6 4

PLUMBING CONNECTION

WINTER 2016

THE PERFECT MATCH

U

ltra-modern toilet pans

are almost unrecognisable

from their predecessors in

all facets: looks, functionality and

performance. Toilet pans are now able

to perform an effective flush using

far less water thanks to the design

advancements in shape and size of the

flush bowl and the profile in which the

water flows through. The drawback

of these cleverly engineered flush

profiles is that they generally have a

higher susceptibility to compromised

performance when set up with

incorrectly matched flushing devices.

Four Star WELS rated toilet pans are

designed for low water consumption,

with only 4.5 litres of water coming

from a full flush. Because the volume

of water is quite small, the pan must

efficiently clear the contents of the

bowl quickly where there is a residual

amount of water following the waste to

carry it to the sewerage network. For

a toilet pan to operate at its maximum

efficiency it requires water to be

delivered to it at the rate and pressure

that it was initially designed and tested

for.

The flow rate and pressure changes

the way water is dispersed around the

rim to correctly cascade down into

the bowl in the right locations. If not

correct, the pan’s performance can

be severely affected. Insufficient flow

usually means that the front of the rim

is starved of water, and aggressive

flow often results in water splashing

onto the bathroom floor. New style

rimless toilet pans can be particularly

sensitive to incorrect flush conditions.

Flushing pressures and rates are

controlled by the cistern, (or electronic

valve) that the toilet pan has been

matched with. For close coupled

suites, the cistern is mounted on top of

the pan and would have been perfectly

matched by the manufacturer during

design. The matching task increases

in complexity for wall faced, or wall

mounted toilets which need to be

connected to a separate flushing

device, typically from a third party

manufacturer.

Historically a discharge flow rate

of 1.4 litres per second has been the

number that cistern manufacturers

have worked to. More often than not,

this flow rate is still adequate and

suitable for a lot of pans on the market.

In more recent times the evolution

of bathroom design with greater

emphasis on beauty and practicality

in high density urban developments

has seen a shift in toilet pan design.

Smaller bathrooms promote the

demand for smaller wall faced or wall

mounted pans using the space in the

wall to house the matched flushing

device.

Rimless toilets, new to our market,

have a narrower tolerance in flow

delivery requirements than a typical

boxed rim toilet pan. Such pans

have a lower margin for error and

BATHROOM PRODUCTS HAVE COME A LONG WAY OVER THE PAST NUMBER OF YEARS AND THE HUMBLE TOILET PAN

HAS SEEN SOME OF THE LARGEST DEVELOPMENTS OF ALL.

TERRY NGUYEN

EXPLAINS THAT WHEN IT COMES TO

TOILETS PANS AND FLUSHING SIZES, ONE SIZE DOES NOT FIT ALL AND FINDING THE PERFECT MATCH IS A MUST.

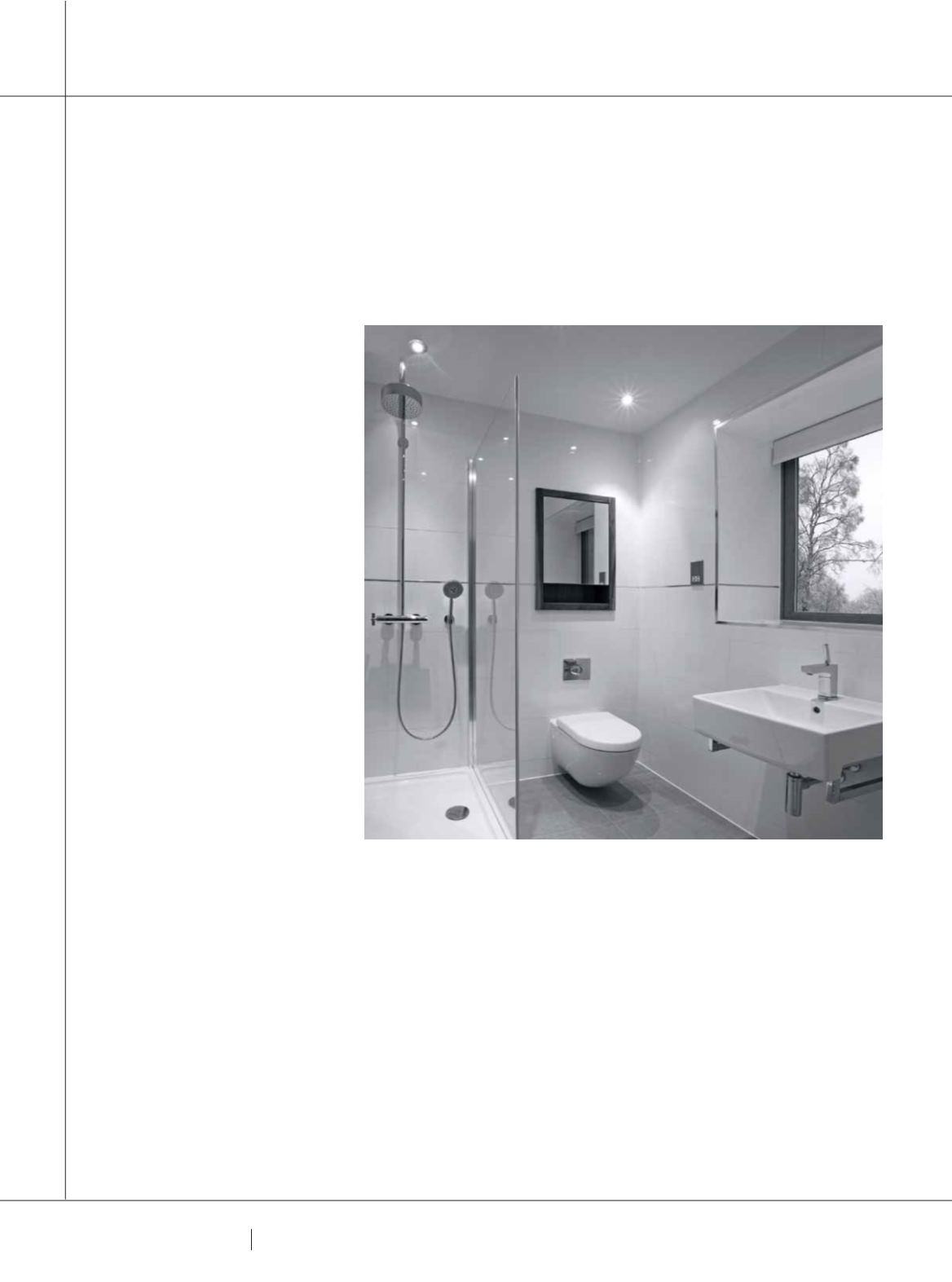

Toilet pans matched with an incorrec flushing device can cause many issues.

PROVE STANDARDS