5 8

PLUMBING CONNECTION

SPRING 2016

INSTALLING BACKFLOWPREVENTERS

W

ith the use and installation of

backflow prevention devices

being commonplace now

since the mid-90s, you’d think the

industry would have a good handle on

the installation requirements and the

hydraulic aspects of how they work.

However, based on some recent and

recurring issues I’ve encountered, it

seems that this may not be the case.

HYDRAULICS

Backflow prevention devices are very

simple mechanical valves that stop the

reversal of flow of drinking water. Each

device is marked with the direction of

flow as they can only operate in one

direction.

The backflow prevention device uses

force-closed, spring-loaded check

modules that close when the incoming

water pressure drops below the spring

tension setting. The very fact that the

incoming water has to overpower a

spring means there will be a pressure

loss across the check valve. The degree

of this pressure loss will depend on the

type of device installed.

The Double Check Valve (DCV) has

two independently operating check

valves within the same body. To

comply with the Australian Standards

the spring settings must exceed a

differential across each check valve

of 7Kpa. This means the minimum

pressure drop across a DCV should

be 14Kpa. In reality, 14Kpa is not

achievable due to the tolerances in

springs and the flow passages through

a backflow preventer. Experience

indicates that a DCV has a pressure

drop in the vicinity of 25Kpa, but this

also depends on the manufacturer and

the age of the device as springs tend to

go soft over time.

The Reduced Pressure Zone device

(RPZ) also has two independently

operating check valves within the same

body but has a differential pressure

relief valve that opens to atmosphere

so that water will be drained from the

device if a backflow incident occurs.

To ensure the relief valve operates

as it should, the spring tensions in the

checks must be different enough to

provide a safety margin, otherwise

the device would continually drop

water from the vent due to supply

main pressure fluctuations. This extra

safety comes at the expense of a

higher pressure drop across the device

as the spring tension on the first check

must exceed 35Kpa and the tension

on the second check must exceed

7Kpa. Again, experience shows that

this 42Kpa is not achievable and the

pressure drop across an RPZ is more

likely to be above 65Kpa.

Protection of the drinking water

comes at the expense of the available

pressure, but a mechanical device

is still often a better option than a

complete break and repressurisation.

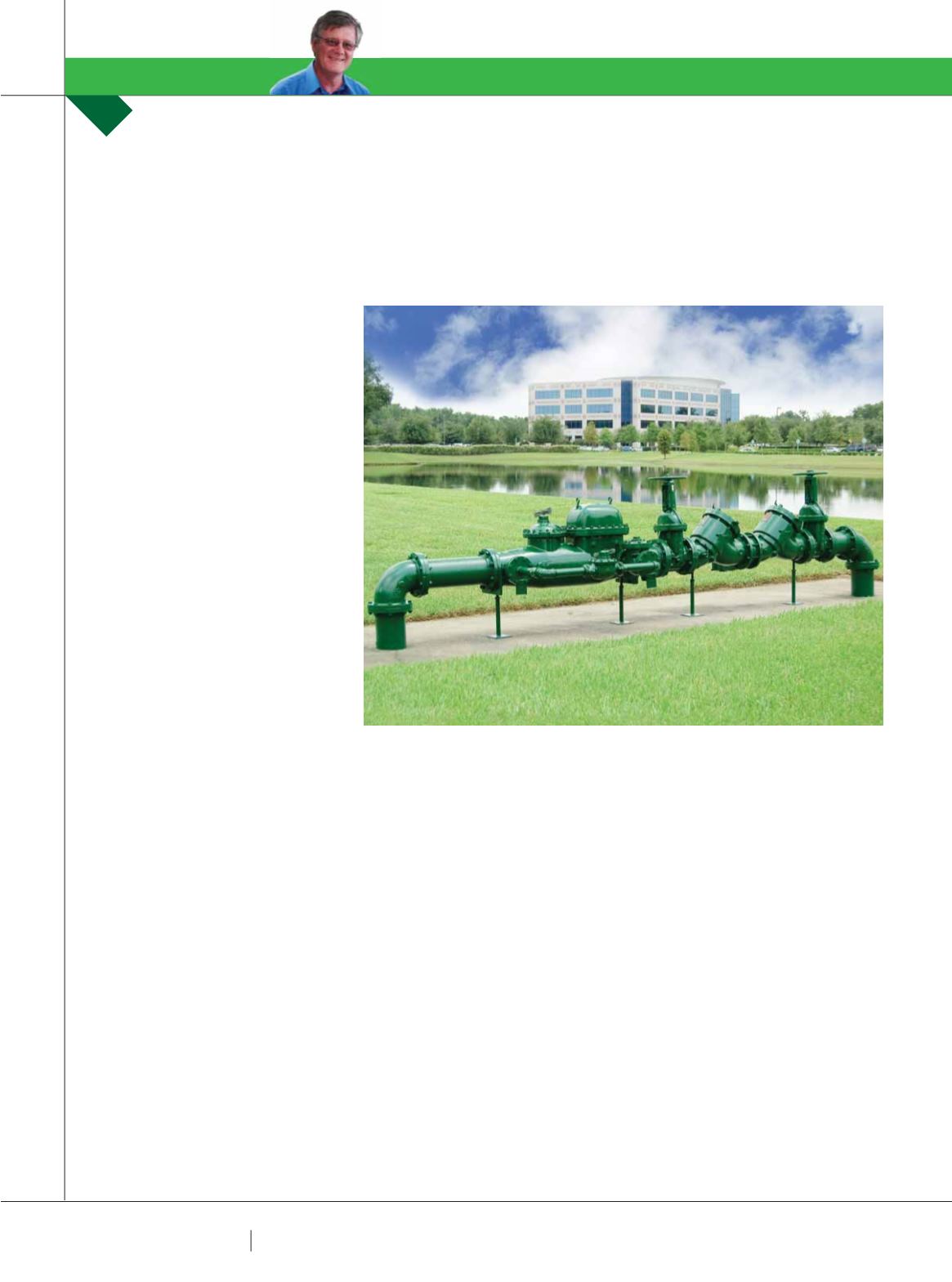

INSTALLATION GUIDELINES

The RPZ is only approved for

horizontal installation. This is because

the vent to drain the water away must

be the lowest point of the installation

and this cannot be guaranteed in a

vertical installation.

The DCV can be installed in both

vertical and horizontal applications

as long as there is adequate spacing

around the device for maintenance,

testing and repair.

PETER MCLENNAN

DISPELS SOME MYTHS SURROUNDING THE TWO MAIN BACKFLOW PREVENTION DEVICES SEEN

TODAY: THE REDUCED PRESSURE ZONE DEVICE (RPZ) AND THE DOUBLE CHECK VALVE (DCV).

BACKFLOW PREVENTION

PETER MCLENNAN

It is good practice to support the device so that its weight doesn’t cause any

strain on the pipe work.