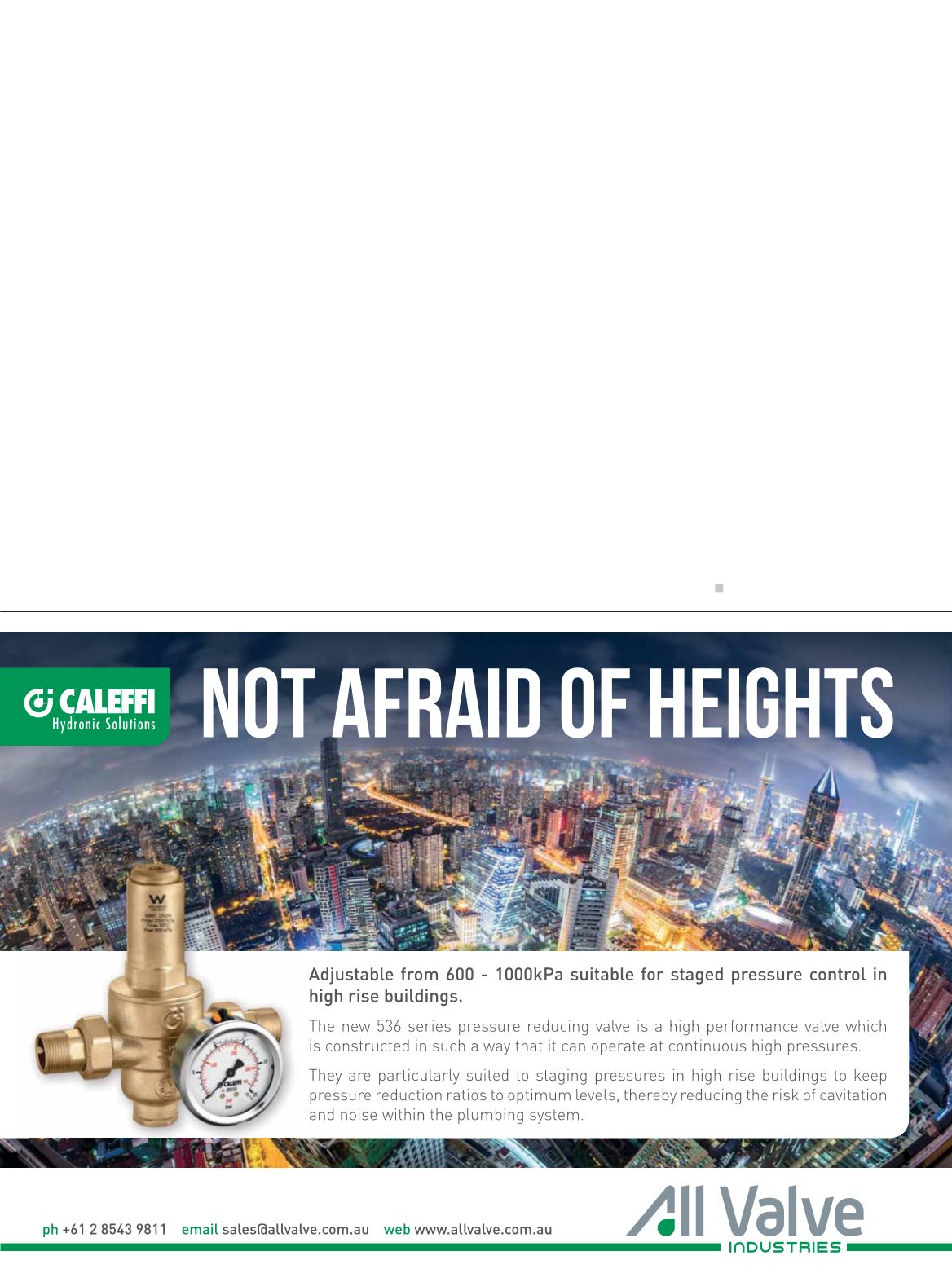

a direct acting pressure reduction valve

that would have the capacity to be an

off-the-shelf-product in the future.

The test rig used by Houman and his

team allowed for individual isolation of

the valves to create parallel and serial

configurations. Noise levels were also

recorded as part of the testing. All

Pumps Sales & Service developed a

pumping system to deliver a flow rate of

up to 5L/s at 1,800kPa.

Using a range of flow rates and

pressures, the test rig showed that a

single stage setup created significantly

higher noise levels than a double stage

arrangement. The report concludes

that “the dual stage pressure reduction

valve setup can perform at considerably

higher pressure ranges where the

conventional single stage designs fail to

deliver the required performance.”

For the high rise building in Sydney,

this means that a solution has been

found to manage pressure reduction

throughout the building without the

need for staged storage tanks. The

knock-on effects that David eluded to

can be minimised and noise levels within

the building would be maintained to

comply with the acoustic requirements

for the project.

“If we didn’t use this system,” says

David, “we would have to work out other

ways and means to reduce the pressure.

There are other design philosophies that

could have been adopted, but I think we

would have experienced more pipe work

that would not necessarily be cost-

effective.”

The system has been designed to

give a pressure reduction breakout on

alternate floors, with smaller systems

to cater for the next floor above.

“Using this configuration actually

makes it easier for the facilities

manager to maintain the system as

any pressure drops can be quickly

identified within a two floor location,”

says David. “We no longer need plant

rooms at regular intervals, and access

to the valves can be achieved through

a services cabinet. Ultimately it could

be wired up to a BMS system for

monitoring and alarm notifications.”

Plumbing contractor for the Sydney

apartment building, Andrew Khadi

owner of AK Plumbing, is confident that

Houman’s design will be successful.

“It is a new way of approaching

pressure reduction and it takes a bit

to follow the concept, but once you

understand it, it makes a lot of sense.”

says Andrew.

“On the odd floors, we have the

pressure reduction system Houman

has designed with low flow diversions to

the even floors. The system will be used

for the first 18 floors, after that, the

pressures aren’t such a problem.”

The building, due to be completed

by year’s end is well under way and the

building and plumbing contractors are

confident that the solution Houman

and his team found will be more than

satisfactory.