8 4

PLUMBING CONNECTION

SPRING 2015

Until March 2014 Victoria and New South Wales were still

running with AS 5601–2004 as neither state accepted AS/

NZS 5601–2010.

There is a glaring discrepancy in what was Clause 5.2.5,

Manufacturers’ instructions for installation, in the 2004

version of the Standard where it stated: “Appliances shall be

installed in accordance with manufacturers’ instructions.”

No reference was made to the Standard in that clause

as is now required in the 2010 or 2013 editions of the gas

installation Standard.

The way the clause is written now means the plumber/

gasfitter is the loser all the way. Manufacturers could claim

that installers did not follow the product instructions, and

the technical regulator could say that installers did not

follow the Standard.

Years ago there was clear direction, as in the 2004

Standard. You have to wonder who comes up with clauses

that go around in circles.

At the former Gas & Fuel Corporation in Victoria, I supervised

a small group of gasfitters who inspected appliances for

approval and certification. Any installation manual submitted

with such contradictions would have gone back to the

manufacturer for rewriting. The appliance would not have been

given approval until the documentation was all correct.

Now, we have a Standard that allows manufacturers to

have a bit each way.

The second sentence of Clause 6.2.2 in the latest

Standard is similar to that in the 2004 and 2010 editions.

“Where there is any conflict between the manufacturer’s

installation instructions and the requirements of this

Standard, the matter shall be referred to, In Australia, to the

Technical Regulator.”

It helps to protect installers, as they could get a defined

ruling on what should apply if there were differences.

From what I understand, the technical regulators in each

state and territory sanction the operation of certifying

bodies. I wonder how often they carry out audits of these

companies to ensure that testing of individual appliances is

carried out according to the Standards and documentation

is concise and easily interpreted.

We need to obtain the best for the industry and, crucially,

for the customer. So who is reviewing manufacturers’

documentation to ensure that instructions are practical and

installers can carry out the work safely and efficiently?

It is not the responsibility of installers to determine

what is right or wrong in the installation instructions.

Discrepancies should be resolved when the manual is

being prepared. I have looked at just a few pages of this

particular installation manual, and there are others in a

similar state.

Australia used to have one certification body, but now

there are four competing against each other. Competition

is supposed to bring improvement, not uncertainty and

confusion.

One of the most important pieces of information on a gas

appliance is the badge or data plate. Among other things, it

shows the approval number, gas operating pressure and gas

consumption per hour.

While reviewing a set of instructions for an appliance

recently, I discovered that the unit had to be partly

dismantled to find the plate.

It was necessary to remove the front glass panel, any fuel

bed media, the burners and firebox base to gain access to

the plate – which was under another access panel.

GAS MATTERS

ROGER LAMBIE

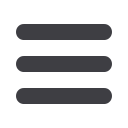

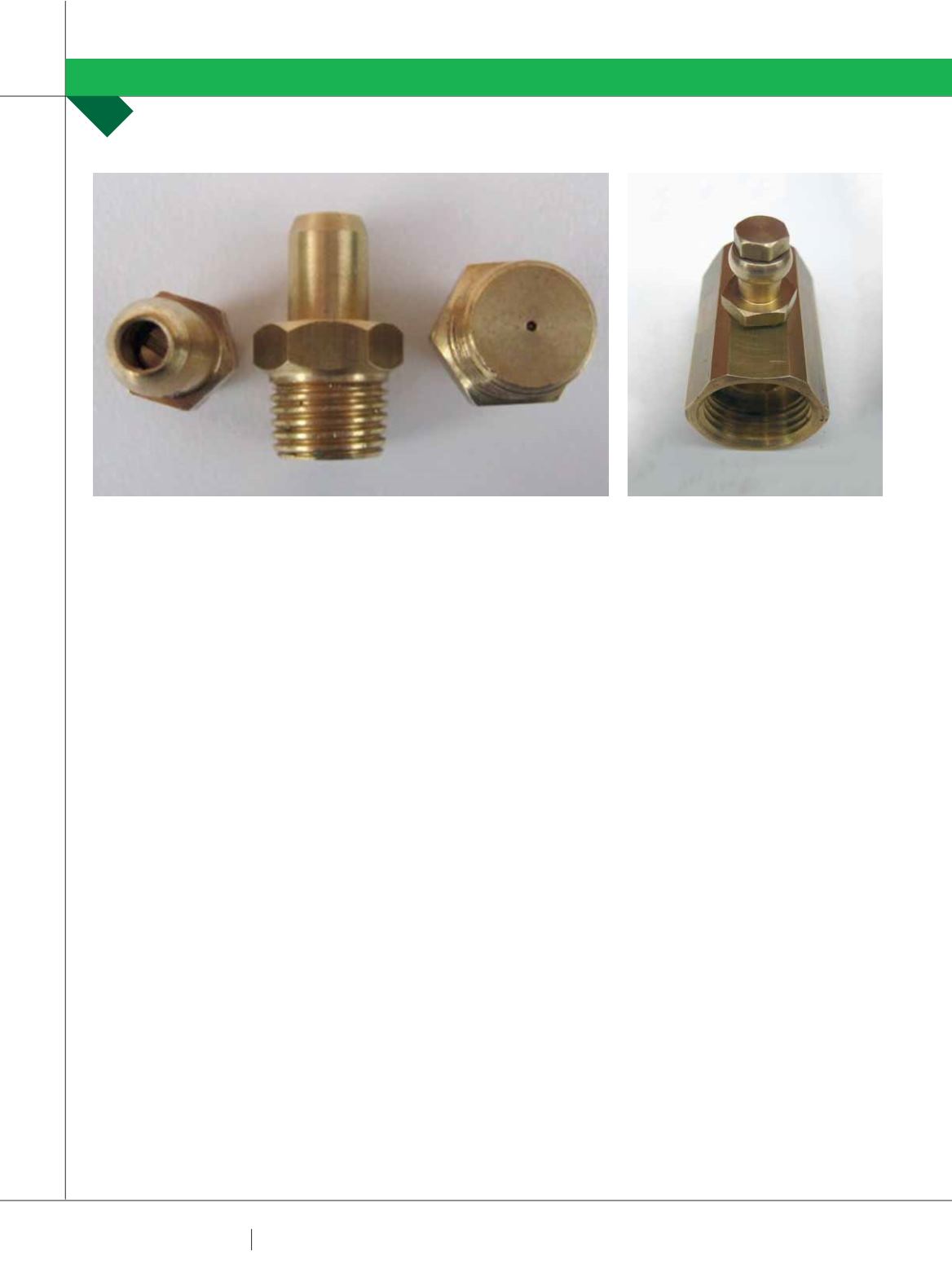

Where a permanent pressure gauge is fitted, a provision to fit an alternative test point shall be provided. Where pressures

exceed 7kPa, pressure test points shall be of the self-sealing type.