5 8

PLUMBING CONNECTION

WINTER 2015

This recirculation can produce high vibration levels,

surging, axial shuttling of the shaft and mechanical damage

to the impeller and casing. When severe at low flows,

recirculation cavitation like damage will be evident on the

pressure (non visible) side of the impeller eye vanes.

This should not be confused with classic cavitation

damage due to inadequate NPSHA which will appear on the

visible low pressure side of the impeller vanes. The noise

from recirculation will be similar to cavitation noise but is

more random in character. Typically, recirculation noise will

reduce as the flow is increased, whilst classic cavitation

noise will normally increase with higher flows. These

problems will impact on other areas of the pump affecting

the reliability of seals and bearings in particular.

Research by J. L. Hallam, studying 480 pumps and 1881

failures over a five year period in the refining industry

concluded that pumps with high values of NSS (above

12,800 in metric units or 11,000 in US units) had a failure

rate approximately double that of lower NSS pumps.

This has resulted in many Oil Industry specifications

applying arbitrary limits on NSS.

Overall, this is not a bad thing, but it is important to

remember that it was a statistical survey and such an

arbitrary approach may reject a few perfectly good pumps

that have tested out as smooth units despite having a

high NSS. It is also important to remember that a well

selected pump with a higher value of NSS will still be a

better proposition than a pump with low NSS selected near

minimum flow.

The benefit of this knowledge is as a tool to predict the

likely NSS requirement for the pumps at the system design

stage. This gives the designer the option to raise vessels

etc. if it looks like the original system NPSHA will result in

the need for pumps with a narrow hydraulic stability range.

IMPACT ON MINIMUM FLOW

Most commercially available pumps now comply with

the upper limit of NSS as a matter of routine, but there

may be some pumps in the field with high numbers for this

parameter due to suction constraints. Pumps with a High

PUMP SCHOOL

RON ASTALL

vale of NSS will probably be much more sensitive to low

flow operation and additional care will be required, such as

setting higher minimum flow values for these units.

*This article originally appeared in Pump Industry

magazine. For a limited time, readers of Plumbing

Connection can subscribe for free to Pump Industry

magazine. Go to

www.pumpindustry.com.au/pc/now to take

up this offer and get more information on pumps.

IT IS ALSO IMPORTANT TO

REMEMBER THAT A WELL SELECTED

PUMP WITH A HIGHER VALUE OF NSS

WILL STILL BE A BETTER PROPOSITION

THAN A PUMP WITH LOW NSS

SELECTED NEAR MINIMUM FLOW.

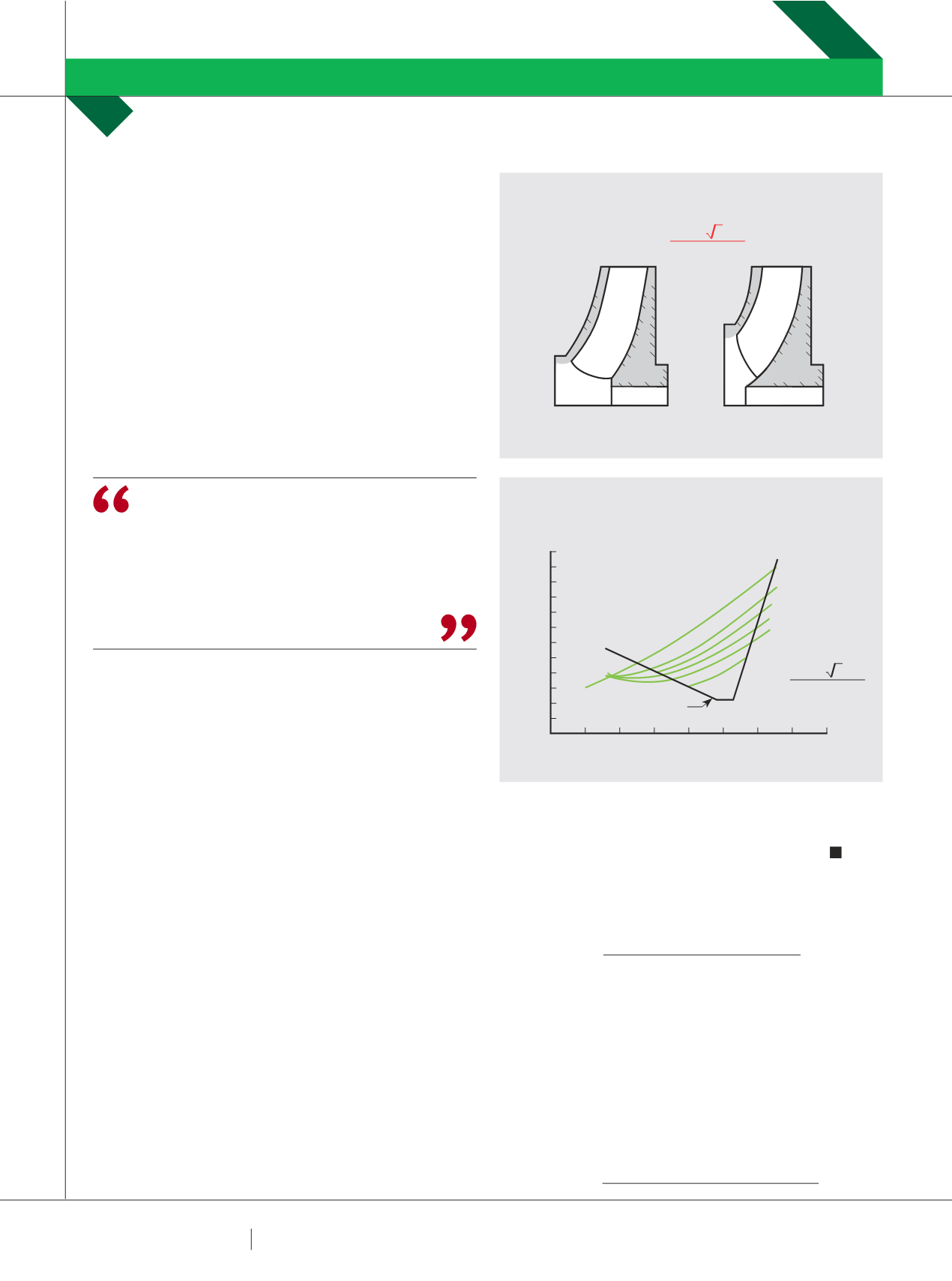

FIG 4: STABLE OPERATING

WINDOW VS SUCTION SPECIFIC SPEED

CAPACITY % OF BEST EFFICIENCY

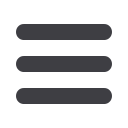

FIG 3: SUCTION SPECIFIC SPEED

LOW Nss

(HIGH NPSH)

HIGH Nss

(LOW NPSH)

N

SS

=

NPSHR

3/4

Q

N.

NPSH - ft

60

50

40

30

20

10

0

0

20

40

60

80 100 120 140

N

SS

=

NPSHR

3/4

Q

N.

ROSS/LOBANOFF CURVES

(USGPM. FT. RPM)

STABLE WINDOW

7000

8000

9000

10000

11000

12000

20000

Ron Astall is a Mechanical Engineer with extensive

pump industry experience including Engineering, Contract

Management, Applications, Sales, Marketing and Quality

Assurance; particularly in the Process and Petrochemical

Industries in his role at United Pumps Australia.

With his consultancy, Astech Pumping Services and through

Strategic Achievement, he has also been an active provider of

pump industry training. Ron is the current President of Pump

Industry Australia (PIA) and Contracts Manager at United

Pumps Australia.

www.strategicachievement.com.au