3 8

PLUMBING CONNECTION

WINTER 2016

FORM LOSSES

The other type of pressure losses in pipe systems are

Form Losses. These are often referred to as Minor Losses

because in a typical system, these losses are usually much

less than friction (Major) losses. Form Losses are caused

by the excessive turbulence generated in the fluid when it

has to travel through pipe fittings and other components.

For example, when a fluid has to travel through a valve, or

around a bend, this causes significant turbulence which

makes it more difficult for the fluid to flow. This results in the

fluid losing pressure (energy).

Fittings and components that cause pressure losses in

pipework are generally allocated a form loss coefficient

designated as a K factor (Table 1). To estimate the pressure

loss (H

L

) due to a component or fitting, the K factor is also

simply applied to the velocity head as shown in Equation 2.

EQUATION 2

where:

H

L

= Minor (form) loss (m)

K = Form loss factor (dimensionless)

V = average pipe flow velocity (m/s)

g = gravitational force on earth (9.81m/s2)

Example 2

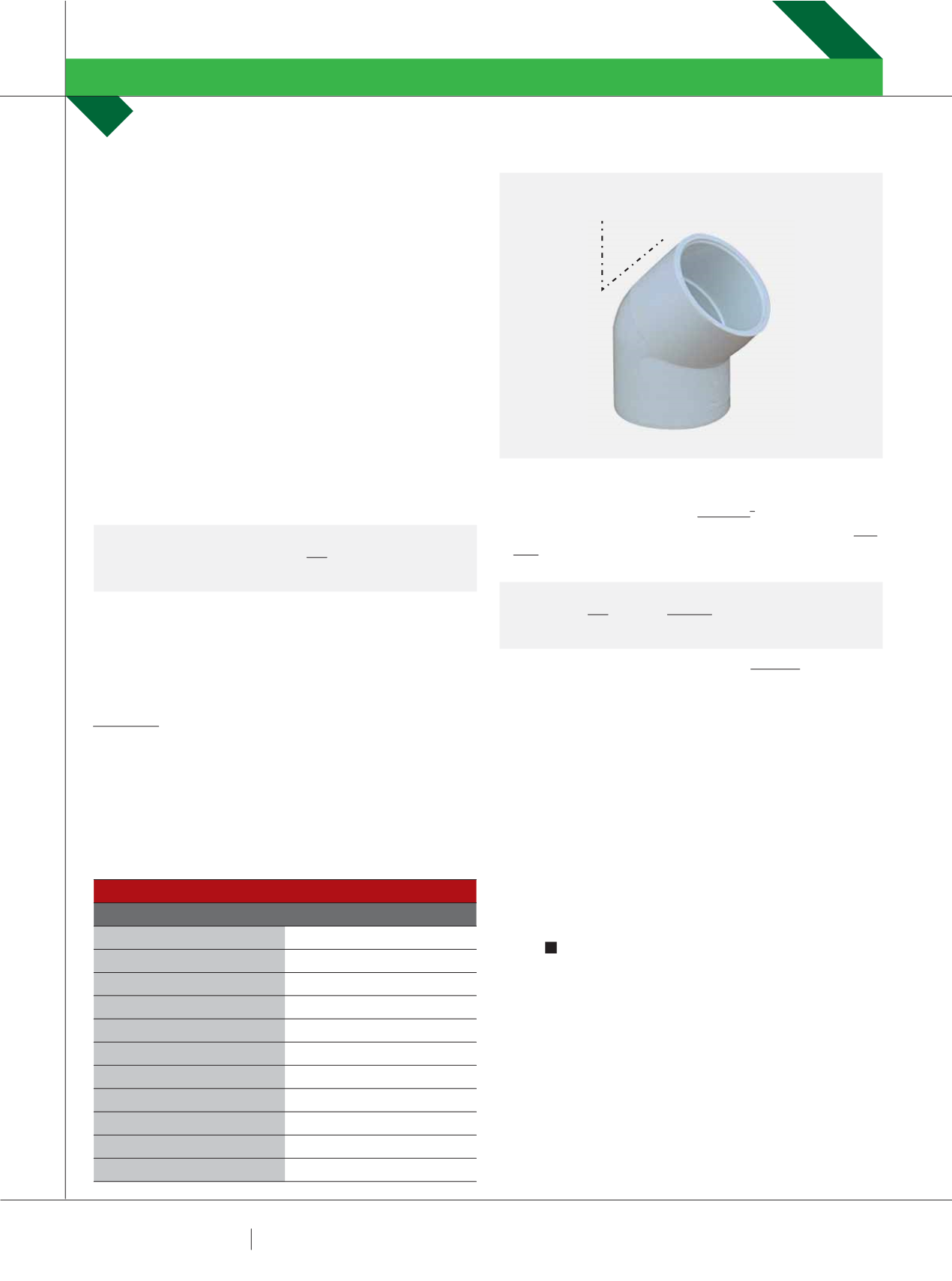

Calculate the headloss (m) through the Ø80mm, 45° PVC

bend shown in Figure 4 when the flowrate (Q) is 15 L/s. The K

factor for the bend is 0.3.

Solution:

∫ First we need to calculate the velocity in the pipe (V =

Q/A).

TABLE 1 – TYPICAL K FACTORS OF COMMON VALVE AND FITTINGS

Valve or Fitting

K factor

Globe Valve – Wide open

10

Globe Valve – ½ open

12.5

Gate Valve – Wide Open

0.2

Gate Valve – ¾ Open

0.9

Gate Valve – ½ Open

4.5

Gate Valve – ¼ Open

24

Return bend

2.2

Standard Tee

1.8

45° elbow

0.3

90° elbow

0.9

Ball check valve

4.0

∫ Area =

ʌ

D

2

/4 =

ʌ

x 0.08

2

/ 4 = 0.005 m

2

∫ V = Q/A: Velocity = Q (0.015 m

3

/s) / Area (0.005 m

2

) = 3.0

m/s

∫ Now insert values into Eq. 2:

So the minor head loss in the elbow = 0.138m (ans).

To calculate the total pressure losses in a pipe system, we

simply go through and sum the individual Major and Minor

losses in each section. As long as the total pressure driving

the system is greater than the total losses, we have flow.

If not, we need to either increase system pressure (bigger

pump or potential head), reduce Major and Minor losses

(better design or larger pipes), or a combination of both.

I hope this article has helped to improve your

understanding of pressure losses in pipe systems due to

friction and form losses. I have purposely tried to simplify

the article as much as possible to make it easier to

understand. The underlying fluid mechanics principles are

obviously a bit more complicated than this, but not that

much.

Please feel free to email me any comments, questions or

suggestions at

tlucke@usc.edu.au.

Contact:

Dr Terry Lucke

Associate Professor in Hydraulic and Civil Engineering

School of Science and Engineering

University of the Sunshine Coast

Building H1.Room 2.48

QLD 4558 Australia

Email:

tlucke@usc.edu.auHYDRAULIC CLASSROOM

DR TERRY LUCKE

H

L

K

=

V

2

2g

H

L

K

=

V

2

2g

0.3

0.138 m (138mm)

=

=

3.0

2

2*9.81

FIGURE 4 – Ø80MM, 45° PVC BEND

Ø80mm

45º