3 6

PLUMBING CONNECTION

AUTUMN 2015

with the addition of a 3000 tonne

copper alloy extrusion press and

integrated cold drawing equipment.

PRODUCT INNOVATIONS & A GLOBAL

APPROACH

In more recent times, Crane Copper

Tube developed a global reputation

as an innovative, dependable and

high-quality producer. The company

manufactured copper tube to

Australian, New Zealand, British,

European and American standards for:

∫ Water supply

∫ Drainage and sanitation

∫ Gas reticulation

∫ Refrigeration

∫ Heating and Air Conditioning

∫ Electrical componentry

∫ Automotive Instrumentation

∫ Medical gases

∫ General engineering

Its focus on the global market

received a boost in 2006, when

Crane Copper Tube partnered with

the German-made Viega Group to

release Viega Propress – a press-fit

joining system for copper tube – to the

Australian market.

In recognition of its world-class

manufacturing, Crane Copper Tube

held the third party accreditation

to AS/NZS ISO 9001:2000 quality

systems for production and

installation as well as Australian

Standards mark and other product

certification licences.

Further recognition of quality came

in 2005, when a number of employees

gained a Certificate III in Competitive

Manufacturing. This qualification

focused the company culture on

creating customer value.

PRESENT DAY

Parent company Fletcher Building

announced the closure of Crane Copper

Tube in September 2014 citing years of

unprofitability due to overcapacity of

copper tubing, increasing substitution

of copper tubing with other materials

such as plastic composites.

Fletcher Building Chief Executive

Mark Adamson said the decision to

cease trading was not made lightly.

“We would like to acknowledge all the

Crane Copper Tube employees whom

in recent years have been relentless

in their efforts to reduce operating

losses.”

Crane Copper Tube is currently

transitioning out of export trading.

Meanwhile, Fletcher Building has been

working with employees to help find

redeployment opportunities.

The Penrith site will remain in

Fletcher Building ownership once the

plant and other assets are sold or

removed. Mr Adamson thanked Crane

employees past and present for their

contribution to the business.

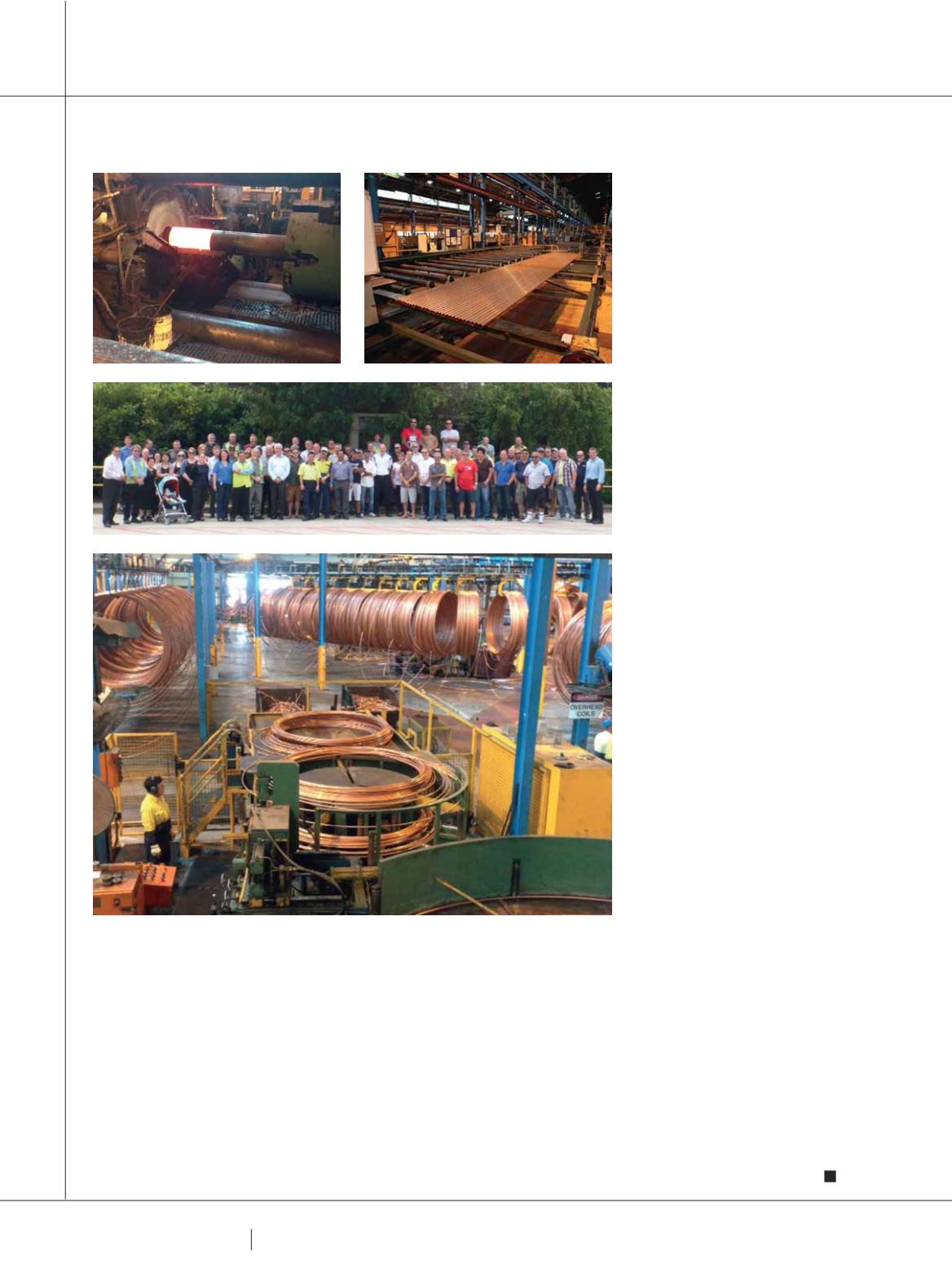

The Crane Copper Tube factory in Penrith ceased manufacturing and domestic

trading at the end of 2014 after nearly 150 years in operation. The closure marks

an end of a significant era in Australian manufacturing.

END OF AN ERA