2 0

PLUMBING CONNECTION

WINTER 2015

with a device to calculate the sound coming through on the

other side. We can’t put a speaker in a pipe though.”

Acoustic lagging comprises a noise barrier to contain

pipe-wall vibrating noise. There are several types of

materials used for this purpose, including loaded vinyl and

convoluted foam. Each material will have a U-Factor, which

is a performance rating that measures how well a given

material prevents heat from escaping.

Let’s look at available products from three reputable

Australian suppliers.

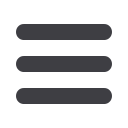

ACOUSTICA GREENLAG

GreenLAG® pipe lagging was developed to contain

the intrusive noise generated by the turbulent flow of

wastewater through pipes, fittings and general noise break-

out from ductwork, fan housings and the like in residential,

commercial and industrial buildings.

Philippe Doneux, Engineer at Acoustica describes some of

the benefits of its product.

“GreenLAG uses a soft and cellular structure which

increases vibration dampening. This allows for us to use

15mm foam as opposed to 25mm which most others use. It

also means that for a given weight and thickness, GreenLAG

will achieve a better STL (Sound Transmission Loss) than

other products in the market.”

Acoustica also claim that another direct consequence

of reducing material thickness is the reduction of the

vibrations radiating surface, when lagged over pipe.

Pipe lagging has traditionally known to be laborious and

time consuming; however Philippe believes this is changing

thanks to experience and advanced skill sets.

“The professionals lag quite quickly now and teams of

people exist who specialise in the field. These guys don’t

need to take patterns to cut for different junctions and the

like – they can do it all by eye now. It’s a bit like the old metal

workers who could cut metal the right way.”

Keeping the installers happy by working into their regimes

makes it all the more straight forward too.

“Depending on how the laggers like to have the material,

we supply it in different lengths. There is a company in SA

that uses women to do the lagging so they ask that the rolls

of lagging are not overly heavy. We provide them with 3m

lengths by 1.3m wide. We can supply in longer rolls up to

5m by 1.3m wide as well. We’ve definitely noticed a shift to

shorter rolls though. It makes for easier navigation through

stairwells and other tight spaces.”

When it comes to installation, Philippe assures that

working with GreenLAG is simple and straightforward.

“It’s very easy to cut with a knife or scissors, particularly

with the thinner material being employed. We suggest to

installers that they always overlap by about 50mm rather

than butt joining the material. We also suggest they use a

longitudinal reinforced aluminium tape that goes over the

ACOUSTIC PLUMBING

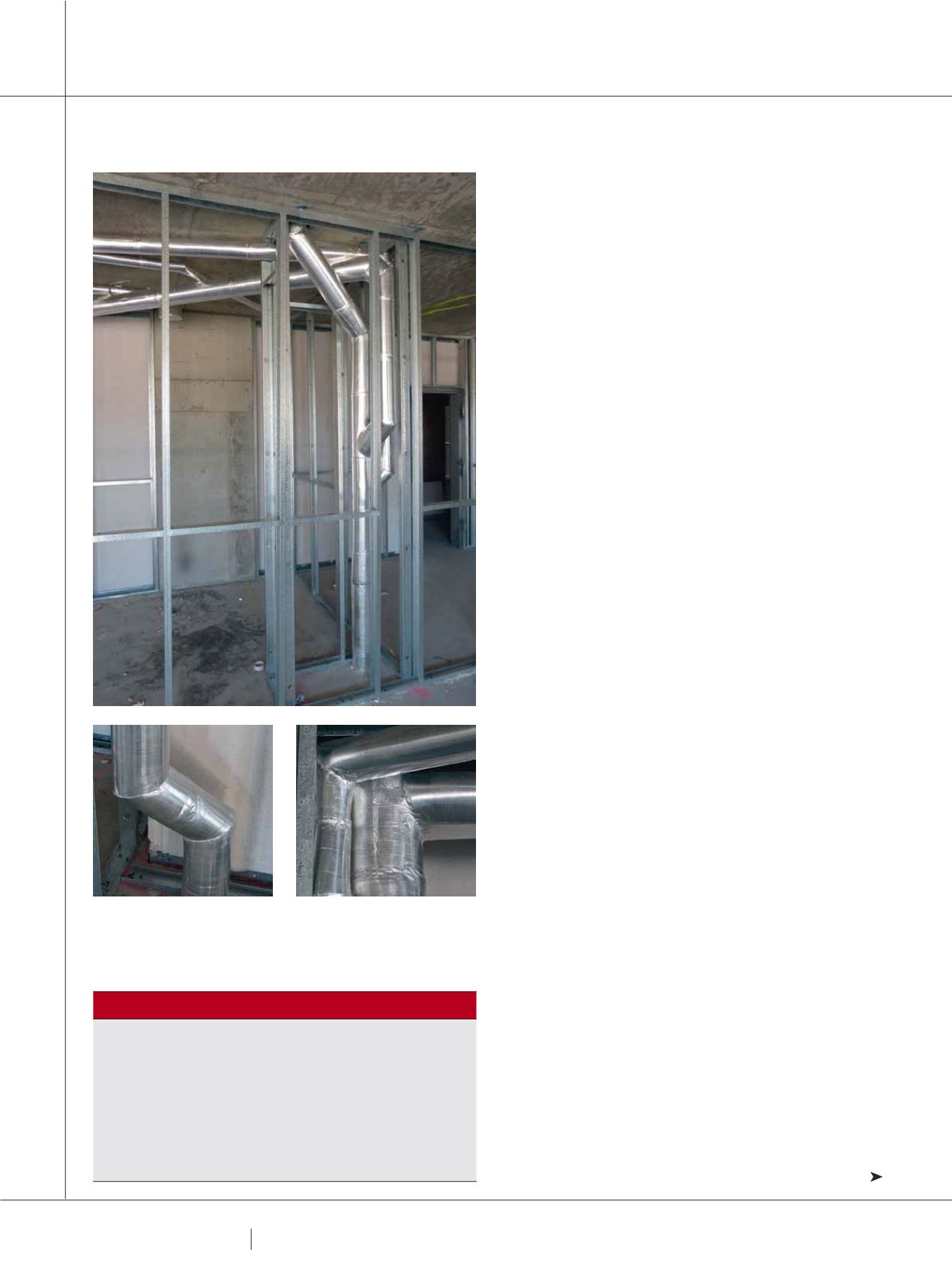

Acoustica GreenLAG uses 15mm foam rather than 25mm.

They claim that the soft cellular structure helps to achieve a

greater Sound Transmission Loss than other poducts.

NCC 2011 REQUIREMENTS: F5.6

Sound Insulation rating of services a) If a duct, soil, waste or water

supply pipe, including a duct or pipe that is located in a wall or floor

cavity, serves or passes through more than one sole-occupancy

unit, the duct or pipe must be separated from the rooms of any

sole-occupancy unit by construction with an Rw + Ctr (airborne) not

less than - i) 40 if the adjacent room is a habitable room (other than

a kitchen); or ii) 25 if the adjacent room is a kitchen or non-habitable

room.

b) If a storm water pipe passes through a sole-occupancy unit it

must be separated in accordance with a) i) and ii).