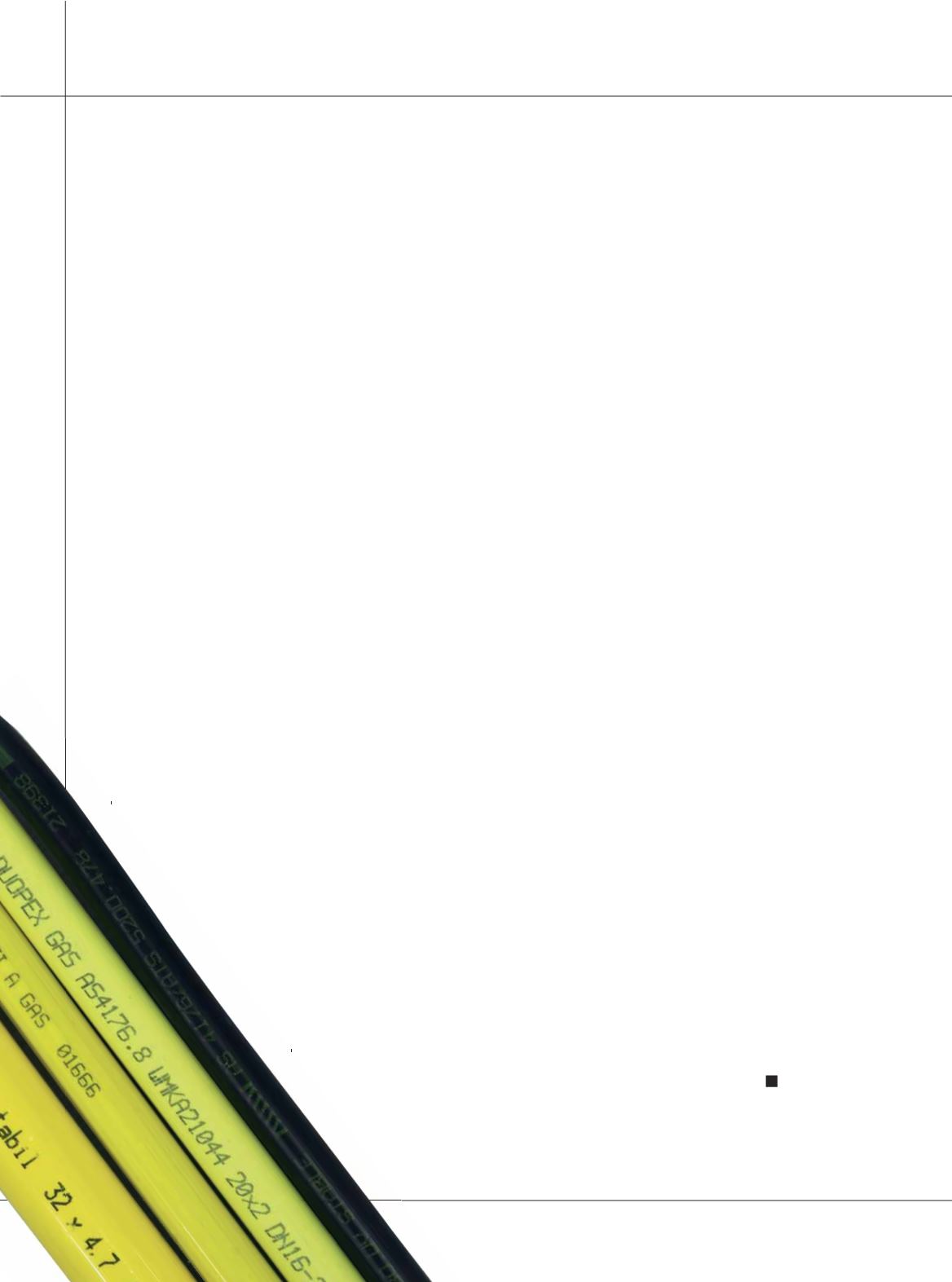

Most gas pipe manufacturers make their composite pipe

all yellow so it’s easily distinguishable. Using the term ‘most’

is a scary thought in itself because it means that at least

one pipe manufacturer has chosen to do things differently.

Not only does this mean that plumbers can be misled, it also

makes for a dangerous proposition.

Regulations state that composite gas pipe is generally

yellow with black lettering; black pipe with yellow lettering is

also acceptable. The pipe markings must include: AS4176,

maker’s name, gas/pipe size, materials used, date of

manufacture and licence number.

The pipe in focus is actually black with yellow print. This,

according to the Standard is enough to distinguish the pipe

as suitable for gas. The problem with that is the fact that

writing on pipes rubs off quite easily. The other problem

stems from a lack of product awareness or knowledge

that the Standard specifies that yellow writing is all that

is needed to identify the product as a gas pipe. When a

plumber has only ever known gas pipes to be yellow, it

would be fairly easy for them to mistake this product

as one.

You can no doubt picture the following scenario:

a plumber installing an air conditioner enters

a premise and turns the water off at the

mains. He drains the taps and climbs into

the roof to work on the air con. He cuts

the black pipe under the assumption

it’s for water and then lights a quick

cigarette. While some would argue

he shouldn’t be smoking up there

or on the job, it’s a very real

prospect.

It’s a scary thought,

isn’t it?

This isn’t

bureaucracy gone

mad; it actually

hasn’t gone

mad enough.

Cross connection is always a danger and it does happen

more often than installers are prepared to admit! Apart

from the ignition danger, water in gas lines or vice versa is a

very dangerous and expensive outcome.

“The identification of pipework in general, is an interesting

one,” Manager, Type A Gas Appliance Safety Energy Safe

Victoria Enzo Alfonsetti says.

“When you look at the relevant product standard

for composite pipe, it doesn’t really specify a colour

requirement so composite pipe manufacturers can virtually

design their product to whatever colour they want.”

The thing is, there is a requirement in the Gas Installation

Standard (clause 5.1.12 identification of pipework) that

makes things interesting. It states:

except in single

occupancy residential premises (domestic dwellings) above

ground consumer piping shall be identified when one of the

following applies:

∫ The operating pressure of the consumer piping exceeds

7kPa

∫ Where the location of the pipe is such that it is not readily

identifiable as consumer piping

This puts the onus back on the installer to decide whether

or not the pipe is really identifiable as consumer piping or

not.

There are requirements in situations other than

single residential where the pressure is over 7kPa. Most

households won’t have to meet those requirements. It is only

an issue in commercial buildings and the like. If you were

using the black pipe in a commercial environment where the

pressure was greater than 7kPa, it would be an issue.

When it comes to the Product Standard for composite

pipe, there is no specific requirement for colour.

“If you are using black composite pipe, be wary that if you

are using it in a commercial or any installation other than

a single occupancy residential premises, that there are

specific marking requirements where either the pressure

exceeds 7kPa or it’s not readily identifiable,” Enzo says.

When working with pipes, be sure to check and double

check that what you are working with is in fact a gas or

water pipe. They’re not all yellow after all.

IT IS COMMONLY ACCEPTED AMONG PLUMBERS THAT COLOURS MAKE IT EASY TO IDENTIFY VARIOUS PIPES AND

THE MATERIALS THEY ARE SUITABLE TO TRANSFER. IT IS ALSO COMMON FOR PLUMBERS TO ASSUME THAT ALL

GAS PIPES ARE YELLOW... BUT THEY’RE NOT.

PLUMBING CONNECTION

REPORTS.

LEFT:

It’s easy to assume that all gas pipes are yellow;

however, as shown here, black gas pipes exist too.

GAS PIPE IDENTIFICATION