4 0

PLUMBING CONNECTION

WINTER 2015

in the hot water reticulation system are maintained to an

absolute minimum, the DOH nominates a minimum of 10

lineal meters or 2 litres of draw off. In our hydraulic designs

engineers normally aim to have even less draw off than this.”

KEEP IT CLEAN

The last tactic in the fight against biofilm is keeping the

water system clean. This can begin even before the water

has entered the building.

“Site filtration, UV disinfection and chlorination are used

and advised methods for incoming cold water supplies to

reduce the risk of breeding legionella and pseudomonas,”

Antonio states.

Once the system is installed, regular maintenance is

needed.

“Storage tanks should be inspected regularly and cleaned

and disinfected annually,” advises Antonio. “A close eye also

needs to be kept on automatic backwash filters and bag

filtration systems.”

The right materials can help keep the inside surfaces of

the plumbing fittings clean. Rada aims to eliminate plastics

and reduce the use of elastomers in their new range, as both

of these materials give bacteria a place to live and often

provide a food source.

“If you can optimise the product to make it entirely of

metal, you’d be doing a good job,” Kevin says. “Brass and

copper are the favoured materials because they have

antimicrobial properties.”

Copper and brass are more expensive, but with the

shrinking of the taps mentioned above, the amount of

materials needed (and the cost) is also reduced.

Perhaps the most challenging and labour intensive

method of keeping it clean is thermal disinfection. Even with

a thorough treatment system, legionella and pseudomonas

can make their way into a building’s water system – thermal

disinfection is one method of killing these invaders.

The first challenge is keeping the water hot enough to kill

bacteria. As discussed above, many of Australia’s hot water

systems are actually warm water systems and not capable

of maintaining the temperature required: at least 60°C, but

preferably above 70°C.

The second challenge is to avoid scalding anyone during

the process.

“At the moment, it seems like a very manual process,”

Peter explains. “Maintenance staff stand in front of the

shower and physically flush the system.”

There are moves to automate the system and have it

running when it’s unlikely anyone will be using those outlets

– for example, in the early hours of the morning. But in many

of these facilities, it’s impossible to ensure no one will be

using the outlet. Peter gives the example of an older lady

with dementia who might decide to have a shower at two

o’clock in the morning.

The Rada range has been designed to offer automated duty

flushing, but the risks presented by thermal disinfection require

a maintenance engineer to be present. Should they leave the

tap unattended before the cycle has finished, a safety feature

will terminate the disinfection cycle, if the tap’s sensor senses

a person’s hands approaching. But this is high-end technology

which will retrofit into most situations as long as a power cable

can be located near to the tap or shower.

THE ONGOING PUZZLE

The battle against bacteria is certainly an ongoing one. As

bacteria develop resistance to different antibiotics and adapt

to new environments, we will need to change our defences to

match. Plumbers and hydraulic engineers have many weapons

at their disposal; it’s a matter of finding the right ones for the

situation. As Antonio states, “It is crucial that pre-filtration

and treatment systems that are selected suit the end users’

needs and methods, otherwise they just don’t get used.”

The same could certainly be said for the water distribution

systems and other end use products. The tactics used must

suit each individual battleground.

Reliance Worldwide Australia

rwc.com/auThornthwaite Technologies, distributors of Rada

thornthwaite.com.auWood & Grieve Engineers

wge.com.auINFECTION CONTROL

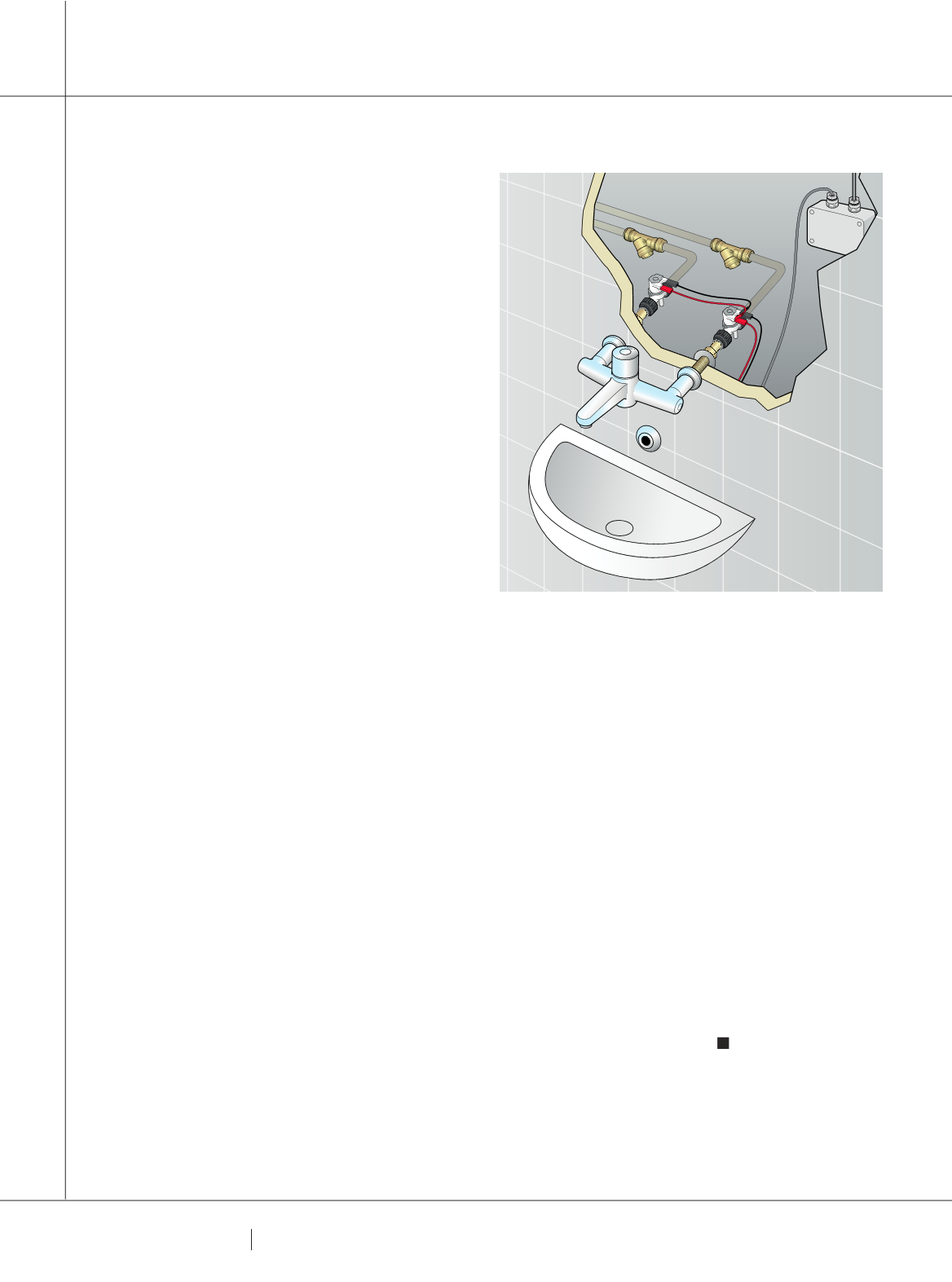

A TMV installation depicting the hot and cold water inlets.