9 0

PLUMBING CONNECTION

WINTER 2015

school. Coming from the Australian

environment of OHS madness, the

conditions in the factory can be

confronting but the company is

gradually improving the life of the

worker. Changing the worker culture

to readily accept wearing safety gear

is as much the issue as anything. The

Indian Cricket team may have to wear

fluorescent safety vests before you’ll

see them popular in this part of the

world.

India is a low-cost producer and

with an average worker salary in this

Hindware plant of ~$2,500 a year, there

is no rush to automate tasks that are

better handled with a skilled potters

care and understanding. However, with

the size of production runs growing,

the company will in the future consider

more modern casting facilities and

robotics. The challenge for business

in these older parts of the city is the

erratic power supply which can go

offline 8-10 times a day. Thus, triple

backup of generators is necessary.

My hosts, the plant CEO and

managers were most hospitable on the

day and very proud of their company

and its achievements.

The next day I took a similar ride

into the suburbs in another direction

to visit the Hindware tapware facility

at Bhiwadi. Hindware has been making

taps for many years but are looking

to significantly grow the business

towards 10 million units in coming

years. This was a new green-field site in

a commercial zone that has improved

infrastructure – gas, electricity and

water, though there is still some-way to

go with roads. The tapware plant is only

partly built out at this stage. Current

production is running on one floor but

there are plans to expand to three other

floors as the market grows.

Well aware that it needs modern

environmental practices, the new

India is building such plants to ensure

it maintains a healthy position with

global competitors.

The management team was highly

educated and use modern western

techniques to continuously improve

quality and output. Though a western

visitor might think the factory looks

only partly finished, the culture of

India is to get in and start producing as

that will create employment. There’s

no need to wait for the niceties.

Because of the access to relatively

low-cost labour, the one thing you

do notice is the lack of materials

handling equipment. There are plenty

of available arms and hands and

there’s no danger of a fork lift running

employees down from behind!

In talking later with Rajendra

Somany, I got the idea that Indian

business was confidently moving

forward under their business-centric

Prime Minister Modi’s agenda.

Hindware has plans afoot to take its

brand to global customers, including

this region. Some Hindware product

was sold in Australia a number of years

back under an import arrangement,

PLUMBING ABROAD

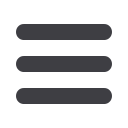

TOP:

Hand polishing is labour intensive, no matter where in the world tapware

is manufactured.

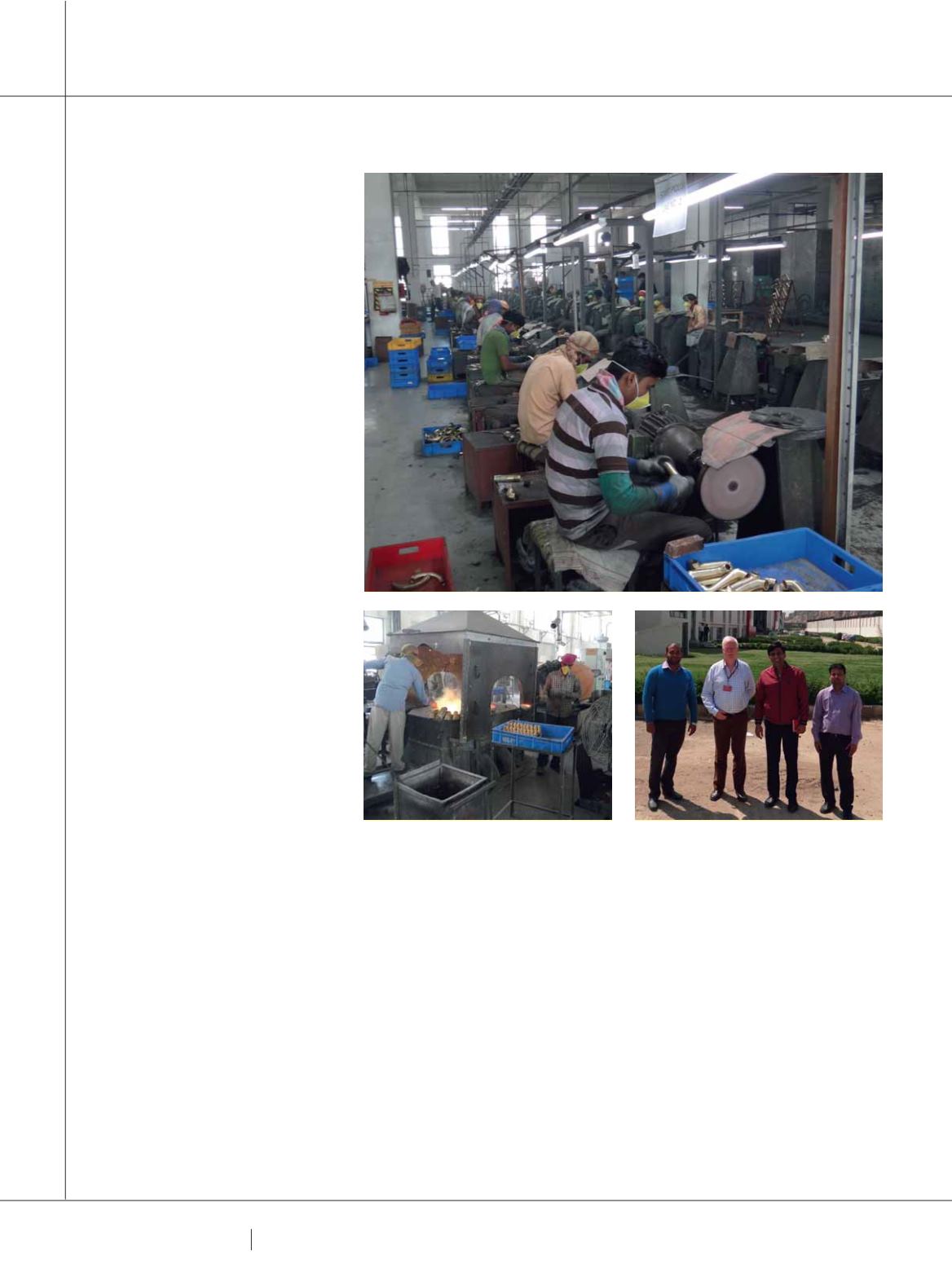

LEFT:

In the foundry, molten brass is ladled out and poured

into ingots.

RIGHT:

L to R:

Mr. Rakesh Yadav-Assistant Manager, Industrial

Engineering; Jeff Patchell; Mr. Ajay Jain- Vice President, Administration; Mr.

Narendra Kumar Gautam-Deputy Manager, Quality Assurance.