3 8

PLUMBING CONNECTION Winter 2022

Other electrical hazards include

using faulty appliances and leads,

digging up underground electrical

cables or sticking metallic items into

or near overhead mains. These types

of incidents can also result in the

electrocution of plumbers and water

authority technicians.

DEATHS & INJURIES

The following are some examples of

the tragic circumstances that can

occur if the ‘live’ waterpipe hazard isn’t

effectively managed:

The last water authority technician

that was electrocuted (the injury or

killing of someone by electric shock)

that I am aware of occurred in Sydney

in 2005. Allegedly, he was repairing a

water service at a residential property

using a bridging lead, but it wasn’t

connected one end or had been knocked

off during work.

A plumber was electrocuted in

Yennora in Sydney’s west in 2009 who

had been cutting a waterpipe without

a bridging conductor or any other

controls.

An apprentice was electrocuted

in 2008 when he tried to rescue his

boss, who had been cutting a metallic

waterpipe. The boss survived but not

the apprentice.

Denishar Woods was 11 years old

when she touched a ‘live’ metallic

tap in 2018. Her heart went into

ventricular fibrillation, and she suffered

permanent and debilitating brain

damage. Whilst Denishar isn’t a plumber

or water authority technician, the same

thing could have happened to these

tradies.

There are many examples of deaths

and severe injuries from faulty

appliances and metallic objects.

CONTRIBUTING FACTOR & CAUSE

Prior to a change in the electrical

‘Wiring Rules’ in 1979, electrical

installations generally used the metallic

waterpipes as the earth electrode.

From 1979 onwards, an earth electrode

driven in the ground has been used to

provide a return path for the neutral

current should a neutral connection

burn off. Additionally, metallic

waterpipes have still been required to

be connected to the electrical earthing

system.

If replacing the metallic water service

into a property, then an electrician will

be needed to install an earth electrode if

one is not already installed.

CONTROL MEASURES

Control measures include:

∫ have the electrical installation

checked by a competent electrician or

electrical inspector;

∫ use non-contact voltage testers for

an initial voltage test;

∫ voltage monitors connected to the

metallic waterpipes for the duration

of the work;

∫ screw-up bridging conductors;

∫ wear insulated gloves for the duration

of the job;

∫ turn off all electrical load;

∫ stop work on metallic waterpipes

during storms;

∫ dial before digging;

∫ look up and live; and

∫ use tested and tagged electrical

appliances.

ADDITIONALLY

Policies, procedures, and safe work

method statements will be needed to

ensure the safety of workers.

Training in the procedures and

management of the electrical hazard

will be essential.

CONCLUSIONS

Working on metallic waterpipes can

result in catastrophic incidents if the

electrical hazard hasn’t been managed

properly. Additionally, anyone receiving

an electric shock, no matter how small,

should seek medical attention.

Equipment, procedures and training

are also important in managing the

hazard. Companies like PowerLogic can

help in this regard.

Chris Halliday MElecPowEng,

GradDipMgt, AdvDipOHS,

CertTAA is Director of

Electrical Consulting and

Training Pty Ltd, trading as

PowerLogic, in NSW. Visit

www.powerlogic.com.auELECTROCUTION -

CHRIS HALLIDAY

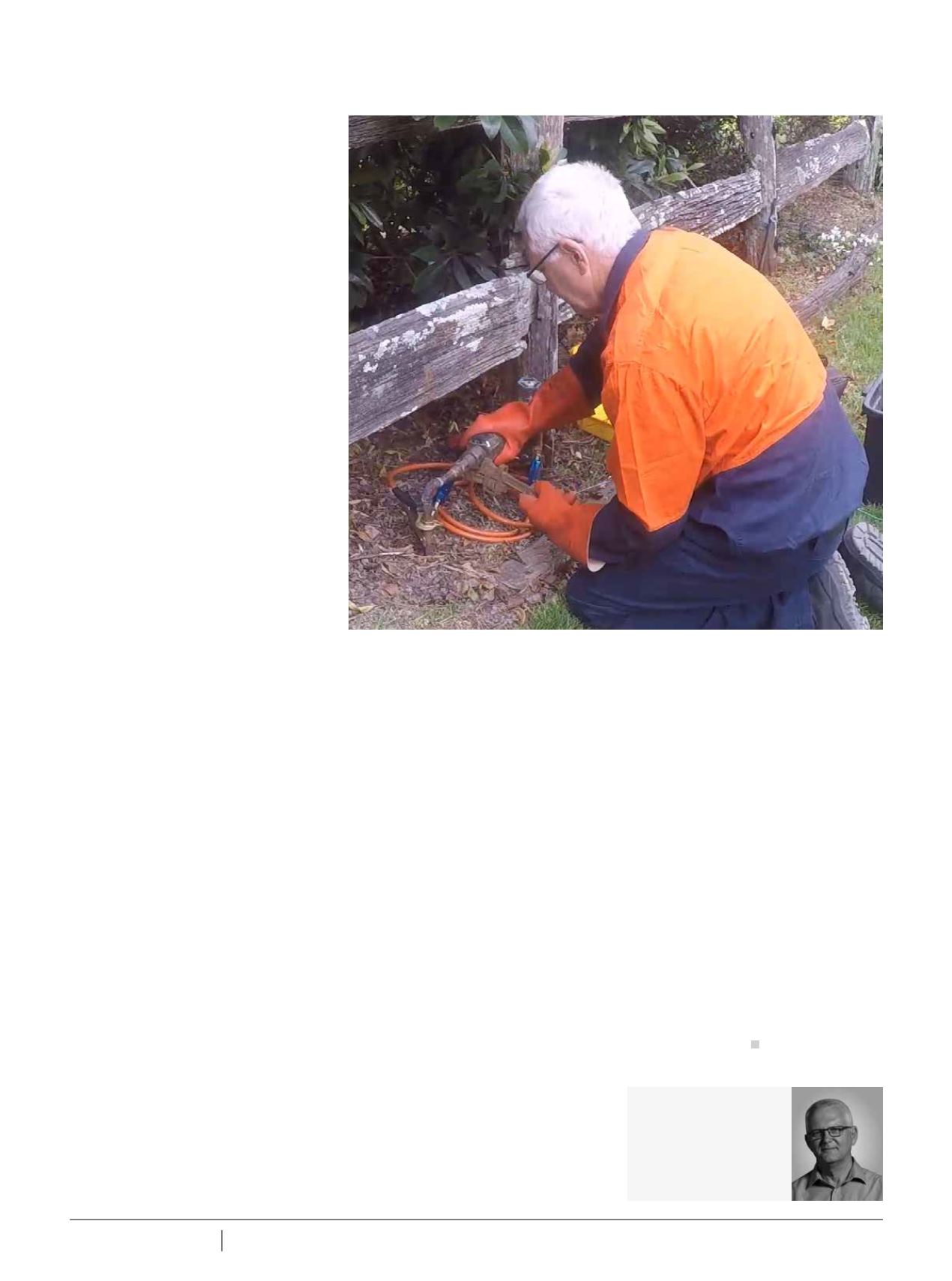

A water meter being changed safely using appropriate controls.