1 0 2

PLUMBING CONNECTION

WINTER 2015

It was clear that PE-X provided the

most cost effective solution for the

small diameter roughin. Copper Press-

Fit provided the cheapest option for

use in DCW and DHW in the DN15-50

sizes. Using brazed copper plumbing

fittings for diameters greater than

DN50 whilst slower than using press-

fittings was found to be the most cost

effective due to their lower material

cost used in this estimate.

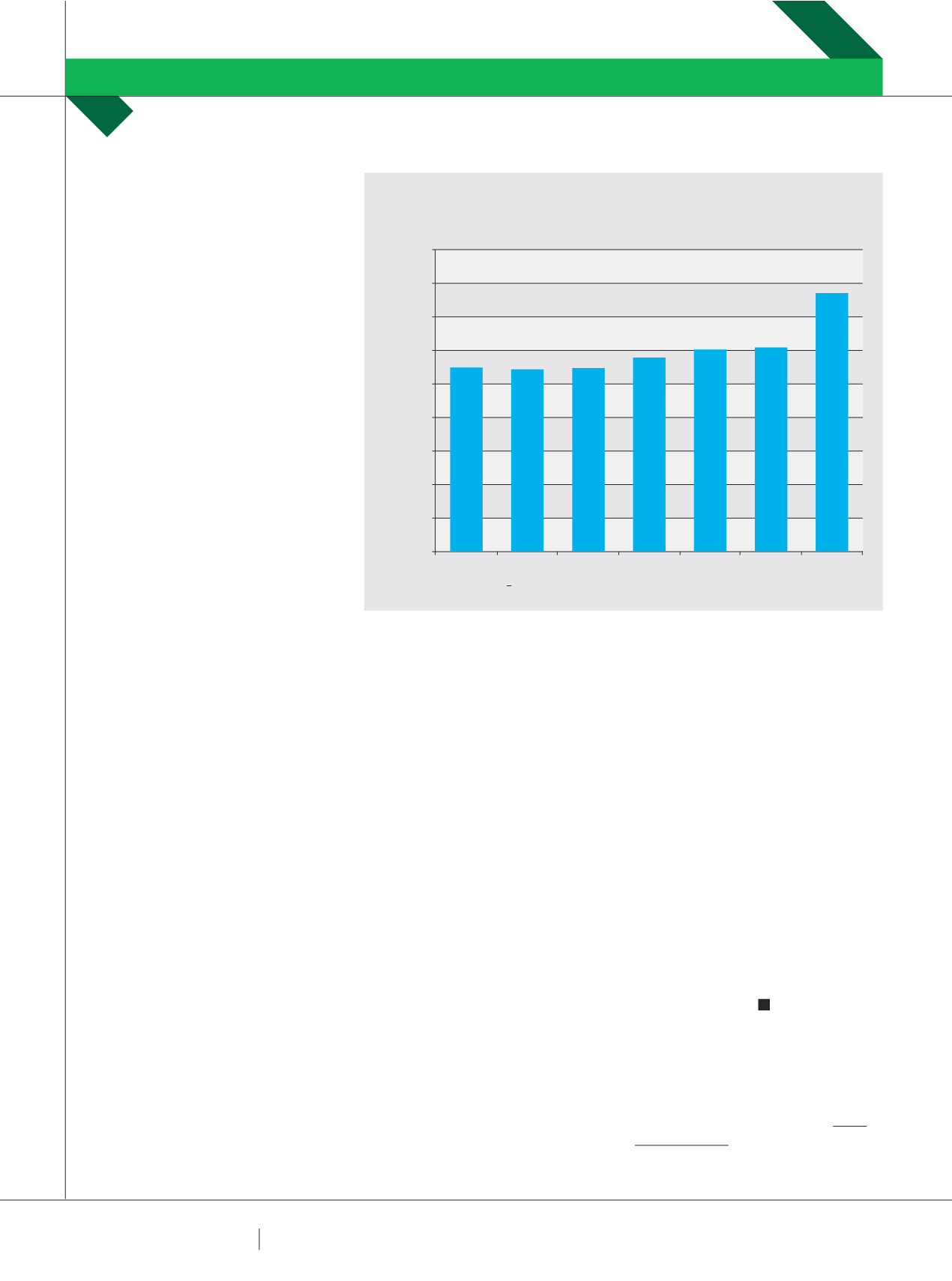

TIME IS MONEY

Many installations have time

constraints; however the ability to

allocate labour resources on to the

next project as quickly as possible

should also be a key consideration

in piping system selection. Figure 2

shows the installation time required

for a number of piping system

combinations.

The SX Estimate comparison study

found that the combination of using

PE-X for the rough in and Copper

Press-Fit for all sizes in DCW and

DHW plumbing provides the fastest

installation. In this estimate Copper

press-fit was found to be 14% faster

than using copper CTS fittings and

anecdotal market feedback is that

copper press-fit installations have

been found to be up to 30% faster than

CTS fittings.

SCOPING IT OUT

Cost is not the only factor when

selecting piping materials and care

needs to be taken to choose the

most appropriate material for the

environment where the plumbing

system is installed. Some things that

need to be considered include:

∫ The products you use should comply

with Australian Standards and

ideally be manufactured by a quality

endorsed manufacturer

∫ Use a reputable, proven quality

product with local support and

expertise.

∫ The correct tools for the job-many

systems require proprietary tools to

make a joint and these can add costs

or require new skills

∫ Solar hot water systems are

becoming more common with the

high temperatures experienced

within the industry and metallic pipe

systems are required in accordance

with AS3500.4. Pipe jointing

methods should be selected for the

temperature ratings of the fittings.

∫ Historic or sensitive buildings may

require flame free installations.

∫ UV stabilised materials should be

used when installed in areas of

direct sunlight & this can impact

choice between metallic pipes and

plastic pipes.

∫ Multi story buildings require higher

water pressures to get the water

to the top of the building and to

increase the pressure zones with

a building. The piping material/

pressure ratings are critical when

selecting a pipe system.

∫ Flow velocity within a pipe will

determine the pipe size to ensure

material longevity and prevent

system noise.

∫ Heated water circulating systems

require the pipe system material to

withstand the constant temperature

of the water without risk of failure.

The cost of plumbing is a significant

component of any building and this

analysis has shown that one piping/

fitting system may not be the best

selection for the specific sites

requirements.

As a summary the following pipe

systems will provide the most cost

effective total installation cost to the

plumber while ensuring a reliable and

proven installation.

1. Rough ins - PE-X

2. Domestic Cold Water – Copper

Press-Fit <50mm & CTS for >65mm

pipe sizes or Full CTS

3. Domestic Hot Water – Copper Press-

Fit <50mm & CTS for >65mm pipe

sizes or Full CTS

For further information on hydraulic

piping design considerations refer

to the recently published Hydraulic

Services Design Guide which is

downloadable free of charge at www.

copper.com.au. This is a 200 page

manual for use by hydraulic designers

and contractors.

COPPER CONNECTION

JOHN FENNELL

FIGURE 2

HOURS

INSTALLED TIME (HOURS)

-

500

1,000

1,500

2,000

2,500

3,000

3,500

4,000

4,500

PE-X Roughin

Cu PressFit

25-100mm

PE-X Roughin

Cu PressFit

< 50mm Cu

CTS>50mm

PE-X Roughin

Stainless

PressFit

25-100mm

PE-X Roughin

Cu PressFit

25-100mm

Full Cu

PressFit

15-100mm

Full Cu CTS

15-100mm

PE-X Roughin

PP-R (DCW)

Cu CTS (DHW)