4 0

PLUMBING CONNECTION

AUTUMN 2015

flow factory. Needless to say, he was thoroughly impressed

with their extensive facilities and approach to their daily

work activities.

“We were given an unbelievable reception by the Noritz

team. We met with the 88 year old founder of the business

and got to meet the Noritz Board. While it is publicly listed,

the founder is still a significant shareholder and active in the

business. We had a great chat with him.

“The scale of the factory is something I’ve never

seen before. To say it is massive would be an incredible

understatement. You can’t see it all in a day and this is just

the main factory. It has a series of multi-storey buildings

spread across 30 acres. There were 17 production lines in

the main factory alone and you think to yourself that Noritz

has got another 14 factories around the world.

“We were so impressed with their manufacturing

capability and their undeniable commitment to quality.

Customers in Japan told us that it regarded as the premium

brand over there. Justifiably, Noritz has got an incredible

amount of pride in both their product and their operations.

They’re simply world class,” Simon exclaims.

With that in mind, it’s obvious that Dux will leverage from

their sheer scale. They will also begin to supply continuous

flow and a range of commercial hot water products that they

have previously lacked. It’s a win-win situation at the end of

the day.

“They have over 500 R&D engineers and a five storey R&D

centre at the Akashi site. We walked through it with our jaws

on the floor. It was like the Disneyland of hot water. Nothing

was off limits to us and let me tell you that they have some

amazing products in development.

“We also spent a lot time with the factory teams. It

seemed like every corner we turned around exposed us to

another piece of machinery worth millions, which we had

always wanted, but couldn’t afford because of our smaller

size. Now we can leverage that scale to support better built

products.

They don’t just bring size and technology to the party

either as their work ethic and communication approach is

second to none too. And it is in the areas of communication

and employee engagement whereby Simon believes Dux

management can learn and adopt new practices.

“On their first trip, the senior management addressed the

whole Dux factory. They stood at the door and introduced

themselves to every worker on the shop floor as they

entered and then gave a short presentation on their plans.

The factory stood up and cheered at the end. Dux is a pretty

big employer in regional NSW and our workers have a lot

invested in our business. Like me, they think that Noritz is

the best possible partner for Dux in Australia.”

So what can we expect from the company in the coming

future?

“It’s very much business as usual,” Simon explains.

Dux

www.dux.com.auNoritz

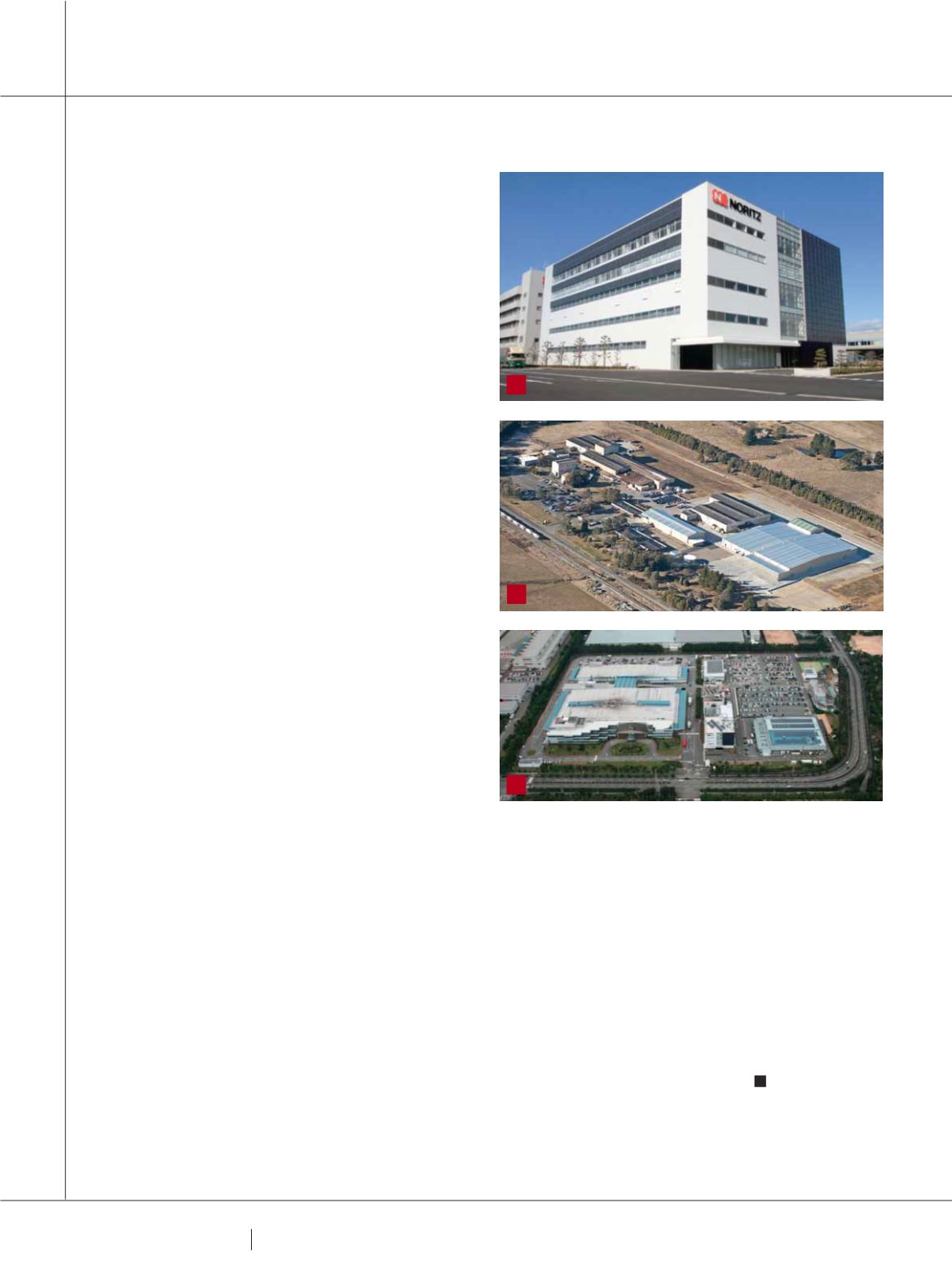

www.noritz.comIMAGE 1:

Noritz Japan’s R&D centre at the Akashi site.

IMAGE 2:

The Moss Vale factory from above.

IMAGE 3:

Aerial

view of the Akashi factory in Japan.

“They bought the shares of the company so that

everything like ABNs and business names are completely

unchanged. They have a long term view of the market and

want to work closely with our key customers, suppliers and

employees to grow the business. The focus is very much

about leveraging Noritz’s technical capabilities to build

better and more competitive tanks in Australia and also to

introduce new and better water heaters.

“It’s a very exciting time and we’re thrilled that it coincides

with our 100 year anniversary in 2015.”

1

2

3

INDUSTRY MOVEMENTS