PLUMBING CONNECTION

SPRING 2016 59

The two questions most asked

regarding the installation of a backflow

preventer are as follows:

∫ do I need to support the device?

∫ what size drain do I need under the

RPZ?

The first is easy. It is good practice

to support the device so that its

weight doesn’t cause any strain on

the pipe work. Use a commonsense

approach and ensure the finished job is

commensurate with the professional

you are.

The second is much more difficult.

All device manufacturers provide

information on the discharge volumes

that RPZs will dump at various

pressures. Devices will dump water for

a number of reasons. One is pressure

fluctuations. This will cause the device

to spit water from the relief vent and

often will not cause more than a minor

inconvenience. Another is the device

will empty all the water from within the

valve should a negative supply incident

occur. This can be a large volume

depending on the size of the device;

15mm may be a cup full, 250mm will

be a bucket or more. The other reason

is a massive failure whereby through

either the head pressure within the

piping system or a ring main feed, the

device goes fully open and discharges

continually at full back pressure.

This is where the drain size is

critical and could mean the difference

between an inconvenience and a

large clean up cost and potential

insurance claim/litigation case. Your

customer expects the designer and the

installer to understand the operation

and potential issues so ensure you

know what the device manufacturer

recommends for their device.

Ensure you read the installation

instructions supplied with the

valves or ask your supplier for some

training. Ongoing skills based training

and development can assist with

minimising the chance of unexpected

pain and suffering.

Peter McLennan has been involved

with Backflow Prevention in Australia

since the late 1980s, is the President

of the Backflow Prevention Association

of Australia Inc., and Secretary of the

Backflow Prevention Association of

Australia Inc. Queensland Chapter.

Contact:

Visit

www.bpaa.org.auto find out more

about how the Backflow Prevention

Association of Australia Inc. can help

you understand cross connection

control and backflow prevention.

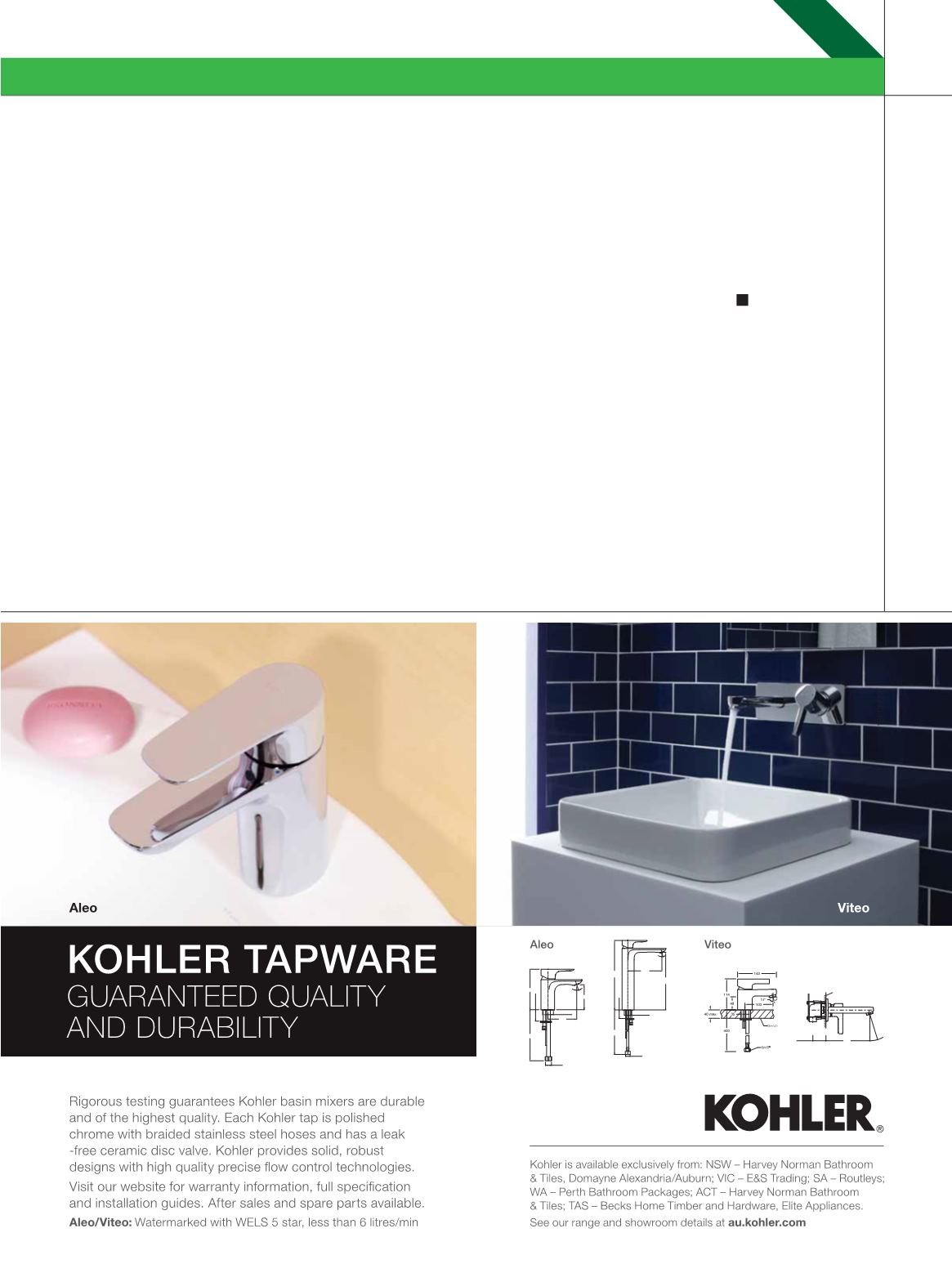

G 1/2”

Ø31~Ø37

100

18º

142

88

40Max.

450

Ø31~Ø37

159

14º

G1/2˝

323

268

40Max.

360

48.5~58.5

163

17°

Finishedwall