5 6

PLUMBING CONNECTION

WINTER 2015

T

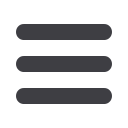

o recap, Fig 1 is generalised but provides a convenient

overview of the symptoms associated with low flow

operation issues such as:

∫ Increased internal turbulence

∫ Recirculation

∫ Increased pressure fluctuations

∫ Increased vibration due to the above

∫ Increased axial thrust – depending on pump hydraulic

balance method

∫ Increased radial thrust; particularly with single volute

casings

∫ Temperature rise due to high internal energy loss

In this article we will look at the parameter “Suction

Specific Speed” (NSS) and how it influences low flow

stability in a centrifugal pump.

FLOWREVERSAL AND VORTEXING AT LOW FLOW

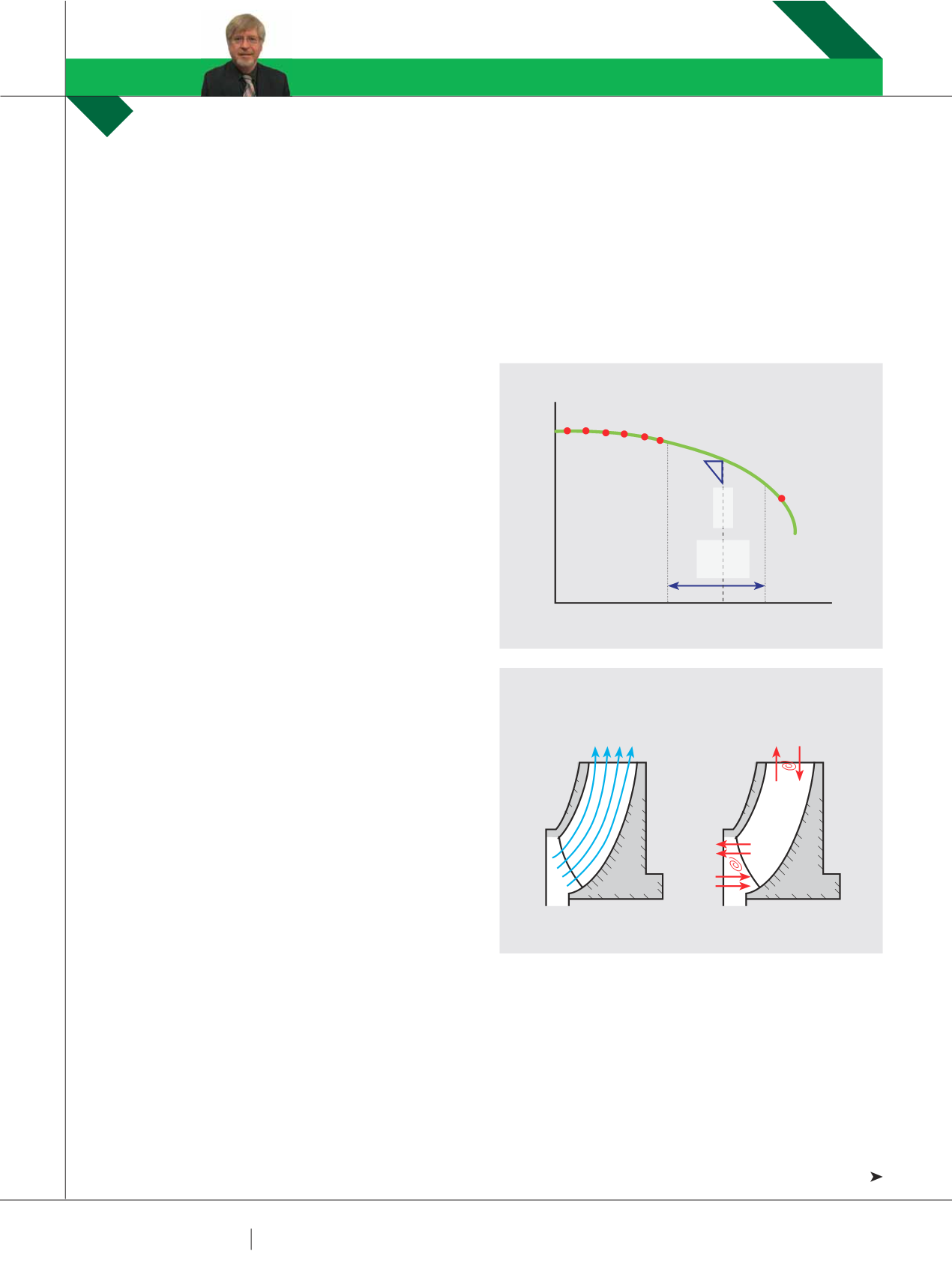

Again, from our last discussion, Fig 2 shows a simplified

representation of smooth flow at BEP versus the sort of flow

disturbances that occur at reduced flow.

The degree of turbulence and associated vibration and

buffeting depends on the hydraulic design and on the energy

levels in the pump. The effects are generally worse for

impellers with relatively large entry diameters. In larger

higher energy pumps, vortexing (recirculation) can be so

severe that cavitation like effects ensue.

“Suction Specific Speed” (NSS) is a design parameter

that can be used to predict how susceptible a pump may be

to recirculation and instability at low flows and also at high

flows.

NSS gives an indication of the priority given to suction

performance for a given impeller.

It is calculated as follows :

∫ Where N is the running speed in rpm, Q is the flow per

impeller eye at best efficiency and using the NPSHR at

best efficiency flow.

PUMPS DESIGNED FOR VERY LOWNPSH

For a given flow, a higher value of NSS denotes improved

suction performance (low NPSHR). Fig 3 shows the typical

variation between a low NSS impeller and a high NSS impeller.

The high NSS impeller has a much larger eye diameter, which

reduces velocities and thus entry losses for improved NPSHR.

TRADE OFFS

Unfortunately, by virtue of this larger eye diameter, this

type of impeller is much more prone to flow instability

and recirculation when operating at flows away from best

efficiency. Considerable research has shown that the range

of stable operation is dramatically reduced at higher values

of NSS. This is shown graphically in the hydraulic stability

guidelines in Fig. 4 (US units).

The primary problem created is recirculation which can

occur at the pump inlet and at the outlet of the impeller at

partial flows and, less frequently, at high flows.

UNDERSTANDING PUMP CURVES

#6: MINIMUM FLOW –

PART TWO

IN HIS LAST DISCUSSION,

RON ASTALL

LOOKED AT WHAT HAPPENS WHEN A PUMP IS OPERATED IN AN OFF DESIGN

CONDITION, IN PARTICULAR, LOW FLOWS. HERE HE ELABORATES ON THE SUBJECT.

PUMP SCHOOL

RON ASTALL

FIG 1: HEAD VS. FLOW

FIG 2: FLOWDISTRIBUTION

IDEAL FLOW

DISTRIBUTION

DISTORTED FLOW

REVERSAL VORTEXING

FLOW

HEAD

HIGH TEMP RISE

LOW FLOW CAVITATION

REDUCED BEARING AND SEAL LIFE

REDUCED IMPELLER LIFE

SUCTION RECIRCULATION

DISCHARGE RECIRCULATION

CAVITATION DUE TO

LACK OF NPSHa

BEP

PREFERRED

SELECTION

ZONE

BEP

LOWFLOW

COURTESY PIA AUSTRALIAN PUMP TECHNICAL HANDBOOK