3 0

PLUMBING CONNECTION Summer 2017

development of the equestrian facility

further storage tanks were installed,

including 1.8 million litres of in-ground

tanks under the grand prix arena.

Further water storage is provided at

individual buildings typically of 100,000

– 200,000 litre capacities, plus a

number of dams around the paddocks to

supply the water troughs.

“Rainwater is collected from the

Colorbond roof on the covered arena – a

catchment area of 6,200m

2

, which is

potable. It is UV filtered and sterilised

for human consumption. Once full, those

tanks overflow into the non-potable

tanks which are used for stock drinking,

washing down the horses, cleaning the

stables and irrigation. Water from the

copper roofs is re-directed away from

potable sources.”

“The water collected from the copper

roofs is still compliant as potable

drinking water,” says Josh Pirotta,

services manager with Vital Design

Solutions. “As the roof ages, the salty

sea air will increase the level of copper

ions that are generated, to a point

that is no longer acceptable for human

consumption. So rather than face that

complication in five years, the decision

was made to re-direct that water to

non-potable storage.”

The whole system is pumped from

three main pumping stations, capable of

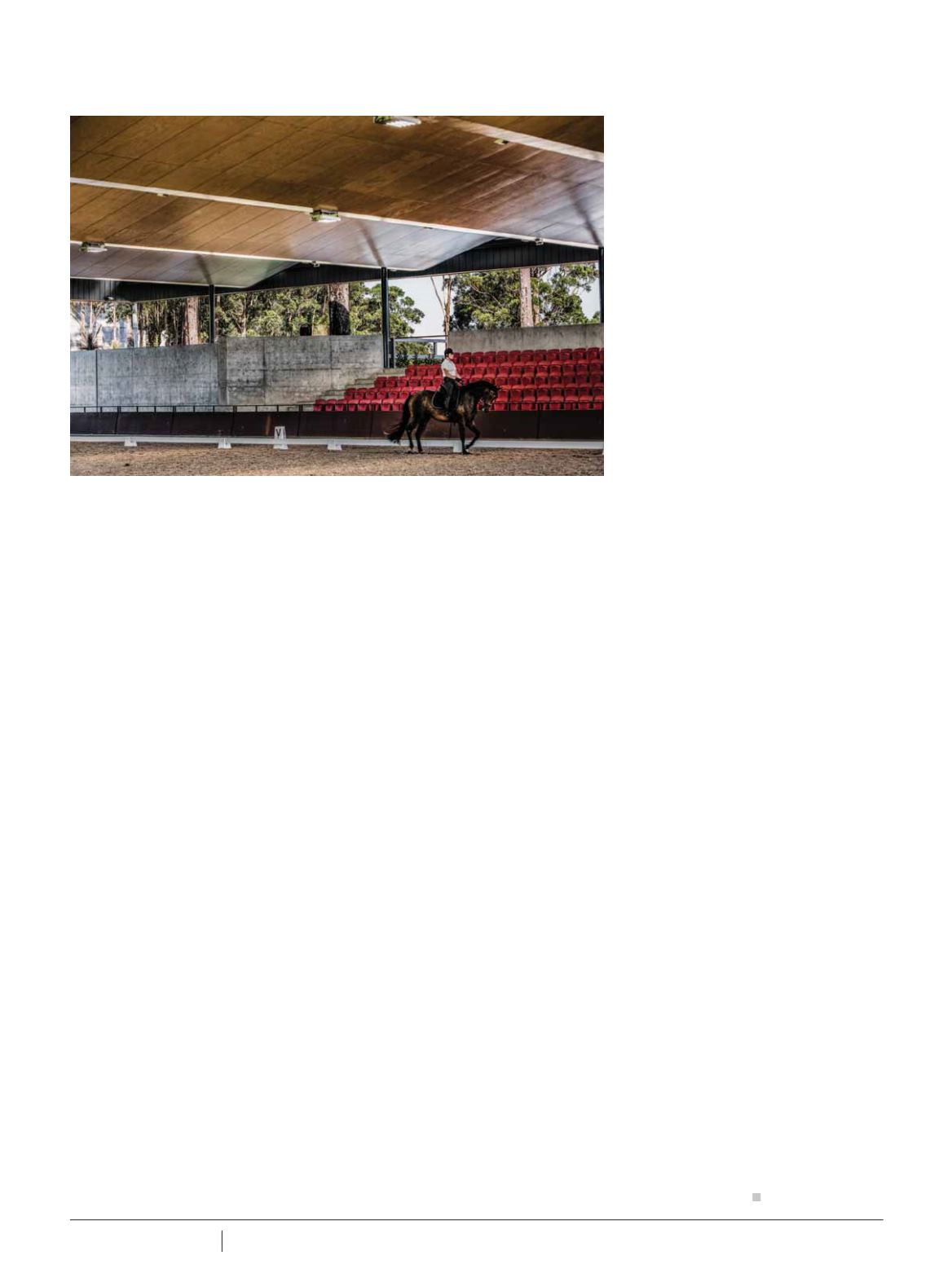

EQUESTRIAN CENTRE SPLENDOUR

The sawtooth roof design reduces shadows on the horses while providing an

optimal orientation for solar panels.

up to 1000 litres per minute, contained

within the basement as much for

aesthetics as for maintenance. In

essence, Vital Design Solutions opted

to run two independent pipe works for

potable and non-potable water. As a

consequence the biggest challenge

was to prevent cross-contamination

between the two streams.

To manage stormwater, there are

three systems in place. The first is

essentially the potable water from the

Colorbond roof, the second handles

the non-potable water from the

copper roofs, and the third is the civil

stormwater. The civil stormwater

collects water from surfaces such

as the roads, pathways and horse

washdown. It is then directed into a

bio-retention basin to improve the

water quality using vegetation before

it reaches the downstream water

systems at the bottom of the property.

Horse waste solids are recovered

and composted, broken down and

macerated for use as fertiliser. The

septic system for human waste is based

on an envirocycle system which aerates

waste in a similar concept to a small

tank system.

“Of the water used, about three-

quarters is non-potable for applications

such as garden irrigation and keeping

the grass in the holding yards green for

horse grazing,” says Josh. “We have

created an overflow daisy chain system

that means that tanks overflow into

the next. Pumps can then redirect that

water to wherever we need it around the

property. The addition of a bore means

we have another option to fill tanks

should we need it.”

Other water uses on site include

an evaporative misting system in

the stables to cool the horses in hot

weather, the training pool and hot

water systems. The forthcoming

160 stockyards will have their own

standalone water supply pipe work.

“We have designed the system to

be as low maintenance as possible,

including automatic backwashing

filtration if there is too much friction

across the filter, which reverses the

flow of water and discharges all the

wastewater out to a drain,” says Josh.

“With alarms, we can monitor what is

happening anywhere on site.”

THE NEXT PROJECT..

Since the facility opened, a further

160 stockyards are under construction

for eventers to house their horses for

equestrian events. The scale of this is

particularly challenging.

For the contractors, it requires

a new level of thinking. For Neil, he

will need to develop a cutting-edge

method of power supply – the grid

simply won’t cope. He estimates he will

need about 500kW of solar, 2MW of

stored energy (Lithium ion battery is

the current leader with conversations

underway with Magellan, Tesla and Flow

Technology) and 3MW of stand-by diesel

generation systems.

Josh needs to re-think how much

water will be needed for washdown,

drinking, cleaning and misting, and

what capacity hot water services. For

DJ, the lighting will still need to be in

keeping with architectural design but

particularly mindful of equine light

tolerances.

The project while challenging has

been rewarding for all the contractors

involved. For those in the equestrian

industry, the development of Willinga

Park as a world-class facility has been

a welcome addition to the international

circuit of eventing.