74

ACROSS THE TRADES Winter 2022

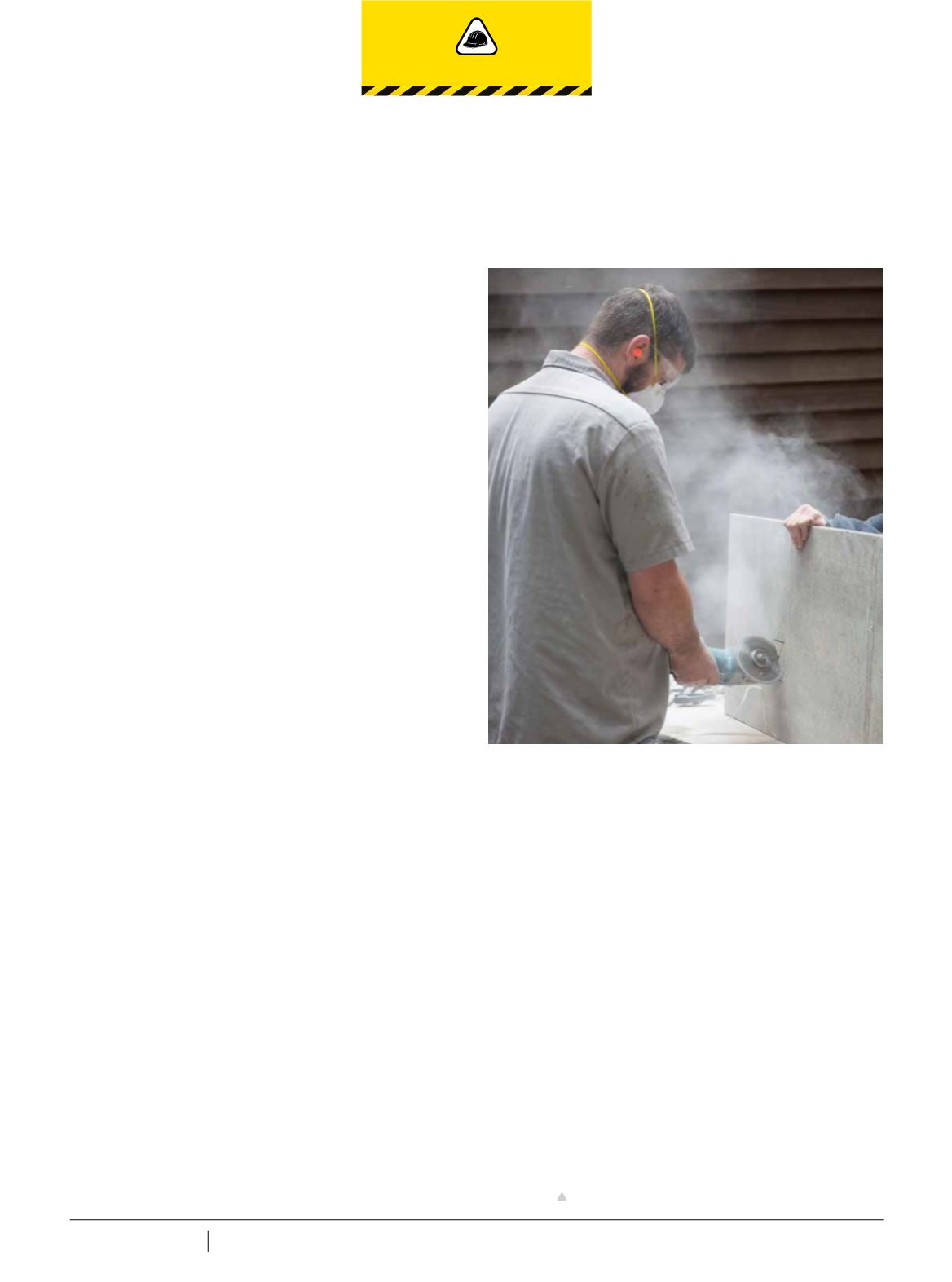

DAMPENING THE SILICA ISSUE

RESPIRABLE CRYSTALLINE SILICA (RCS) IS A MAJOR ISSUE IN THE BUILDING AND CONSTRUCTION INDUSTRY.

SEAN CARROLL

WRITES ABOUT WHAT ARTIBUS IS DOING TO TACKLE THE ISSUE ACROSS THE COUNTRY.

S

ilica, or more specifically, silica dust is a known hazard

that comes from some stone, rock, sand, gravel and clay.

It can be found when manipulating several common

materials like bricks, tiles, concrete and some plastic material.

Because of where it comes from, it’s critical for building and

construction workers to know about the risks associated with

it and steps to prevent the release of respirable crystalline

silica or silica dust.

Workers in engineered stone benchtop manufacturing,

finishing and installation are at particular risk, as this

comparatively new material contains up to 95% crystalline

silica, as distinct from natural stone’s crystalline silica

composition of 5%-50%.

The results are deadly as silica dust can lead to lung cancer,

silicosis, chronic obstructive pulmonary disease and kidney

disease. All states and territories across Australia have work

health and safety laws that explain duty of care for employers

and workers’ responsibilities.

Despite the abundance of caution and laws surrounding the

prevention of silica dust, it’s estimated that 230 Australians a

year develop lung cancer due to past exposure.

“In recent years, there have been stories around accelerated

cases of silicosis and lot of that has been emanating from

engineering, manufacturing and the energy industry,” Artibus

Innovation senior project officer Charles Donnelly says.

Artibus Innovation is a skills service organisation assisting

the National Construction Industry to develop training standards

around silica dust safety. These will be submitted to the

Australian Industry Skills Committee (AISC) for approval to Skills

Minsters and form part of the national construction training

package used by training organisations across Australia.

“After a growing number of cases, SafeWork NSW approached

the AISC and recommended that construction training packages

include dedicated training components around silica safety

because, at the moment, there are no units of competency in the

national training package that reference silica, although a number

of them do contain awareness of hazards, including silica.”

As of late 2021, the silica project has progressed through the

consultation process. It will produce four units of competency,

focused on knowledge, safe handling and risk management for

new entrants through to supervisors.

In Safe Work Australia’s guidelines for removing silica dust

in work, it says that companies can eliminate silica dust at the

source by eliminating the processes that generate dust.

For example:

∫

Adopting production processes that generate less dust - for

example any wet method is likely to generate less dust than

a dry one;

∫

Treating the dust at the point of generation, as this is more

effective than capturing airborne dust; and

∫

Treating the dust on its transmission path using dust

suppression techniques - for example water sprays,

chemical additives, local exhaust ventilation (LEV),

vacuum. If it is reasonably practicable, eliminate the silica

containing products from your workplace.

“Silica poses a very serious risk when it’s being worked with

in ways that are unsafe, especially with products that contain

higher concentrations of respirable crystalline silica like

engineered stone,” Charles explains.

“We’re seeing businesses conducting safer work practices

around silica and doing the right thing with regard to wet

cutting and wearing the appropriate respiratory protective

equipment and this awareness just wasn’t there 20 years ago.”

He adds that while the industry has come a long way,

there is still work to be done in terms of hazard awareness

and making sure that we eliminate silica-related deaths in

Australia.

It’s estimated that around 230 Australians a year

develop lung cancer due to past exposure to silica.

SAFETY